Color Coated Galvanized Steel Coil PPGI in Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

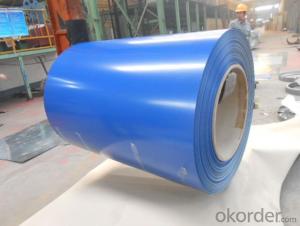

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is the product of mild steel environmentally friendly? does it produce any emissions?The same question for leather aswell.

- Steel just rusts, it doesn't produce any emissions just sitting there. They even make architectural steel called Corten to rust to a nice patina. If you consider how the steel was made in the first place, a great big NO! Steel making requires massive amounts of electricity plus it gives off some nasty fumes in the liquid state. Leather itself doesn't emit much of anything, but the dyes might. Again though, if you look at how it's made, tanning leather is right up there with steel mills and paper mills for pollution, some of the worst.

- Q: What are the dimensions of steel coils used in the storage system industry?

- The dimensions of steel coils used in the storage system industry can vary depending on the specific requirements and applications. However, there are some common dimensions that are widely used. The most common coil width ranges from 600mm to 2000mm, although it can be as narrow as 100mm or as wide as 2500mm in certain cases. The coil thickness typically ranges from 0.5mm to 6mm, but it can go up to 25mm for specialized applications. The inner diameter of the coil, known as the core diameter, is usually between 508mm and 610mm. The weight of steel coils can vary significantly depending on the width, thickness, and length of the coil. However, a standard steel coil can weigh anywhere from 3 to 20 tons. It is important to note that these dimensions are not fixed and can be customized based on the specific storage system requirements and the industry in which they are used.

- Q: How are steel coils processed for further use?

- Steel coils are processed for further use through a series of steps that include uncoiling, leveling, cutting, and sometimes additional treatments such as galvanizing or painting. These processes ensure that the steel coils are prepared and ready to be used in various industries such as automotive, construction, or manufacturing.

- Q: Hello... I'd like to know where I can find proof of this answer as well please. My own searching didn't come up with anything concrete.I'd like to know how much the ambient temperature inside of a hollow steel tube would rise by if the outside of that tube was exposed to an 1100 degree flame for a period of 3 seconds.If specifics help, they are something along the lines of 3.125 O.D. tube, 0.35 wall thickness. High grade steel, can't be more specific than that sorry.Thanks for any answers!

- yes it is very possible. as what our teacher in physics said that steel is a good conductor of heat..

- Q: How are steel coils used in the production of wire products?

- Wire products rely heavily on steel coils, which are indispensable in their production. These coils, typically crafted from high-quality steel, serve as raw materials in wire drawing processes. Wire drawing, a manufacturing technique, diminishes the coil's diameter, converting it into diverse wire products. The initial step involves the placement of a steel coil onto a wire drawing machine. Subsequently, the machine pulls the coil through a sequence of progressively smaller dies. Each die the coil passes through reduces the wire's diameter, resulting in a more slender and elongated wire strand. This process can be repeated multiple times until the desired wire thickness is achieved. Once the wire is drawn, it can undergo further processing to create an array of wire products, including fencing, nails, screws, springs, and electrical wires. The wire can be cut into specific lengths, bent, or shaped to suit its intended purpose. Moreover, it can undergo treatments like galvanizing or coating to enhance its durability and resistance to corrosion. Steel coils offer numerous advantages in wire product manufacturing. Firstly, they provide a consistent and uniform material, ensuring the resulting wire products possess consistent quality and performance. Secondly, steel coils are easily transportable and can be stored efficiently, making them a cost-effective choice for manufacturers. Lastly, the versatility of steel enables the production of wire products with varying tensile strengths and properties to meet specific industry requirements. To summarize, steel coils play an essential role in wire product manufacturing. They serve as the primary raw material in wire drawing processes, where they undergo a series of reduction steps to be transformed into diverse wire products. These wire products find applications across various industries, solidifying the indispensability of steel coils in the manufacturing sector.

- Q: Hey I just got a mini 14 manufactured in 1980. I also had some .223 Wolf steel cased HP rounds (about 200) that i could shoot throught it, but I was just wondering if its a bad idea to use this steel cased ammo...? Only the casing is steel i believe... and the bullet is copper jacketedthanks for your help

- I have used wolf steel cased ammunition as well when I borrowed my friend's AR-15. It's good ammunition and I personally have not experienced a stovepipe or a jam with the ammunition. A Mini 14 is a great .223 civilian rifle made by Ruger and should not jam with the ammunition. If the polymer coating really is a problem sometimes, just don't use it with knockoff AR-15s or Mini-14s but stick with the major manufacturers.

- Q: What are the common coil edge finishes?

- The common coil edge finishes include slit edge, mill edge, and deburred edge.

- Q: How do steel coils contribute to the packaging industry?

- Steel coils play a crucial role in the packaging industry by providing a durable and versatile material for packaging various products. The use of steel coils in packaging ensures the protection and preservation of goods during transportation and storage. One way steel coils contribute to the packaging industry is through their strength and durability. Steel is known for its high strength-to-weight ratio, making it an ideal material for packaging heavy and bulky items. Steel coils can withstand significant pressure and impact, ensuring that goods remain intact and undamaged throughout the supply chain. This strength also allows for the stacking of packages, optimizing storage space and reducing the risk of damage. Furthermore, steel coils are highly resistant to corrosion and moisture. This property is particularly important in the packaging industry as it helps protect goods from environmental factors that could potentially compromise their quality. Steel coils can be coated or treated to enhance their corrosion resistance, ensuring that packaged products remain in pristine condition. Steel coils are also versatile and can be easily customized to suit specific packaging requirements. They can be cut and shaped into various forms, such as sheets, straps, or bands, to secure and protect different types of products. Additionally, steel coils can be easily integrated with other packaging materials, such as cardboard or plastic, to provide added strength and stability. Another benefit of steel coils in the packaging industry is their recyclability. Steel is one of the most recycled materials globally, and steel coils can be easily recycled and reused. This sustainability aspect makes steel coils an environmentally friendly choice for packaging, contributing to the reduction of waste and the conservation of resources. In summary, steel coils play a vital role in the packaging industry by offering strength, durability, corrosion resistance, versatility, and recyclability. Their use ensures the safe transport and storage of goods, providing a reliable and sustainable packaging solution for a wide range of industries.

- Q: How are steel coils used in the production of consumer goods?

- Steel coils are used in the production of consumer goods as raw materials for various manufacturing processes. They are often shaped, cut, or formed into different components and parts that go into products such as appliances, automobiles, furniture, and construction materials. Steel coils provide strength, durability, and versatility, making them essential in creating high-quality consumer goods.

- Q: How are steel coils used in the manufacturing of railway equipment?

- The strength, durability, and versatility of steel coils are crucial factors in their importance in the manufacturing of railway equipment. These coils, typically made from high-quality steel, are extensively used in various applications throughout the railway industry. A primary application of steel coils in the manufacturing of railway equipment is the production of train tracks. By rolling and shaping steel coils into long, continuous rails, the foundation of railway tracks is formed. This allows the tracks to withstand heavy loads, constant train traffic, and harsh weather conditions, thanks to the coils' strength and durability. Moreover, the uniformity and consistency of steel coils ensure smooth and safe train operations. Additionally, steel coils are utilized in the manufacturing of railway wagons and carriages. These coils are shaped into various components, such as the framework, body panels, and structural supports of the wagons. The robustness of steel coils guarantees the structural integrity of the wagons, enabling them to carry heavy cargo and endure the hardships of railway transportation. Furthermore, steel coils find use in the fabrication of various railway equipment accessories, including couplings, brake systems, and suspension components. These coils are shaped and sized precisely to meet the specific requirements of each accessory. The strength and resilience of steel coils make them ideal for these critical parts, ensuring the efficient and safe operation of railway equipment. In conclusion, the role of steel coils in the manufacturing of railway equipment is vital. Their strength, durability, and versatility make them an essential material for constructing train tracks, wagons, carriages, and various accessories. The use of steel coils guarantees the safety, reliability, and longevity of railway equipment, making them an integral part of the railway industry.

Send your message to us

Color Coated Galvanized Steel Coil PPGI in Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords