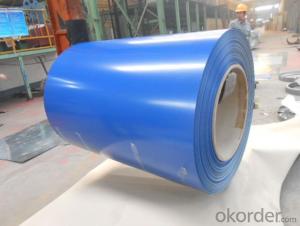

PPGI Color Coated Galvanized Steel Coil Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I'm getting new strings on my dad's old acoustic guitar so I can learn how to play it and I'm wondering if I should get nylon or steel strings. Are there any major differences between the two aside from the nylon strings being easier on your fingers? Like do the Nylon strings sound different?

- Listen to jwent You do NOT want to put steel strings on a nylon string guitar it will pull up the bridge, and top of the guitar, and break the plastic tuners that can't handle the extra tension You can put nylon a steel string guitar, but it won't sound like a classic guitar, because the steel string guitar has the extra bracing, to handle the tension of the steel strings, won't hurt anything, just won't sound as good If you want to soften the feel and sound of a steel string guitar, another option is silk n steel

- Q: Can a steel at 0.0055 of thickness still be powerful enough to bash skulls? As well as stop handgun cartridges or at least weaken them?You see, i had an idea of making a cylindrical Knuckles made from steel. By my dimensions, 5in diameter, 12 inch h1 and 15 in h2. Half-Sphere: a sphere that is cut in half for the dome at the fist:( [ pi x ( d ^ 3) ] / 6 ) / 2Cylinder

- I don't follow your calculations. It seems to me that the piece you show could be made from .01 steel and still be less than a pound. Also, it is hard to get steel thinner than .015 because anything thinner is not very useful. If you made it out of .015 steel and used a high strength steel, it might be useful. You wouldn't be bashing any skulls, but with some spikes on the end, it could do some damage, and protect against knives or other hand weapons. You also won't get any bullet resistance out of anything that thin. If you want to bash skulls and deflect bullets, you have to get up to at least .10 and several pounds. Any weight on your hands slows down the speed of your punch, but this is compensated for by the increased energy of impact carried by the extra mass. Also, having something hard to protect your hands allows for harder hits and more damage to the opponent. An interesting idea, but it would take some testing to figure out the optimum configuration. One problem I see is that it completely encloses the hand, making it impossible to use the hand for anything else. So you would have to put it on and take it off a lot, and there would be cases where you wouldn't be able to put it on when you needed it. For that reason, I would not wear two at one time. I would make it heavier and wear it on one hand for bashing skulls and deflecting weapons, and keep the other hand free for other things.

- Q: What is the yield strength of steel coils?

- The yield strength of steel coils can vary depending on the specific grade and composition of the steel. However, the typical yield strength of steel coils ranges from 300 to 600 megapascals (MPa).

- Q: I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Sounds like the abrasive surface got blinded, coated with something that prevented the abrasive particles from touching the steel. It is possible to have vastly different hardnesses in a single piece of steel. Case hardening, carburizing, induction hardening, heat affected zone from welding, differences in work hardening, and presence of inclusions are some of the things that can create hardness variation within a single piece. But... sounds like you are working with a sheet which is unlikely to have any of these conditions. So... it was probably the grinding disk

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry.

- Q: How do steel coils contribute to the manufacturing of appliances?

- Steel coils are used in the manufacturing of appliances as they serve as a primary raw material for various components such as frames, panels, and structures. These coils are processed and shaped into different forms to meet the specific requirements of different appliances. Additionally, steel coils provide durability, strength, and corrosion resistance to appliances, ensuring their long lifespan and high-quality performance.

- Q: I heard that the stores don't sale Steel Legion anymore...Is this true..Also I want to know why they cost more than regular Imperial Guardsmen..Such as Cadian...Do they have something Special?Also what do I need to buy to have a complete Steel Legion army..I need two squads of troops of 20's?and two sergeants for each squad.and one commiser?Well I;m guessing..someone please help...I havent played in about 4 years.

- The stock at various shops may vary, but you can buy Steel Legion miniatures through the mail order, or the Internet from GW. Cadian troopers are plastic, There are no plastic Steel Legion troops. The plastic models are (a tiny bit) not so horribly expensive as the metallic ones. The minimum requirements for your force vary from mission to mission, but a good start is 1 HQ unit 2 Troop choices. Also, the total points cost of the battle is to be considered. (Usually 500, 1000, or 1500 points.) What you described is one possible choice, although the size of IG squads is 10 and not 20. And you must include a command squad, the commissar is optional. You might change the other 20 troops for a tank, or a squad of Sentinels. Happy gaming!

- Q: What could the impurities in steel wool be?And why are they there?Thanks for your help :)

- Impurities in steel wool would be of the elemental type. I'm sure steel wool is a mixture of different low grade not good for much of anything else materials. There may be excessive impurities such as lead, cobalt, boron, aluminum etc... in the steel wool. There may also be solvent residue on the wool i.e cleaner, lubricant etc.. I'm sure every batch is different - I know the iron level is high thats what makes them rust quickly.

- Q: How are steel coils used in the manufacturing of wind turbines?

- Steel coils are used in the manufacturing of wind turbines for various purposes, including the fabrication of tower structures, rotor blades, and other components. The steel coils are typically processed and shaped into specific forms, such as rolled sections for tower construction or sheets for blade manufacturing. These coils provide the necessary strength, durability, and structural integrity required for the efficient and reliable operation of wind turbines.

- Q: What are the common uses of cold rolled steel coils?

- Cold rolled steel coils are commonly used in a variety of industries and applications. Some of the common uses include manufacturing automotive parts, appliances, construction materials, and electrical components. The cold rolling process provides the steel with a smoother surface finish, improved strength, and better dimensional accuracy, making it suitable for various manufacturing purposes.

Send your message to us

PPGI Color Coated Galvanized Steel Coil Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords