PPGI,Pre-Painted Steel Coil in High Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

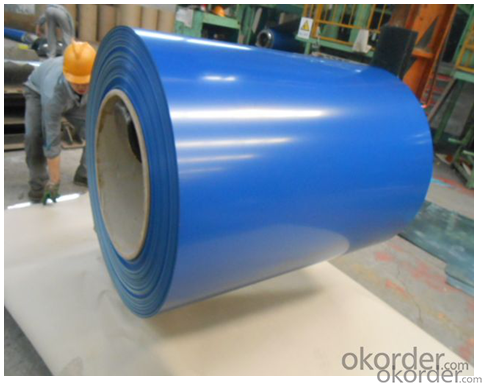

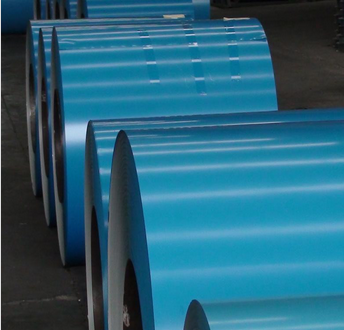

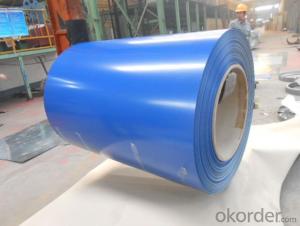

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Why can hot rolled coils be placed outside?

- Because the stress of participation should be eliminated

- Q: I am in the US and looking for a price on wide flange steel. I need a price of one W10x30 and 20 feet long.

- The price of steel is increasing daily, so an exact answer is rough. A W10x30 is a fairly common shape and shouldn't be too hard to find. For a very rough ballpark number, say $700/ton (installed price), the piece you require should be in the range of about $250.00 or less as I assume you'll be doing the installing. Please don't take this as the gospel, however. Price varies on location, stock, and availability. Open the phone book and contact your local steel supplier. Because the piece you require is fairly short, you might get lucky and find someone who has a waste piece that length that they will give you a good deal on. --------------------------------------... I just checked the AISC web site to verify the number I quoted above and they posted an article stating that the average mill price had just increased to over $1000/ton in May. The best advice I can provide at this point is to buy the W10 now and don't wait any longer.

- Q: What are the common coil grades available for steel coils?

- The common coil grades available for steel coils are typically classified into three main categories: low carbon steel, medium carbon steel, and high carbon steel.

- Q: How are steel coils made?

- Steel coils are made through a process called hot rolling, where a large slab of steel is heated and passed through a series of rolling mills to gradually reduce its thickness and shape it into a coil.

- Q: How are steel coils used in the petrochemical industry?

- Steel coils are commonly used in the petrochemical industry for various purposes such as manufacturing pipes, tanks, and equipment used in the processing and transportation of petrochemical products. The coils are typically formed into specific shapes and sizes to meet the industry's requirements, ensuring structural integrity and resistance to corrosion. These steel components play a critical role in maintaining the safety and efficiency of petrochemical operations.

- Q: What does "steel roll number" mean?

- Steel coil number is the specification of steel coil.

- Q: I mean 4 inch thick steel like was used in the WTC buildings, especially WTC 7 which did not get hit by a plane. Can carpeting, desk chairs, water coolers and dry erase boards burn hot enough and long enough to melt steel that is normally made in a blast furnace?

- A fire doesn't have to melt steel to do damage. Merely softening the steel makes it weaker and easier to bend. Structural collapse can then occur at temperatures far lower than melting temps. Ask yourself why does a blacksmith heat steel to work and bend it?

- Q: Why can't you use a lead shot only choke with steel shot or a steel shot only choke with lead shot? I have used a lead only choke with steel shot and my shotgun shot fine and there was no damage to the choke.

- The reasoning behind lead shot only is that those chokes (usually) have a very tight constriction. It can cause severe and dangerous pressure spikes when a charge of steel shot (almost impossible to compress compared to lead) gets slammed through them. Another reason could be that the tubes are either very soft steel or very thin and steel shot will damage them quickly. I personally haven't seen any steel shot ONLY tubes before just ones marked for lead and/or steel or ok for steel shot.

- Q: How are steel coils used in the production of structural components?

- Steel coils are an integral part of the production process for structural components. These coils, which are made of steel that has been rolled into a continuous strip, provide the raw material necessary for manufacturing a variety of structural components, such as beams, columns, and trusses. The first step in using steel coils for structural components involves uncoiling the strip and cutting it into the desired lengths. This can be done using a variety of cutting methods, such as shearing or sawing. Once the coils are cut into lengths, they are then processed further to shape them into the specific structural components needed for a particular project. One common method used to shape steel coils into structural components is through the process of bending or forming. This involves using specialized machinery to bend or shape the steel into the desired configuration. For example, a steel coil can be bent into an I-beam shape, which is commonly used as a load-bearing structural component in buildings and bridges. Another method used to shape steel coils into structural components is through the process of welding. This involves joining multiple steel coils together to create a larger component. Welding is often used to fabricate components such as columns or trusses, which require the combination of multiple steel coils to achieve the necessary strength and structural integrity. Once the steel coils have been shaped and formed into the desired structural components, they may undergo additional processes, such as surface treatment or coating, to enhance their durability and resistance to corrosion. This ensures that the components will have a long lifespan and can withstand the demands of their intended applications. In summary, steel coils are essential in the production of structural components as they provide the raw material necessary for manufacturing. Through processes such as cutting, bending, and welding, steel coils are shaped into the specific components needed for various construction projects. These components play a crucial role in supporting the structural integrity of buildings, bridges, and other structures.

- Q: My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- Reinforced Steel is found in concrete, and if the towers were built with reinforced concrete (concrete beams with rebar) then they would likely still be standing. The twin towers were made of steel. When steel is heated up, it deforms and collapses, which is why it didnt stand up. One of the top 2 things against steel is that it is not fire resistant.

Send your message to us

PPGI,Pre-Painted Steel Coil in High Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords