Coated Surface Treatment Mental steel /Roofing Application Colour Steel coil/AL-Zn PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Coated Surface Treatment Mental steel Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of Coated Surface Treatment Mental steel

.Used as roof panel, wall panel in steel structure in warehouse, factories exhibition hall container houses, cold storage

.It is also mainly used in light industry, automobile, construction, animal husbandry, fishery and commerce, etc,

3.Product Introduction information:

| Product | Coated Surface Treatment Mental steel |

| Base Material | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| Color | All RAL Color,or be customized |

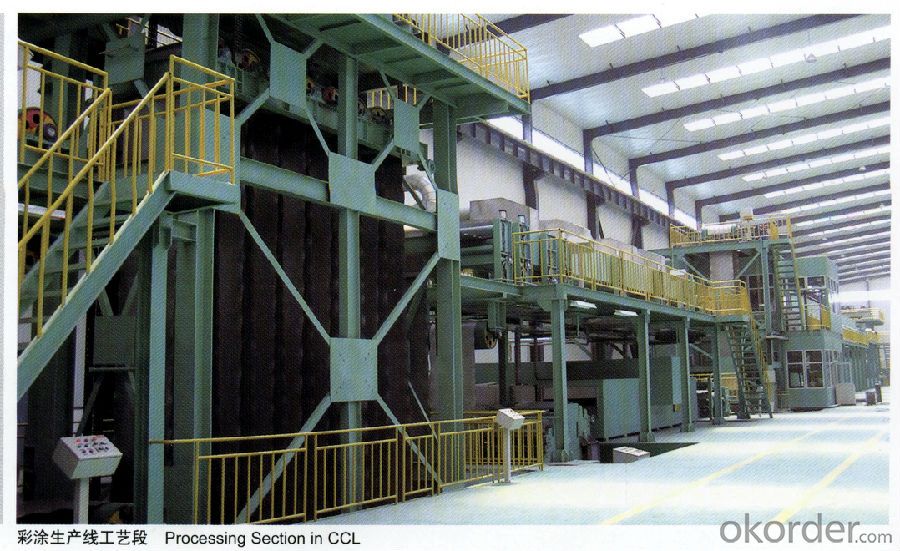

| Equipment | Double coating double baking; three coating three painting |

| Production Capacity | 500,000 Tons per Year |

| Size | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| Zinc Coating | 30g/m2-150g/m2 |

| Thickness | Top Side: 10-25 microns; Back Side: 4-8 microns |

| Coil Weight | Normally 5 Tons per Coil, aslo as required by customer |

| Coil ID | 508mm/610mm |

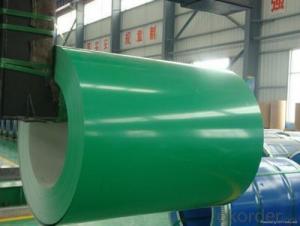

4.Color Coated Galvalume Steel Coil image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel coil surface treatments for indoor applications?

- The different types of steel coil surface treatments for indoor applications include hot-dip galvanizing, electro-galvanizing, and organic coating.

- Q: This question is directed to anyone who has played or know someone who plays a lap or pedal steel guitar.I've been a guitarist for about 8 years now and have played a variety of styles from rock, fingerstyle/classical, singer/songwriter acoustic stuff, ect, and now I've really had an interest in learning how to play a lap steel or pedal steel guitar. I am completely new to the instrument(s), so I'm seeking all the information I can. I do know that a pedal steel is a lot more expensive, so I'm probably looking to start on a lap steel for now. Basically how should I get started? Should I find a cheap lap steel at a pawn shop or purchase something new? Are there any good method books out there? I'm a pretty experienced guitarist, so should I expect to get the hang of it quickly? Is there much of a market for a lap/pedal steel player? haha.Also, I am left handed. How much trouble would it be to re-string a steel guitar? Or would I be better off getting a left-handed model?

- Hello okorder / I'm not familiar with the brand...it's certainly not commonly played....but it has the features you need for a starter guitar.

- Q: What are the challenges faced during steel coil processing?

- There are several challenges that can be encountered during steel coil processing. One of the main challenges is ensuring proper handling of the steel coils. Steel coils are heavy and can weigh several tons, so it is crucial to have the correct equipment and procedures in place to safely move and manipulate the coils. This includes using cranes, forklifts, or other lifting devices that are strong enough to handle the weight and size of the coils. Another challenge is maintaining the integrity of the steel coils during processing. Steel coils are susceptible to damage from scratches, dents, or other forms of physical deformation. It is important to have proper storage and handling procedures in place to minimize the risk of damage. Additionally, care must be taken during cutting, slitting, or other processing operations to ensure that the coils are not damaged or compromised. Quality control is another significant challenge in steel coil processing. It is essential to consistently produce coils that meet the required specifications, such as thickness, width, and surface quality. This requires meticulous inspection and monitoring throughout the entire processing chain, from receiving the raw material to the final product. Any deviations from the desired specifications can result in rejected coils or customer dissatisfaction. Efficiency and productivity are also challenges in steel coil processing. The processing operations need to be optimized to minimize waste, reduce downtime, and maximize throughput. This can involve implementing automation, improving production planning, and streamlining the workflow. Additionally, balancing the production speed with maintaining quality standards is crucial to ensure efficient and productive processing. Lastly, safety is a significant challenge in steel coil processing. The nature of the equipment and processes involved poses various risks to workers, including the potential for accidents, injuries, or exposure to harmful substances. It is vital to have proper safety protocols in place, provide adequate training to employees, and regularly inspect and maintain the equipment to ensure a safe working environment. In summary, the challenges faced during steel coil processing include handling the heavy coils, maintaining their integrity, ensuring quality control, optimizing efficiency and productivity, and ensuring a safe working environment. By addressing these challenges, steel coil processors can achieve smooth operations and deliver high-quality products to their customers.

- Q: where can i get a thick sheet of steel ? and is steel bullet proff for example if you shoot a bullet on steel will that bullet bounce right off the steel ?

- Try the business-to-business yellow pages in your area. A local hardware store can also tell you who to contact. Or search steel plate or sheet metal on the internet to find a local supplier. No, sheet steel is not bullet proof, unless you get heavy plate. Depending on how thick it is, the plate will deform if hit by a high velocity bullet, but usually not enough to matter. Bullets have velocities from about 500 ft/sec up to roughly 3000 ft/sec, depending on the type of weapon used. I wouldn't try to use anything thinner than 3/4 inch. You'll have to experiment and see what it will actually stop. I can't guarantee it'll stop a high-velocity rifle slug. Try it and see.

- Q: The difference between aluminized color steel roll and ordinary color steel roll

- Aluminized color coated sheet is a new type of material produced in China in recent years due to its high end applications. It is often used as an indication of CCLI. It is made of galvanized steel sheet (55% aluminum, 43% zinc and 1.6% silicon), which is more galvanized and more corrosion resistant. It is processed by surface degreasing, phosphating and complexing treatment, and is coated with organic coating.

- Q: How do steel coils impact the overall cost of production?

- The overall cost of production in various industries is greatly affected by steel coils. Initially, the expense of the steel coils themselves can be quite significant. The price of steel is influenced by several factors, including supply and demand, raw material costs, and market fluctuations. Any increase in the price of steel coils can directly impact the overall cost of production, as they are a major component in the manufacturing process. Furthermore, the operational costs of production are also influenced by steel coils. These coils are commonly used in different manufacturing processes, such as stamping, rolling, and forming, which require specialized machinery. The efficiency and effectiveness of these processes greatly depend on the durability, quality, and size of the steel coils. If the coils are of low quality or not suitable for the specific production requirements, it can result in increased downtime, machinery maintenance, and rework, all contributing to higher production costs. Additionally, the transportation costs associated with steel coils can impact the overall cost of production. Steel coils are typically heavy and bulky, requiring special handling and transportation arrangements. The logistics costs can be significantly influenced by factors such as the distance between the supplier and the production facility, as well as the chosen mode of transportation. Any rise in transportation expenses, such as fuel prices or shipping fees, can directly affect the overall cost of production. Lastly, the availability of steel coils can also impact production costs. During periods of high demand or limited supply, the price of steel coils may increase, resulting in higher production costs. Moreover, if there is a shortage of steel coils due to trade restrictions or disruptions in the supply chain, manufacturers may have to resort to alternative materials or sources, which could be more expensive or of lower quality. These factors can have a ripple effect on the overall cost of production. In conclusion, steel coils have a significant impact on the overall cost of production. Their cost, quality, transportation, and availability all influence the efficiency, effectiveness, and affordability of the manufacturing process. Therefore, manufacturers must carefully consider and manage these factors to optimize their production costs and maintain competitiveness in their respective industries.

- Q: How are steel coils cleaned?

- Steel coils are typically cleaned using a combination of processes such as chemical cleaning, mechanical cleaning, and/or high-pressure water blasting. The specific method used depends on the type and extent of dirt or contaminants present on the coils. Chemical cleaning involves applying specialized cleaning agents to dissolve and remove dirt, oil, or other substances. Mechanical cleaning may involve scrubbing or brushing the coils to physically remove debris. High-pressure water blasting is often employed to remove tough residues or surface impurities. The cleaning process aims to ensure that the steel coils are free from any contaminants before further processing or usage.

- Q: Can anyone suggest a free font that looks like steel with rivets? I'm looking for something industrial looking.

- Steel Font

- Q: What are the environmental impacts of steel coil production?

- The environmental impacts of steel coil production include emissions of greenhouse gases, such as carbon dioxide, during the process of extracting and processing raw materials like iron ore and coal. Additionally, the production of steel coils requires a significant amount of energy, contributing to the depletion of natural resources and increased carbon emissions. The wastewater generated during steel production can also contain pollutants, which may harm aquatic ecosystems if not properly treated. Furthermore, the disposal of steel coil waste, such as slag and other by-products, can pose challenges in terms of proper handling and potential contamination of soil and water sources. Overall, steel coil production has substantial environmental impacts that demand sustainable practices and mitigation measures.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

Send your message to us

Coated Surface Treatment Mental steel /Roofing Application Colour Steel coil/AL-Zn PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords