Cylindrical roller Bearings, Cylindercal roller bearing,

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Cylindrical roller bearings:

Cylindrical roller bearings belong to separable bearings, whose inner and outer rings are linearly contacted with rollers. They have small friction coefficient, bigger capacity of bearing radial load and are applicable to both bearing heavy load and impact load and high-speed rotation. Cylindrical roller bearings have the advantages of compact structure, strong stiffness, big bearing capacity, small deformation after loaded etc.

CNBM has already successfully developed split cylindrical roller bearings which can be freely installed at any time and any place, to meet the demand of driving and conveying rollway bearings at cooling area of continuous casting. CNBM also can provide special cylindrical roller bearings according to requirement of customers.

Product Application:

- Iron and steel metallurgical industry

- Medium and large motor

- Generator

- Combustion engines

- Machine tool spindle

- Speed reducer

- Loading and unloading machinery and all kinds of industrial machinery

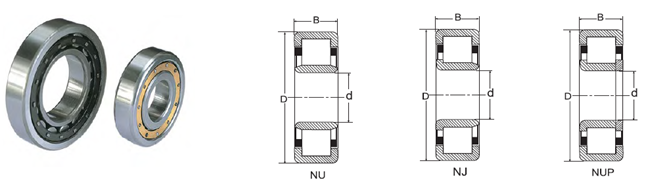

Single row cylindrical roller bearings

- NU, N single row cylindrical roller beaings

NU type and N type allows axis relative the cage within the scope of certain to do axial movement, it would adapt for thermal expansion or installation error caused by the shaft and housing relative position changes, they suit to use for free end bearing. Because they can not limit shaft and the shell axial displacement, and can only bear the radial load.

- NJ, NF single row cylindrical roller bearings

Both NJ and NF can bearing single direction axial load in a certain extent.

- NUP single row cylindrical roller bearings

NUP type bearings with double outer rid, single inner rid and loose rid, this design is possible to limit the axial displacement of the shaft or the housing in double direction within the scope of the axial clearance. in addition they mainly used to bear radial load, also can withstand diameter, the axial union load. Therefore this NUP suitable for fixed end bearings.

- NCL…V single row cylindrical roller bearings

No outer rim but with double lock ring without cage cylindrical roller bearing.

The bearing no cage, roller number is more, and size of the same other cylindrical roller bearing is able to withstand the big radial direction load, but its limit rotational speed is low. The bearing inner ring and outer inseparable, cannot install respectively, can limit shaft or housing of the two directions of the axial displacement in bearing axial clearance within the limit.

| Bearing No. | d | D | B(mm) | Weight(kg) | Bearing No. | d | D | B(mm) | Weight(kg) | |||||

| NU202 | 15 | 35 | 11 | 0.047 | ||||||||||

| NU203 | 17 | 40 | 12 | 0.068 | ||||||||||

| NU204 | 20 | 47 | 14 | 0.110 | NU304 | 20 | 52 | 15 | 0.150 | |||||

| NU205 | 25 | 52 | 15 | 0.130 | NU305 | 25 | 62 | 17 | 0.240 | |||||

| NU206 | 30 | 62 | 16 | 0.200 | NU306 | 30 | 72 | 19 | 0.360 | |||||

| NU207 | 35 | 72 | 17 | 0.300 | NU307 | 35 | 80 | 21 | 0.480 | |||||

| NU208 | 40 | 80 | 18 | 0.370 | NU308 | 40 | 90 | 23 | 0.650 | |||||

| NU209 | 45 | 85 | 19 | 0.430 | NU309 | 45 | 100 | 25 | 0.900 | |||||

| NU210 | 50 | 90 | 20 | 0.480 | NU310 | 50 | 110 | 27 | 1.150 | |||||

| NU211 | 55 | 100 | 21 | 0.660 | NU311 | 55 | 120 | 29 | 1.450 | |||||

| NU212 | 60 | 110 | 22 | 0.810 | NU312 | 60 | 130 | 31 | 1.800 | |||||

| NU213 | 65 | 120 | 23 | 1.050 | NU313 | 65 | 140 | 33 | 2.250 | |||||

| NU214 | 70 | 125 | 24 | 1.150 | NU314 | 70 | 150 | 35 | 2.750 | |||||

| NU215 | 75 | 130 | 25 | 1.250 | NU315 | 75 | 160 | 37 | 3.300 | |||||

| NU216 | 80 | 140 | 26 | 1.500 | NU316 | 80 | 170 | 39 | 3.950 | |||||

| NU217 | 85 | 150 | 28 | 1.900 | NU317 | 85 | 180 | 41 | 4.700 | |||||

| NU218 | 90 | 160 | 30 | 2.350 | NU318 | 90 | 190 | 43 | 5.450 | |||||

| NU219 | 95 | 170 | 32 | 2.850 | NU319 | 95 | 200 | 45 | 6.250 | |||||

| NU220 | 100 | 180 | 34 | 3.450 | ||||||||||

| NU221 | 105 | 190 | 36 | 4.000 | ||||||||||

| NU222 | 110 | 200 | 38 | 4.800 | ||||||||||

- Q:What are the reasons for the use of tapered roller bearings and angular contact ball bearings?

- Selection of bearings in accordance with the theory and practice of judgment, that is, bearing capacity and the form of movement and load factors are different. That is, the role of the two bearings

- Q:Can angular contact ball bearings be adjustable?

- May not。Self-aligning ball bearings and spherical roller bearings are adjustable.

- Q:The difference between ultra high speed angular contact ball bearings and other plain bearings

- Yue bearing features:1. low heating and high speed.X products 2. using heat and friction wear is made of SHX material production, to realize high speed and long life.3., according to different uses, established a different contact angle and ball material specifications of the powerful lineup.4., with wide sealing ring, compared with open bearings, grease life increased to 1.7 times, to achieve a long life.Compared with plain bearings, plain bearings only play the role of reducing the friction coefficient in the power transmission process and keeping the center of the shaft fixed when the parts on the shaft produce relative motion with each other. Low wear resistance, short life, performance is far less than ultra-high speed angular contact ball bearings, but considering the price, the average bearing price may be lower.

- Q:Two angular contact ball bearings, the use of clearance problems

- No adjustment required,DB: back to backDF: face to faceDT: series connectionSU: single arbitrary combinationDU: any combination of two bearings.

- Q:What are the differences between angular contact bearings AC and A and C?

- Angular contact bearings common suffix has AC, C and B, AC said nominal contact angle a is 25 degrees, C is 15 degrees, B is 40 degrees.

- Q:How to install angular contact ball bearings?

- The installation of angular contact ball bearings is more complicated than deep groove ball bearings. It is mostly installed in pairs, and preload is necessary. Well installed, can make the host work accuracy, bearing life greatly improved; otherwise, not only the accuracy can not meet the requirements, the life will be affected.The installation form of angular contact ball bearings, a series of face to face and back to back, three. (two back-to-back wide end bearing relative) installation, bearing contact angle line along the axis of rotation diffusion direction, bearing angle can increase the radial and axial rigidity, maximum deformation resistance; face to face (two relatively narrow end bearing) installation, bearing contact angle of the rotary axis line towards the direction of its convergence. To the point of less rigidity. Because of the inner ring of the bearing outer ring out, when pressing the outer ring two bearing together, the original gap ring is eliminated, can increase the bearing preload; tandem arrangement (two wide end bearing in one direction) when installing the bearing contact angle and parallel lines in the same direction, the two share the same bearing the direction of the work load. However, in order to ensure the axial stability of the installation, the two pairs of bearings arranged in series must be installed opposite the ends of the shaft in order to ensure the axial stability of the installation.

- Q:How many angles are there in angular contact ball bearings? How many degrees are they?

- A stands for 30 degrees, A5 stands for 25 degrees, B stands for 40 degrees, and C stands for 15 degreesThe new Seiko NSK serves you!

- Q:Angular contact ball bearings, how to judge the size of the mouth?

- Judge the size of the mouth, of course, big mouth is large, that is, the edge of the slope for the side of the big mouth.

- Q:What is the difference between deep groove ball bearings and angular contact ball bearings?

- Deep groove ball bearings and angular contact ball bearings are not the same

- Q:What does angular contact ball bearing 70216AC mean?

- Name = General rolling bearing type code No.Standard = excerpt from GB/T 272-1993-----------------------------------------------------------Bearing type = angle contact ball bearingCode =7The original code name is =6Bearing type = angle contact ball bearingDimension series code = (0) 2After two, 16, bearing nominal diameter 16 * 5=80mmName = internal structure codeStandard = excerpt from GB/T 272-1993

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cylindrical roller Bearings, Cylindercal roller bearing,

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords