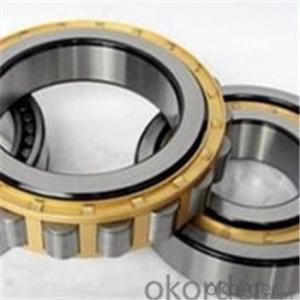

Cylindrical Roller Bearing , Chinese Factory NUP 205 E

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Cylindrical roller and race for line contact bearing. Load capacity is big, mainly bear radial load .

1. Friction coefficient is small, suitable for high speed limit speed close to deep groove ball bearings

2.N and NU type axial movement, can adapt to shaft caused by thermal expansion or installation error and shell the change of relative position, can be used for free end bearing

3. On the shaft or hole of the processing and the demand is higher, bearing outer axis relative deflection after installation to be kept under strict control, so as not to cause contactstress concentration

4. Inner ring or outer ring separable, easy to install and remove

Specification | Model No.: NUP 205 E |

Brand Name: OEM | |

Size:25*52*15mm | |

Net weight: 0.140kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

Packaging & Delivery

Packaging Details: | plastics wrapping bearings - wrapping papers - polywoven bag - carton for outside package - wooden box /According to your order |

Delivery Detail: | 30-40days/according to your order |

Product Applications:

Cylindrical Roller Bearing Application Flied:Rolling Mills,Crusher,Mining

Metallurgy Petroleum,Chemical Industry,Engineering Machinery,Port,Oil,Gas,

Wind,Agriculture,Lathe,CNC,Steel Works,Electrical Machinery,Axle/Limber,

Tractor,Autocar,Crude Oil Engine and so on.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

- Q: NSK cylindrical roller bearings EW/EM series of differences and characteristics

- M international is called brass retainerThis can be a question, just ask, for reference only

- Q: KOYO cylindrical roller bearings, //KOYO cylindrical roller bearings, how to determine the accuracy level?

- Bearing accuracy grade standards for, divided into 0, 6X, 6, 5, 4, 2, six grades.The accuracy of bearings is increased in order of magnitude 0, which is adequate for general 0, but requires 5 or higher accuracy when used in other conditions or situations.In most cases, it is sufficient to apply KOYO bearings (tolerance grade PN) with general dimensional accuracy and rotational accuracy. When higher requirements are required, the bearings require higher levels of accuracy, for example, the spindle axis of the machine toolBearing. In order to achieve higher precision requirements, the standard specifies the tolerance levels of P6, P6X, P5, P4 and P2. KOYO also specified P4S, SP and UP tolerances for some special bearings in accordance with company standards.

- Q: What are the differences between cylindrical roller bearings nu208m and nu208em?

- E means "reinforced", "rolling", "thickening", "change", "change".. Hope to adopt!!

- Q: Attention problems of cylindrical roller bearings

- High temperatures often indicate that cylindrical roller bearings are in exceptional condition. High temperature is also harmful to bearing lubricants. Sometimes the bearing is overheated and can be attributed to the lubricant in the bearing. If the bearings are longer than the temperature of 125 degrees, even the transfer will reduce the bearing life. The causes of high temperature bearings include: insufficient lubrication or excessive lubrication, impurities in the bearing raceway, extreme high speed, long term overload operation of bearings, etc..

- Q: What are full cylindrical roller bearings?

- Full capacity roller bearings are divided into double row full load roller, single row full roller, outer spherical roller, CARB bearingsI am a bearing manufacturer, factory direct marketing, welcome inquiry cooperation. Contact information on personal data

- Q: Is the roller bearing and the bearing chamber movable in the tapered rotor motor?

- E in cylindrical roller bearing is the meaning of improving internal cage design, similar to the SKF cylindrical roller bearing EC form, this type of bearing than without E, is to strengthen the design, the roller is filled more larger to increase the load. From the load point of view, it is better to choose E.

- Q: For example, NU, NJ, N, RNU, NUP, NF, NO, NN, RN, what do you mean, who can tell me about that hero?

- N outer ring without edge, inner ring double edgeRNU no inner ring, NU typeNUP outer ring, double retaining ring, inner ring, single edge, with flat retaining ringNF outer ring, single edge, inner ring, double edgeNO doesn't know

- Q: Cylindrical roller bearings, in the grease after the operation for a short period of time, the grease was thrown out (thrown to the end cap), resulting in roller and raceway between the lack of grease, lubrication poor. Decomposition found that the roller has round circumferential friction marks, but also on the roll, but compared to the roller is very slight. And there are relatively sound bearings, abnormal sound.Is this phenomenon normal? What if it doesn't work? What was the reason? What's the solution? StopThanks for your help!Assuming the grease is no problem, viscosity, consistency, selection is no problem If exclusion is the problem of grease, what other reasons can this be the case? ?

- I carefully read your question, I think the following talk about my views, this system from the point of view of the design, are questionable, at least the following several aspects of the design problem, put forward for reference only:1, the system does not have [oil seal], can only say that the design of the beginning of the consideration is somewhat lacking.2, [] general should choose roller bearing oil bath lubrication [], [] instead of grease, because the roller in the roller bearing [] [] in the grease, the grease has a strong crowding out of [], which leads to bad lubrication.3, [] grease generally rely on the mechanism of working temperature Shenglai improve grease liquidity, but need to have [] to seal and prevent the overflow of grease, no seal mechanism design [] summary, this place is only [] However, boundary lubrication, boundary lubrication [] [generally used for oil lubrication], [grease] rather than

- Q: The thrust cylindrical roller bearings do not need the bearing seat, and the thrust bearings, shaft rings and seat rings on our unit are all in the bearing seat, often broken. The rotation of the 1. shaft in the bearing seat will not be affected, moreover, the shaft will have radial runout. 2. do not use the bearing seat, usually how to refuel?.Are there any field installation drawings or data on thrust bearings?. Thanks a million!

- In general, this kind of bearing does not use the bearing seat

- Q: How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- 3, the bearing clearance in different conditions: the bearing clearance can be changed under different conditions, in particular, can be divided into: 1) the original clearance: the original bearing clearance refers to the complete installation in front of the machine after the bearings, the clearance in a free state of the. In fact, the original clearance is not to be measured by measurement, so the original clearance is often replaced by a test clearance. The inspection is in clearance inspection status, applied in measuring load conditions, clearance data instruments detection and, strictly speaking with the original bearing clearance is not the same, but little difference in the readings on the two in general, so it can replace each other without causing much error. 2) effective clearance: effective clearance, or work clearance, refers to the bearing in the installation of the host, in a certain load, to a certain temperature rise in a stable state of operation, bearings exist in the actual clearance. Obviously, the effective clearance is smaller than the original clearance.And 4, bearing clearance: clearance of bearing is to ensure that the bearings are to operate flexibly without blocking, but also requires that can ensure the bearing running smoothly, the bearing axis has no significant settlement, and the number of rolling elements bear the load as much as possible. Therefore, the clearance of the bearing has a great influence on the dynamic performance of the bearing (noise, vibration and friction) and the rotation accuracy, and the carrying capacity (wear and fatigue) of the bearing.

Send your message to us

Cylindrical Roller Bearing , Chinese Factory NUP 205 E

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords