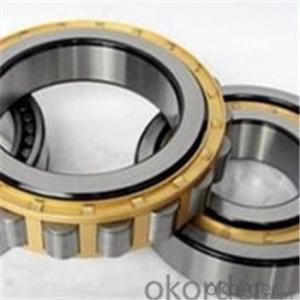

Cylindrical Roller Bearing , Chinese Factory N 205 M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Cylindrical roller and race for line contact bearing. Load capacity is big, mainly bear radial load .

1. Friction coefficient is small, suitable for high speed limit speed close to deep groove ball bearings

2.N and NU type axial movement, can adapt to shaft caused by thermal expansion or installation error and shell the change of relative position, can be used for free end bearing

3. On the shaft or hole of the processing and the demand is higher, bearing outer axis relative deflection after installation to be kept under strict control, so as not to cause contactstress concentration

4. Inner ring or outer ring separable, easy to install and remove

Specification | Model No.: N 205 E |

Brand Name: OEM | |

Size:25*52*15mm | |

Net weight: 0.145kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

Packaging & Delivery

Packaging Details: | plastics wrapping bearings - wrapping papers - polywoven bag - carton for outside package - wooden box /According to your order |

Delivery Detail: | 30-40days/according to your order |

Product Applications:

Cylindrical Roller Bearing Application Flied:Rolling Mills,Crusher,Mining

Metallurgy Petroleum,Chemical Industry,Engineering Machinery,Port,Oil,Gas,

Wind,Agriculture,Lathe,CNC,Steel Works,Electrical Machinery,Axle/Limber,

Tractor,Autocar,Crude Oil Engine and so on.

- Q: Why are cylindrical roller bearings suitable for traveling support?

- Should be the inner ring and the outer ring without the edge of the can do moving support.

- Q: How much is the axial force of double row cylindrical roller bearings? How is it calculated?

- The cylindrical roller bearings have ribs can withstand certain axial force, the axial force for cylindrical but still belongs to the non normal stress, can cause early failure of the bearing, it is generally not given the axial bearing capacity, no formula

- Q: How are the twin row cylindrical roller bearings classified?

- Classification of double row cylindrical roller bearings:The NN0000 type cylindrical roller bearingsThe bearings are compact in structure and small in deformation under load, so they are especially suitable for the support of the spindle of machine tools. Because of its no outer wall, so you can install the outer ring and the inner ring assembly respectively (with roller and cage), does not limit the axial displacement of the shaft or housing, compared with the single row cylindrical roller bearing with the same radial size, can bear larger radial load.

- Q: what does that mean? Please enlighten master, thank you.

- Hello, E on behalf of hanging behind the cage (black) steel cage; EM stands for copper holder.

- Q: Can the Nu and N type NJ NUP cylindrical roller bearings bear axial force?

- The answer upstairs is clear. Such bearings can not be designed with axial force. In use, the inner and outer rings of the bearing can have larger axial displacement, and the aim is to compensate the length change caused by the rotating part of the two bearing due to the temperature rise.

- Q: Can you make it clear? I don't understand. Thank you for being here first.

- The rollers refer to the rolling bodies as cylinders and similar cylindrical shapes, such as short columns, long columns, tapered rollers, spherical rollers, etc..

- Q: My notes is the former has a taper hole on the cone position preload, the latter is a nut. But the online information seems a little different. Are the preload methods for two direction thrust angular contact bearings and angular contact ball bearings the same?

- Dissimilarity! The former is mainly used as the support of the shaft with larger load. The main prevention is the radial runout, which is usually used individually, so there is not much demand for the preload.

- Q: What are full cylindrical roller bearings?

- Full cylindrical roller bearingCommon cylindrical roller bearings1, single row full cylindrical roller bearingsNCFNJG2 、 double row full cylindrical roller bearingNNCLNNCFNNCNNFTwo, not common full cylindrical roller bearings1, full spherical cylindrical roller bearings2, CARB ring roller bearings

- Q: How should I find the concentricity of cylindrical roller bearings after installation?

- Any form of assembly, adjustment center is a very troublesome thing, but also in the measuring installation is not very complete, the usual method is to in the base below (or below) thin copper with different thickness, until you feel better, but each installation to re adjust. So, in the machining process, try to use special fixtures and parts drawing in tol and other measures to avoid such a remedy".

- Q: Cylindrical roller bearings, in the grease after the operation for a short period of time, the grease was thrown out (thrown to the end cap), resulting in roller and raceway between the lack of grease, lubrication poor. Decomposition found that the roller has round circumferential friction marks, but also on the roll, but compared to the roller is very slight. And there are relatively sound bearings, abnormal sound.Is this phenomenon normal? What if it doesn't work? What was the reason? What's the solution? StopThanks for your help!Assuming the grease is no problem, viscosity, consistency, selection is no problem If exclusion is the problem of grease, what other reasons can this be the case? ?

- The higher the speed, the greater the centrifugal force, this point should be mastered. If the grease of good quality, from the bearing chamber to consider the change of the bearing chamber space, the sides of the bearing sealed by using injection nozzle gun grease can improve the lubrication condition.

Send your message to us

Cylindrical Roller Bearing , Chinese Factory N 205 M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords