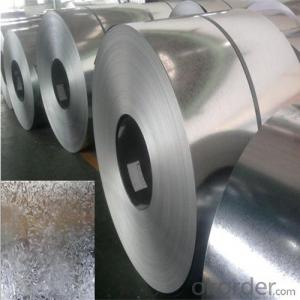

THE BEST HOT-DIP GALVANIZED STEEL COILS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details |

|

|

|

|

|

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | Brand Name: | N/M | Model Number: | ssp-226 | |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet |

|

|

Packaging & Delivery |

|

|

|

|

|

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.PackagingDetails:

Standardexport package.

Othertypes of packing can be customized as per client's requirements.

- Q: i'm looking into pedal steel guitars, and I would like some suggestions or links and info on what kind i should get.

- Try okorder -The Art of Steel Guitar/ Steel guitar players -Take it away Leon- McAuliffe and 'Speedy West' were a couple greats. In the late '50s, Speedy was playing a Fender 1000 Pedal steel. He often did duets with Jimmy Bryant The Fastest Guitar Player In The Country! / note also the 'Emmons Guitar Company':

- Q: How are steel coils processed and shaped into specific products?

- Steel coils are processed and shaped into specific products through a series of manufacturing steps. Initially, the coils are uncoiled and straightened to remove any bends or twists. Then, the steel is cut into desired lengths using shearing or slitting techniques. Next, the cut steel is shaped and formed through processes like rolling, bending, or stamping to achieve the desired shape. Additional operations such as welding, machining, or surface treatments may also be performed. Lastly, the finished products are inspected for quality and packaged for distribution.

- Q: What are the different types of steel coil grades and specifications?

- There are several different types of steel coil grades and specifications, including hot rolled, cold rolled, galvanized, and stainless steel coils. Each type has its own unique properties and uses. Hot rolled coils are produced at high temperatures and are commonly used in construction and manufacturing applications. Cold rolled coils are produced at lower temperatures and have a smoother finish, making them suitable for applications that require a higher level of precision. Galvanized coils are coated with a layer of zinc to protect against corrosion, while stainless steel coils contain a high percentage of chromium for added durability and resistance to corrosion. Overall, the choice of steel coil grade and specification depends on the specific requirements of the project or application.

- Q: What are the common methods of protecting steel coils from corrosion?

- There are several common methods used to protect steel coils from corrosion. 1. Coating: One of the most effective methods is to apply a protective coating on the surface of the steel coil. Various types of coatings such as paint, epoxy, or zinc can be used to create a barrier between the steel and the corrosive environment. These coatings provide excellent corrosion resistance and prevent moisture and oxygen from reaching the steel surface. 2. Hot-dip galvanizing: This method involves immersing the steel coil in a bath of molten zinc, which creates a thick layer of zinc coating on the surface. The zinc coating acts as a sacrificial barrier, protecting the steel from corrosion. Hot-dip galvanizing is particularly effective in harsh environments or for long-term outdoor exposure. 3. VCI (Volatile Corrosion Inhibitor) packaging: VCI packaging is a method where steel coils are wrapped in a specially designed film or paper that contains volatile corrosion inhibitors. These inhibitors vaporize and form a protective layer on the surface of the steel, preventing corrosion. VCI packaging is commonly used for short-term storage or transportation of steel coils. 4. Desiccants: Moisture is a major contributor to corrosion. Therefore, using desiccants such as silica gel or activated alumina can help absorb moisture and maintain a dry environment around the steel coils. Desiccants are often used in conjunction with other protective methods to enhance corrosion protection. 5. Proper handling and storage: Proper handling and storage practices can significantly reduce the risk of corrosion. Steel coils should be stored in a dry environment away from moisture sources. They should also be handled with clean gloves to prevent the transfer of corrosive contaminants. Regular inspection and maintenance of the storage area are essential to identify and address any potential corrosion risks. By employing one or a combination of these methods, steel coils can be effectively protected from corrosion, ensuring their durability and integrity.

- Q: What is the type of stainless steel used in knifes.

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

- Q: What are the common coil loading and unloading techniques?

- Some common coil loading and unloading techniques include using cranes or forklifts to lift and place the coils onto trucks or storage racks, using coil cars or transfer cars to move the coils within a facility, and using coil handling equipment such as coil grabs or C-hooks to safely grip and manipulate the coils during the loading and unloading process.

- Q: What are the common coil inspection techniques?

- Common coil inspection techniques include visual inspection, magnetic particle inspection, eddy current testing, ultrasonic testing, and radiographic testing.

- Q: How are steel coils used in the manufacturing of power transmission towers?

- Steel coils are used in the manufacturing of power transmission towers as they are shaped and formed into the required structural components, such as beams and brackets. These coils are processed through rolling mills to obtain the desired thickness and shape, ensuring the strength and durability of the towers. The steel coils provide the necessary strength and structural integrity to support the weight of the transmission lines, withstand environmental conditions, and ensure reliable power transmission.

- Q: What are the environmental and social impacts of mining, processing and using steel?

- It contains less than 0.25 % carbon. These steels are hot worked and produced for beam and structural application. Low carbon steels are not hardened appreciably by hardening process of heat treatment. A decrease in carbon content improves ductility mild steels are used for wires, rods, thin sheets, solid drawn tube, boiler plates, steel joints, channels and angles, structural sections, drop forgings. they are further classifies into dead mild, and mild steel dead mild steel It contains 0.05% to 0.15% carbon. It is used for making steel wires, sheets, rivets, screws, pipe, nail and chain. It has a tensile strength of 390 N/mm2 and a hardness of about 115 BHN. there are many company which produce their products from this raw material like tube, pipe, S31803 Duplex tube fitting, pipe fitting etc

- Q: How are steel coils used in the manufacturing of construction bulldozers?

- Steel coils are used in the manufacturing of construction bulldozers as they provide the necessary strength and durability required for the heavy-duty components of the machine. These coils are typically shaped and welded to form the structural frame, blades, and bucket of the bulldozer, ensuring that it can withstand the rigorous demands of construction and earthmoving tasks.

Send your message to us

THE BEST HOT-DIP GALVANIZED STEEL COILS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords