Bearings four row cylindrical roller, model FC2234120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bearings four row cylindrical roller, model FC2234120

Four row cylindrical roller bearings

Four row cylindrical roller bearing is usually use in rolling mill’s work roll or back-up roll. It mainly take much radial load, which is extensively used on the work roll of wire rod mill, section mill and bloomer mill , as well as the back-up roll of dressing machine, cold rolling mill and hot rolling mill.There are three kinds of structures: FC, FCD, FCDP. There are three grades for tolerance : 0 , 6 , 5.

FC: double outer ring, single inner ring, inner ring without rid;

FCD: double outer ring, double inner ring, inner ring without rid;

FCDP:double outer ring, double inner ring, inner ring without rid

★ Product Features:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

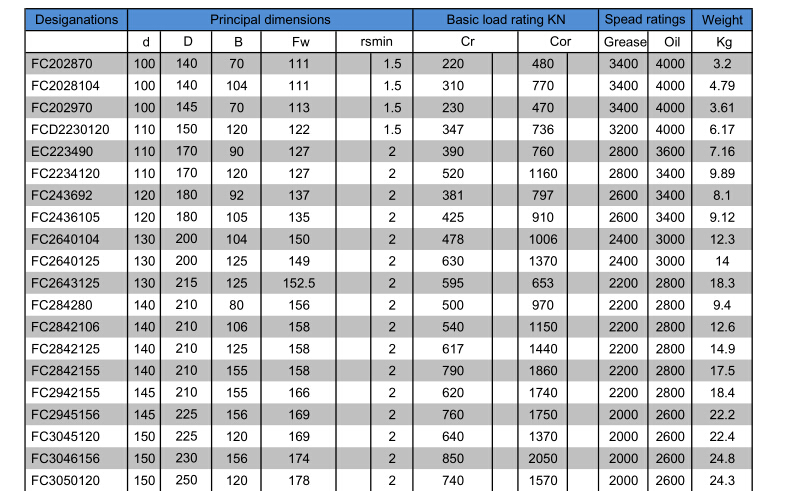

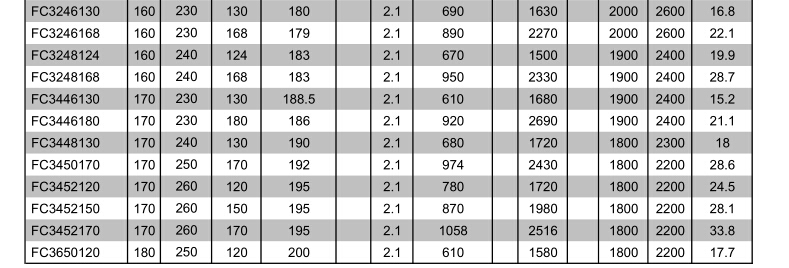

Four Cylindrical Roller Bearings Catalugue

- Q: NSK cylindrical roller bearings EW/EM series of differences and characteristics

- M international is called brass retainerThis can be a question, just ask, for reference only

- Q: Why are cylindrical roller bearings suitable for traveling support?

- Cylindrical roller bearings without inner sides of the inner ring or outer ring, whose inner and outer rings can be moved relative to the axial direction, so they can be used as free end bearings.

- Q: Double row full cylindrical roller bearings, NNCF5008 installation, we need to pay attention to the direction of it?

- Double row cylindrical roller bearings have no directionality, so they do not need to pay attention to the direction! However, it should be noted that the inner ring and outer ring should be positioned separately to prevent axial movement!

- Q: Can the Nu and N type NJ NUP cylindrical roller bearings bear axial force?

- The answer upstairs is clear. Such bearings can not be designed with axial force. In use, the inner and outer rings of the bearing can have larger axial displacement, and the aim is to compensate the length change caused by the rotating part of the two bearing due to the temperature rise.

- Q: Attention problems of cylindrical roller bearings

- 4, when the interference is large, the oil bath heating or inductor heating bearings can be used to install the heating temperature range of 80 degrees -100 DEG C, the maximum can not exceed 120 degrees centigrade. At the same time, the nut or other appropriate method is used to fasten the bearing so as to prevent the contraction of the bearing in the direction of width and to create a gap between the collar and the shaft shoulder. 5, single row tapered roller bearings installed, the final adjustment should be clearance. The clearance value shall be determined according to the working conditions and the magnitude of the interference fit. Test shall be carried out when necessary. Double row tapered roller bearings and pump shaft bearings have been adjusted for clearance at the factory, and no adjustment is necessary during installation. 6, the bearing should be installed after the rotation test, the first for the rotary shaft or bearing box, without exception, then the power for no load, low speed operation, and then gradually increase as the functioning of the rotation speed and load, and to detect noise, vibration and temperature, abnormal, should stop running and check. The running test is normal and can be used before delivery.

- Q: What are the components of cylindrical roller bearings?

- The utility model has the advantages of convenient installation and disassembly, especially when the inner, outer ring and the shaft and the shell are in interference fit. Such bearings are generally only used to bear radial load, only the inner and outer ring with single block bearings can bear less axial load or larger intermittent axial load.

- Q: The Russian bearing suffix No. ZST is a cylindrical roller bearing

- The suffix code is not used to distinguish the bearings, but it helps to explain the structure of the bearings and the material.

- Q: Why are there no double row cylindrical roller bearings in the mechanical design manual?

- So under normal circumstances, the bearing bore and the shaft is no gap.But do you mean that the inner ring and the shaft of the bearing are fixed,

- Q: How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- 3, the bearing clearance in different conditions: the bearing clearance can be changed under different conditions, in particular, can be divided into: 1) the original clearance: the original bearing clearance refers to the complete installation in front of the machine after the bearings, the clearance in a free state of the. In fact, the original clearance is not to be measured by measurement, so the original clearance is often replaced by a test clearance. The inspection is in clearance inspection status, applied in measuring load conditions, clearance data instruments detection and, strictly speaking with the original bearing clearance is not the same, but little difference in the readings on the two in general, so it can replace each other without causing much error. 2) effective clearance: effective clearance, or work clearance, refers to the bearing in the installation of the host, in a certain load, to a certain temperature rise in a stable state of operation, bearings exist in the actual clearance. Obviously, the effective clearance is smaller than the original clearance.And 4, bearing clearance: clearance of bearing is to ensure that the bearings are to operate flexibly without blocking, but also requires that can ensure the bearing running smoothly, the bearing axis has no significant settlement, and the number of rolling elements bear the load as much as possible. Therefore, the clearance of the bearing has a great influence on the dynamic performance of the bearing (noise, vibration and friction) and the rotation accuracy, and the carrying capacity (wear and fatigue) of the bearing.

- Q: Why should the main shaft be coupled with double row cylindrical roller bearings?

- Because double row cylindrical roller bearings with high carrying capacity, high precision, separation, easy installation and disassembly, mainly used in lathes, milling machines, machining centers and other high-precision machine tool spindle. Hope to be of help to you.

Send your message to us

Bearings four row cylindrical roller, model FC2234120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords