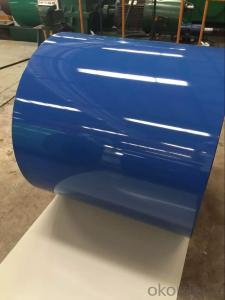

PPGI/Color Coated Steel for Roofing/Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

From China Manufacturer PPGI/PPGL Prepainted Galvanized Steel For Building Steel Material / Roofing

1) Price terms: CIF CFR FOB

2) Payment: T/T or L/C at sight

3) Shipping port: Qingdao China

4) Samples are available and free of charge

5) Coil ID : 508 / 610 MM

6) Packing: seaworthy packing

7) Delivery: about 10-15 days upon the day of deposit and L/C opening

Product | PPGI/PPGL | Galvanized | Galvalume/Aluzinc | |

Certificate | ISO9001:2008,ISO14001:2004 | |||

standard | ASTM A755 | ASTM A653 | ASTM A792 | |

Grade | CGCC/CGLCC | SGCC/CS/DX51D | SGLCC/CS/DX51D | |

Model | Thick:0.16-0.90mm | Thick:0.14-3.5mm | Thick:0.23-2.0mm | |

Type | Roll/Coil | Roll/Coil | Roll/Coil | |

surface | Protective | Chromating Treatment Oiled | ||

Application | Structural,Roofing,Commercial use,Household Appliance,Industry | |||

Special | Wear resistant steel,High-strength-steel plate | |||

FAQ

1. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: What is the tensile strength of steel coils?

- The tensile strength of steel coils varies depending on the specific grade and composition of the steel. However, on average, steel coils have a tensile strength ranging from 400 to 600 megapascals (MPa).

- Q: How are steel coils used in the production of steel nails?

- Steel coils are used in the production of steel nails by being fed into a nail-making machine, where they are unwound and cut into the desired length. The coils provide a continuous supply of steel material, allowing for efficient and automated nail production processes.

- Q: This is my first time buying new strings for my violin and I’ve narrowed it down to two choice based on reviews and cost. The only difference I can see between the strings is that one has a solid steel core and the other has a synthetic core. What are the pros and cons of each type of core?

- Steel okorder /

- Q: What is galvanized steel coil?

- Galvanized steel coil is a type of steel that has been coated with a layer of zinc to protect it from corrosion. The process of galvanization involves immersing the steel coil in a bath of molten zinc, which forms a protective layer on the surface of the steel. This layer not only prevents corrosion but also provides a barrier against scratches and other damage. Galvanized steel coil is commonly used in various industries, including construction, automotive, and manufacturing, due to its durability and resistance to rust. It is often used for making roofing materials, pipes, and automotive parts, among other applications. Overall, galvanized steel coil is a versatile and cost-effective solution for ensuring the longevity and integrity of steel products.

- Q: Or is it a coating that is applied? If so what types of steel? Or what types of coatings?

- there is a weathering steel that corrodes and then stops. The outer surface of the steel is a rusty looking brown but after the first layer of rust appears, the process stops. It used to be called A588 steel. So called mild steel is not A36 anymore, it is A992 (50 ksi yield). The only material that is A36 anymore are angles, channels, and plate. You can coat the steel with an epoxy coating to protect the steel from this highly corrosive environment. Google a company called TNEMEC. They offer epoxy coatings for steel and other coatings. Weathering steel and epoxy coating are not cheap options.

- Q: How would you calculate the maximum plastic deformation (expansion) a steel pipe can handle before it actually fails?

- You can calculate the maximum reversible strain, for elastic loading as follows: You need to look up the yield strength (for that particular type of steel). Divide this yield strength by the elastic modulus of steel (also called Young's modulus). That gives you the strain at the onset of yielding, the maximum you can strain the steel fibers before crossing the point of no return. If you are interested in the strain until failure, you need to take tensile test measurements. Seldom do people document an equation to model the non-elastic portion of the stress-strain curve of the specimen, because seldom do we design systems to operate with materials which yield. We want systems which only deform reversibly and elastically. This means you need to perform an experiment to find what you are actually desiring to know.

- Q: How are steel coils stored in warehouses?

- Steel coils are typically stored in warehouses by stacking them securely on top of each other, either directly on the warehouse floor or on specially designed racks. They are often stored vertically to save space and ensure stability. Additionally, to prevent damage and corrosion, steel coils are often wrapped in protective materials or placed on pallets.

- Q: what are the characteristics when of iron or steel when stretched? which one could be stretched further? which one stretches more evenly?thankyou

- Technically, this is known as ductility. a material which can be permanently bent and stretched is said to be ductile. Pure iron, when it lacks carbon and impurities like sulfur and phosphorus, is relatively soft, ductile, and weak. It's about as soft as brass. It can be stretched to about 50% of it's original length before it breaks. The amount a sample can be stretched without breaking is known as elongation. The key to steel is the addition of about 2 parts per thousand of carbon, or around 0.2%. This alters the crystal structure and makes steel much harder, stronger, and tougher, though it also becomes somewhat less ductile. Mild steel, with a low carbon content, has an elongation of around 30% Adding more carbon makes the steel yet stronger, but further reduces the elongation. Adding more than 2-3% carbon produces what is known as Cast Iron. Cast iron is brittle. It has virtually no ductility. It's pretty cheap to produce though.

- Q: I have the game of the year edition for fallout 3 but there's no mission or quest saying it's called broken steel so what is it actually called and where is it? Please describe the quest in case I mightve already done it without even knowing.

- If I can remember right (SPOILER) you have to beat the game and instead of dying you just pass out and wake up with the brother hood of steel.

- Q: How are steel coils used in the manufacturing of doors and windows?

- Steel coils are used in the manufacturing of doors and windows as they provide the necessary strength and durability required for these products. The coils are first processed and shaped into the desired form, which is then used as the base material for constructing the frames and panels of doors and windows. The steel coils also undergo various treatments, such as galvanization or coating, to enhance their resistance to corrosion and weathering. Overall, steel coils play a crucial role in ensuring the structural integrity and longevity of doors and windows.

Send your message to us

PPGI/Color Coated Steel for Roofing/Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords