Double-Suction Horizontal Split Centrifugal Pump for Pump Station

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double-Suction Horizontal Split Centrifugal Pump for Pump Station

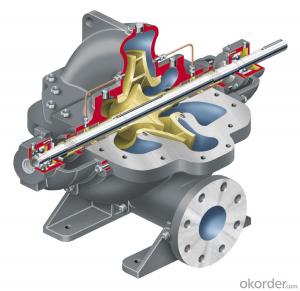

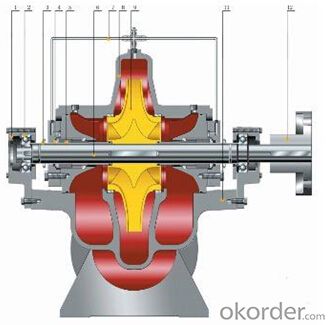

1.Structure of Double-Suction Horizontal Split Centrifugal Pump for Pump Station Description

The Single Stage Double Suction Water Pump is designed for pump station, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Double-Suction Horizontal Split Centrifugal Pump for Pump Station

• Compact structure

• Attractive design

• High efficiency, steady performance

• big capacity, medium pressure

• High concentricity of components

3. Double-Suction Horizontal Split Centrifugal Pump for Pump Station Images

4. Double-Suction Horizontal Split Centrifugal Pump for Pump Station Specification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

5.FAQ

①What is the applications?

Besides irrigation and drainage pumping Station, the Single Stage Double Suction Split Casing Centrifugal Pump also can be used for Circulation water for air-condition, water supply for industry and building, and other waterworks.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q: A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- According to the water quantity form fire flow water supply system fire safety in high-rise building fire hydrant pump lift is 10L/s, accurate algorithm is to say after a simple calculation with each indoor hydrant flow is two 5L/s bolt so to get the most unfavorable point for the calculation unit to calculate the minimum requirements, with the most unfavorable point suppository pressure specifications 0.07MPa, partial loss of the most unfavorable line and the line (according to the equivalent length) and loss (according to the material resistance coefficient), and finally the pump head loss of gravity difference. But we just calculate the construction elevation difference multiplied by 110% to 120% to determine the head {there is a need to know is: conversion head (m), (kg) and MPa kg 1MPa=10 kg = 100m is the vertical water column on unit area pressure conversion

- Q: How to install, operate and maintain the pipeline booster pump?

- The motor coil is provided with a safety protector, and when the pump is out of order or the water is not pumped, the motor can automatically break down when the temperature of the motor exceeds the prescribed value, and the motor can automatically resume operation after the temperature rise of the motor is decreased. The booster pump motor is a capacitor running type motor. When the pump leaves the factory, the rotation direction has been adjusted. If you need to replace the capacitor or re connect, press the arrow direction on the pump body to mark the connection. To ensure safety, use the three - core safety socket with ground wire.

- Q: What are the starting and stopping procedures for centrifugal pumps?

- Before using the centrifugal pump, the operation instructions of the centrifugal pump shall be read carefully and the specific operation procedures shall be understood so as to make proper use of the centrifugal pump products. The first step is the operation of centrifugal pump inlet valve of centrifugal pump centrifugal pump for all open cavity filled with liquid, close the outlet valve, start the motor, the motor speed is normal, can gradually open the outlet valve, to adjust to the desired condition. Pay attention to self suction centrifugal pump starts to open the exhaust valve, outlet valve should be opened quickly in the normal operation of the motor, to prevent air inlet pipe off caused by cavitation phenomenon produces centrifugal pump, centrifugal pump vibration phenomenon leads to noise of the smoke is not on the water.

- Q: What are the application areas of pumps?

- 1, urban water supply 2, sewage system 3, civil and construction systems 4, agricultural water conservancy system 5, power station system6. Chemical system 7, petroleum industry system 8, mine metallurgy system 9, light industry system 10, ship system

- Q: Why can the centrifugal pump hold down the pressure?

- The centrifugal pump can hold pressure because of the suction pipe in the pump at the entrance of a non-return valve (valve).

- Q: Rules for operation of centrifugal pumps

- 3, start the pump, wait until the speed reaches the normal speed, slowly open the outlet valve, observe the ammeter at the same time, and control the current in the rated current range of the motor.4, the operation requires smooth operation of water pumps, no abnormal noise, no pressure fluctuations. The abnormal situation should be stopped in time.

- Q: Water pump spoon pipe for power plantWhich hero can tell me what is the water pump spoon tube ah? And its role

- The spoon pipe is not a feed pump, but also is an adjusting oil inlet device of a hydraulic coupler matched with a feed pump

- Q: The working principle of magnetic pump

- Working principle of magnetic pumpN of the magnet (n is even) arranged according to the laws in the magnetic clutch assembly inside and outside the magnetic rotor, the magnet part consisting of magnetic coupling system. When the inside and outside the two poles in different relative displacements, two poles between the angle phi = 0, the lowest energy magnetic system; when rotates to the relative displacement is two poles, pole angle between phi = 2 pi /n, the magnetic system of magnetic energy. Remove the external force, due to the magnetic system of magnetic poles repel each other, magnetic magnet will return to the lowest energy state. So magnets in motion, driven by the magnetic rotor.

- Q: What are the main performance parameters of the pump?

- The main performance parameters of the pump are:The energy obtained by pumping a unit weight of liquid through a pump. In H, the unit is m.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- Regeneration of the filter medium is required to regain the filtration capacity of the medium. The regeneration process is mainly accomplished by the backwashing pump (the backwash pump is not a special pump, referring to the pump for the completion of the process). The working principle is through the cleaning liquid from the downstream of the filter into the backwash pump (alkali, acid and water), reverse flushing filter medium, cleaning liquid discharged from the upstream, this process can be attached to the dielectric surface and internal impurities washed away.

Send your message to us

Double-Suction Horizontal Split Centrifugal Pump for Pump Station

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords