Color Coated Steel Coils Pre-painted Aluzinc Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Color Coated Steel Coils Pre-painted Aluzinc Steel Coils:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage,they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

2.Features of Color Coated Steel Coils Pre-painted Aluzinc Steel Coils:

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc.

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

3.Details of Color Coated Steel Coils Pre-painted Aluzinc Steel Coils:

Size | (0.13mm-5.0mm )*(600mm-1500mm)*coil |

Steel Grade | JIS G3302 SGCC~SGC570,SGCH(FULL HARD-G550),SGHC~SGH540 EN 10346-DX51D+Z,DX53D+Z, S250GD~S550GD ASTM A653M CS-B, SS255~SS550 |

Coil Weight | 3MT-14MT |

Coil ID | 508mm/610mm |

Chemical Treatment | Chromated(Cr 3+,6+,0+) |

Surface | Skin pass/non skin pass |

Oil | Slight Oiled/Dry |

Spangle | Regular/Zero/Big |

Zinc Coating | Z40-Z300 |

Capacity | 1,500,000MT/year |

Mill Origin | HBIS-Tangsteel,Shandong Zhongguan, Changshu Everbright, WISCO |

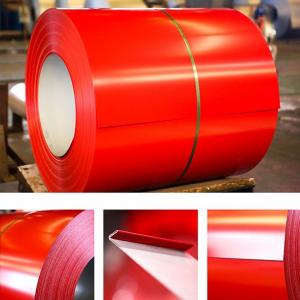

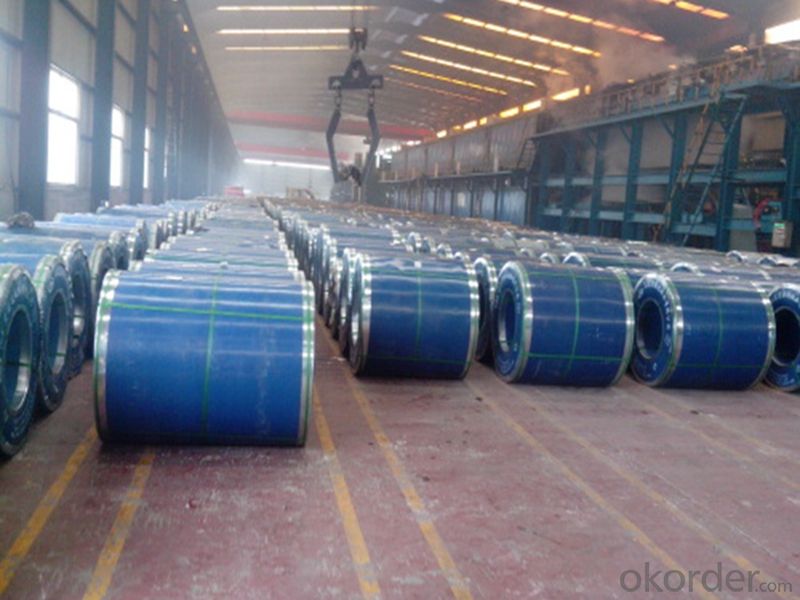

4.Color Coated Steel Coils Pre-painted Aluzinc Steel Coils image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- The length of the roll is related to its width and thickness, but not to the extent of the zinc layer.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: How are steel coils affected by global trade policies?

- Steel coils can be significantly affected by global trade policies. Trade policies, such as tariffs and quotas, can impact the import and export of steel coils, influencing their availability and pricing in different markets. Changes in trade policies can lead to shifts in supply and demand, affecting the volume and cost of steel coil imports and exports. Additionally, trade policies aimed at protecting domestic industries may create barriers for steel coil imports, potentially affecting the competitiveness of steel coil manufacturers and suppliers.

- Q: What minerals are mixed to make steel?

- Carbon and Iron.....usually.

- Q: What are the advantages of using galvanized steel coils?

- There are several advantages to using galvanized steel coils. Firstly, galvanized steel is highly resistant to corrosion, which means it can withstand exposure to moisture and other harsh environmental conditions without rusting. This makes it a durable and long-lasting material for various applications. Secondly, galvanized steel coils have a protective zinc coating that acts as a barrier against damage and provides excellent structural strength. Additionally, galvanized steel coils are versatile and can be easily formed, welded, and painted, making them suitable for a wide range of industries and projects.

- Q: How do steel coils contribute to the manufacturing of household appliances?

- Steel coils are an integral component in the manufacturing of household appliances. These coils, made from high-quality steel, play a crucial role in providing the necessary strength and durability required for the production of various appliances. One of the primary uses of steel coils in household appliances is in the construction of the appliance's body or frame. The coils are shaped and formed into the desired structure, providing a sturdy foundation for the appliance. This ensures that the appliance can withstand the rigors of everyday use and remain intact for an extended period. Moreover, steel coils are also used in the manufacturing of various components within household appliances. For example, in refrigerators and air conditioners, steel coils are utilized in the condenser and evaporator coils, which are responsible for the heat exchange process. These coils allow for efficient cooling or heating, ensuring optimal performance of the appliance. Furthermore, steel coils are also employed in the production of appliance interiors, such as oven racks, dishwasher baskets, and laundry machine drums. The strength and resistance provided by the steel coils help these components withstand heavy loads and repeated use, enhancing the overall longevity and reliability of the appliance. Additionally, steel coils contribute to the aesthetic appeal of household appliances. They can be shaped, molded, and coated to achieve various finishes, colors, and textures, enhancing the visual appeal of the appliance and making it more attractive to consumers. In summary, steel coils are crucial to the manufacturing of household appliances as they provide strength, durability, and resilience to the appliance's structure, components, and interiors. They play a vital role in ensuring the performance, reliability, and longevity of these appliances, making them an indispensable part of the manufacturing process.

- Q: How are steel coils used in the production of HVAC ducts?

- HVAC duct production relies heavily on steel coils, which are vital for their construction. These coils, typically composed of galvanized steel, possess the qualities of strength, durability, and corrosion resistance. To create the necessary flat sheets, the steel coils undergo an initial unwinding and flattening process. These sheets are then cut into specific sizes and shapes in accordance with the design and dimensions of the HVAC ducts. Additionally, the steel coils are subjected to various machines, such as shearing, slitting, and roll forming machines, to achieve the desired shapes and sizes for the ducts. Once transformed into the appropriate shapes, the steel coils are further processed to add additional features to the ducts. This can include bending, folding, or welding processes to create bends, angles, or connections in the ductwork. These processes allow for customization, ensuring that the ducts perfectly fit the specific requirements of the HVAC system and the building structure. Moreover, steel coils play a crucial role in maintaining the strength and integrity of HVAC ducts. The galvanized steel used in the coils provides a protective layer that prevents rust and corrosion, resulting in more durable and long-lasting ducts. This is particularly significant as HVAC ducts are regularly exposed to various environmental factors such as moisture, temperature changes, and airborne contaminants. In summary, steel coils are an essential and fundamental component in the production of HVAC ducts. They not only provide the necessary strength, durability, and corrosion resistance but also offer flexibility and customization in the manufacturing process.

- Q: What are the different types of steel coil cutting machines?

- There are several different types of steel coil cutting machines available in the market, each designed to cater to specific needs and requirements. Some of the commonly used types include: 1. Slitting Machines: Slitting machines are used to cut steel coils into narrower strips. They have multiple circular blades that make precise cuts along the length of the coil, allowing for the production of narrower coils or strips. 2. Cut-to-Length Machines: Cut-to-length machines are designed to cut steel coils into specific lengths. These machines can accurately measure and cut the coil to the desired length, ensuring uniformity and precision. 3. Rotary Shears: Rotary shears are heavy-duty cutting machines that can handle thicker and larger steel coils. They use a rotating blade to cut through the coil, making it suitable for cutting thicker gauge materials. 4. Multi-Blanking Machines: Multi-blanking machines are designed to cut steel coils into multiple smaller blanks simultaneously. These machines can cut the coil into various shapes and sizes, making them ideal for producing multiple parts from a single coil. 5. Slit and Cut-to-Length Combination Machines: These machines combine the functionalities of slitting and cut-to-length machines, allowing for both narrow strip cutting and length cutting in a single process. They are versatile and efficient, saving time and increasing productivity. Each type of steel coil cutting machine has its own advantages and is suitable for specific applications. The choice of machine depends on factors such as coil thickness, desired strip width, required length accuracy, and production volume.

- Q: How are steel coils used in the production of automotive body panels?

- Steel coils are used in the production of automotive body panels by being fed into a stamping press, where the coils are shaped and cut into the desired panel shapes. The high strength and durability of steel make it an ideal material for automotive body panels, providing protection and structural integrity to the vehicle.

- Q: What are the different methods of roll forming steel coils?

- There are several different methods of roll forming steel coils, including hot rolling, cold rolling, and continuous casting. Hot rolling involves heating the steel above its recrystallization temperature and then passing it through a series of rollers to shape it into the desired form. Cold rolling, on the other hand, is performed at room temperature and involves passing the steel through rollers to increase its strength and improve surface finish. Continuous casting is a method where molten steel is continuously poured into a mold and then cooled to form a solidified strip or slab. These methods offer different advantages and are used in various applications based on the desired properties of the steel product.

Send your message to us

Color Coated Steel Coils Pre-painted Aluzinc Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords