Bearings four row cylindrical roller FC2234120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

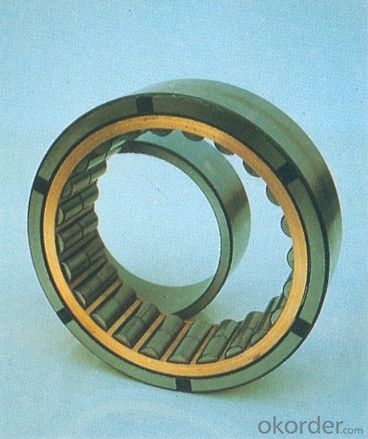

Four row cylindrical roller bearings

Four row cylindrical roller bearing is usually use in rolling mill’s work roll or back-up roll. It mainly take much radial load, which is extensively used on the work roll of wire rod mill, section mill and bloomer mill , as well as the back-up roll of dressing machine, cold rolling mill and hot rolling mill.There are three kinds of structures: FC, FCD, FCDP. There are three grades for tolerance : 0 , 6 , 5.

FC: double outer ring, single inner ring, inner ring without rid;

FCD: double outer ring, double inner ring, inner ring without rid;

FCDP:double outer ring, double inner ring, inner ring without rid

★ Product Features of bearings:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application of bearings:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

Four Cylindrical Roller Bearings Catalugue

- Q: NSK cylindrical roller bearings EW/EM series of differences and characteristics

- M international is called brass retainerThis can be a question, just ask, for reference only

- Q: How are the twin row cylindrical roller bearings classified?

- Classification of double row cylindrical roller bearings:The NN0000 type cylindrical roller bearingsThe bearings are compact in structure and small in deformation under load, so they are especially suitable for the support of the spindle of machine tools. Because of its no outer wall, so you can install the outer ring and the inner ring assembly respectively (with roller and cage), does not limit the axial displacement of the shaft or housing, compared with the single row cylindrical roller bearing with the same radial size, can bear larger radial load.

- Q: what does that mean? Please enlighten master, thank you.

- You should say that the Japanese NSK bearings? NSK, N216, E stands for high load cylindrical roller bearings, N216 EM, which represents high load cylindrical roller bearings, copper alloy solid cage. E, which means strengthening the design, so the load capacity of bearings is better than without E.

- Q: What is the limit speed and rated dynamic load of NSK full M40-19g cylindrical roller bearings, HTF?

- D - tapered roller bearings with a contact angle of 28 degrees. C, CA (with solid brass cage), CD (with stamping cage), spherical roller bearing with high load. E -- high load cylindrical roller bearing. H - thrust roller bearing high load. J - tapered roller bearings of the outer raceway, the small end diameter, angle, outer ring width is consistent with the provisions of ISO. (2) material G - ring, rolling body is carburizing steel. H - ring, roll for stainless steel. (3) holder M - copper alloy solid cage. T - synthetic resin cage. W - press holder. V - no cage. (4) sealing ring, dust cover Z, ZS - one side with steel plate dust cover. ZZ, ZZS -- dust cover for two side steel plate. D, DU - one side contact rubber ring. DD, DDU -- two faced contact rubber ring. V - one with a non-contact rubber ring. VV -- two side non-contact rubber sealing ring. (5) ring shape K - taper hole, taper 1:12. K30 -- taper hole, taper 1:30. E - there is a notch or oil hole in the ring. E4 - oil tank with oil holes on the outer ring. N -- outside outer diameter band stop groove. NR -- outer ring, outer band, stop groove, stop ring.

- Q: My notes is the former has a taper hole on the cone position preload, the latter is a nut. But the online information seems a little different. Are the preload methods for two direction thrust angular contact bearings and angular contact ball bearings the same?

- The latter is mainly used as a precision screw shaft for the radial motion and axial runout requirements are very strict, generally used when they are two back-to-back, when pre tightening have strict requirements, general requirements for the radial motion and axial runout should not exceed 5 per thousand mm.

- Q: cylindrical roller bearings N210 20Deep groove ball bearings 6120, self-aligning ball bearings 1210, cylindrical roller bearings N210 in the same radial force conditions, the life expectancy of the three levels and how to compare? What is the cause of the high and low?

- The cylindrical roller bearings are in line contact with the outer ring of the bearing, and have the largest contact surface with the outer ring of the bearing. And the large contact surface means that in the same radial force, the same speed, friction, and thus generate more heat, and thus affect the life.

- Q: Can cylindrical roller bearings bear high temperature?

- A class of grease, temperature is not more than 120 degrees, and then high temperature will lose lubrication performance, leading to the bearings can not work, in fact, bearing itself can withstand high temperature.

- Q: Cylindrical roller bearings, in the grease after the operation for a short period of time, the grease was thrown out (thrown to the end cap), resulting in roller and raceway between the lack of grease, lubrication poor. Decomposition found that the roller has round circumferential friction marks, but also on the roll, but compared to the roller is very slight. And there are relatively sound bearings, abnormal sound.Is this phenomenon normal? What if it doesn't work? What was the reason? What's the solution? StopThanks for your help!Assuming the grease is no problem, viscosity, consistency, selection is no problem If exclusion is the problem of grease, what other reasons can this be the case? ?

- Normal phenomenon: your choice of grease is too thin, choose a high degree of consistency. 2: mechanical revolution is too fast. 3: Grease adhesion is not high. Three possibilitiesHangzhou Xingang Petrochemical Co., Ltd. specializes in producing and selling grease and lubricating oil. Tip answer

- Q: Can it be used for axial alignment? Forty-fiveWhat is the function of the flat retaining ring of NUP cylindrical roller bearings with flat retaining rings? Can it be used for axial alignment?How much axial force can I bear then?You are the ZWZ? Can you make a friend?!How much axial force can you bear? Do you have a formula or a recommended value?NUP is needle roller bearings, brothers, I dialed the wrong number:What is the function of the flat retaining ring of the needle roller bearing with flat ring NUP? Can it be used for axial alignment?There seems to be no experts here, all mixed up

- Yes, the function of the flat ring is to bear the axial force and be used for axial positioning.

- Q: How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- First of all for the bearing clearance calculation is a very complicated problem, because the bearing structure of different types, and the usage of different materials, the temperature of different factors such as the clearance is different, and because of the different structure types and some bearing bearing clearance is divided into radial clearance and axial clearance; also need to pay attention to the bearing clearance is usually divided into the following 1. conditions, clearance before installation, usually refers to the bearing manufacturers factory according to the standard to determine the clearance of bearing clearance. 2., after the installation clearance, because the bearing inner ring and the shaft is interference fit, when the bearings installed on the shaft, its inner ring will be as the amount of interference and expansion, resulting in smaller clearance of bearings. 3. clearance work, because the bearing is affected by load and rotating friction in the work, the temperature will gradually increase, will cause the bearing inner ring further expansion, which will make further changes in bearing clearance. However, the main clearance of the bearing is the largest (minimum) diameter of the raceway of the outer race of the bearing, the largest (minimum) diameter of the rolling body and the largest (smallest) diameter of the raceway of the inner race. For example, cylindrical roller bearings, its largest clearance = outer raceway raceway, maximum diameter of -2* roller minimum diameter - inner raceway minimum diameter derived, and conversely, for the smallest clearance. The average user of bearings actually doesn't need to know that.The other 23226 models should be the spherical roller bearing, not double row cylindrical roller bearing.I hope my answer will be of some help to you!

Send your message to us

Bearings four row cylindrical roller FC2234120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords