Corrugated Sheets /Steel Manufacturer/ /Roofing Application Colour Steel coil/AL-Zn PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Corrugated Sheets Features:

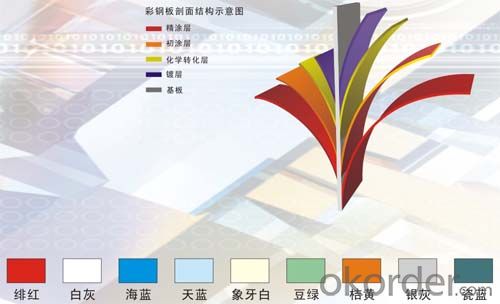

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications Corrugated Sheets :

* Used as roof panel, wall panel in steel structure in warehouse, factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction, animal husbandry, fishery and commerce, etc,

3.Corrugated Sheets information:

Product | Coated Surface Treatment Mental steel |

Base Material | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

Color | All RAL Color,or be customized |

Equipment | Double coating double baking; three coating three painting |

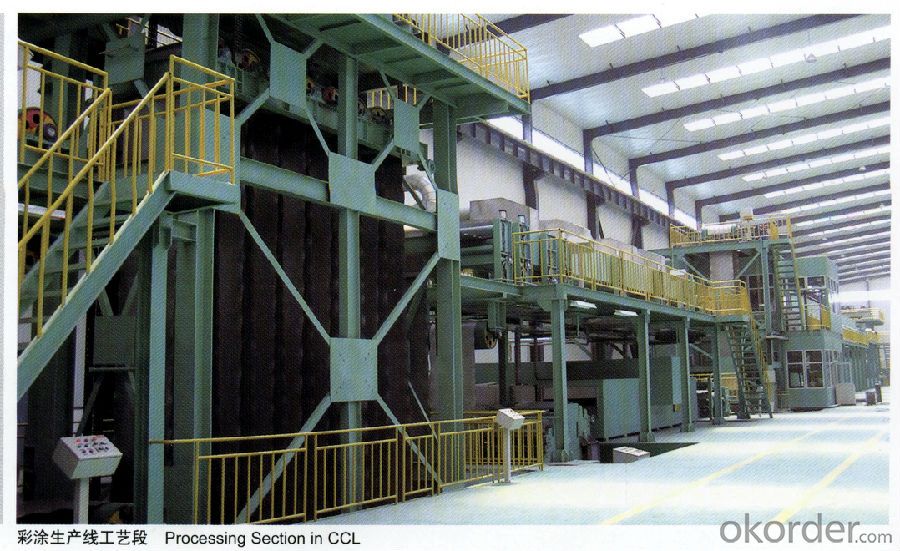

Production Capacity | 500,000 Tons per Year |

Size | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

Zinc Coating | 30g/m2-150g/m2 |

Thickness | Top Side: 10-25 microns; Back Side: 4-8 microns |

Coil Weight | Normally 5 Tons per Coil, aslo as required by customer |

Coil ID | 508mm/610mm |

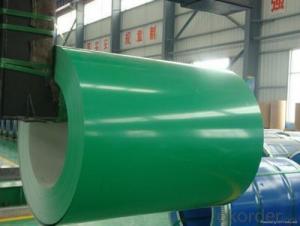

4.Corrugated Sheets image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the industries that consume the most steel?

- Costuuction and auto are most likely the top two.

- Q: I am looking to weld some stainless steel using stainless electrodes. I was told that the arc welder needs to be able to run in DC in order to be able to weld stainless steel. Is this true? Or can you weld stainless steel with stainless electrodes with AC also?

- there are tradeoffs to the various methods you can use. Check out this link for the scoop on what they are and what the settings should be given the material you are using and the type of welder you decide to use.

- Q: What are the advantages of using galvanized steel coils?

- There are several advantages to using galvanized steel coils. Firstly, galvanized steel is highly resistant to corrosion, which means it can withstand exposure to moisture and other harsh environmental conditions without rusting. This makes it a durable and long-lasting material for various applications. Secondly, galvanized steel coils have a protective zinc coating that acts as a barrier against damage and provides excellent structural strength. Additionally, galvanized steel coils are versatile and can be easily formed, welded, and painted, making them suitable for a wide range of industries and projects.

- Q: What are the different types of steel surface finishes for coils?

- There are several types of steel surface finishes for coils, including hot rolled, cold rolled, galvanized, coated, and pickled and oiled.

- Q: What is the strongest steel ever made.

- I'm a civil/structural engineer. ASTM A 416 is one of the strongest steels, with a nominal yield stress of 243,000 psi and design ultimate strength of 270,000 psi. This steel is commonly used in pre-stressing and post-tensioning of concrete structures. See the link below to one manufacturer of strands and bars made with this type of steel.

- Q: How are steel coils processed before they are used in manufacturing?

- Steel coils are processed before they are used in manufacturing through a series of steps including cleaning, pickling, cold rolling, annealing, and coating. These processes remove impurities, improve surface quality, reduce thickness, enhance mechanical properties, and provide corrosion resistance to ensure that the steel coils meet the required specifications for various manufacturing applications.

- Q: How are steel coils used in the production of medical equipment?

- Steel coils are an essential component in the production of medical equipment as they are used to manufacture various parts and components such as surgical instruments, implants, and medical machinery. The high strength and durability of steel make it ideal for creating precise and long-lasting medical devices, ensuring the safety and reliability of the equipment used in the healthcare industry.

- Q: How are steel coils shaped into specific forms?

- Steel coils are shaped into specific forms through a process called cold rolling, where the coils are passed through a series of rollers that apply pressure to gradually shape and form the steel into the desired shape.

- Q: How are steel coils used in the production of steel washers?

- Steel coils are used in the production of steel washers as they are unwound, flattened, and cut into smaller pieces to create the raw material for manufacturing washers.

- Q: I have heard that heating the steel and applying oil will help with corrosion, and will give that aged look. I would like to know finishes available without painting. thanks

- Windex works the suited. makes it seem purely like a mirror. if it quite is dingy their is those products that they sell in supermarkets and motor vehicle automobile areas shops observed as brasso it gets the annoying deposits out.

Send your message to us

Corrugated Sheets /Steel Manufacturer/ /Roofing Application Colour Steel coil/AL-Zn PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords