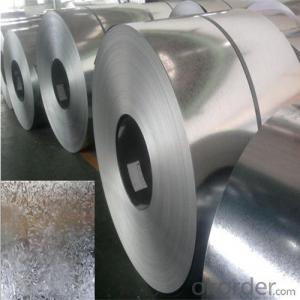

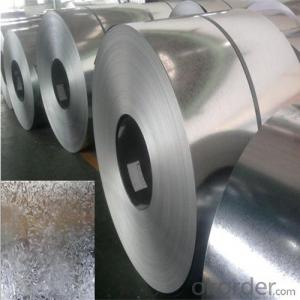

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | China (Mainland) | Brand Name: | N/M | Model Number: | ssp-226 |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: How are steel coils used in the manufacturing of industrial compressors?

- Steel coils are used in the manufacturing of industrial compressors primarily for the construction of the compressor's casing and frame. The steel coils are shaped, cut, and welded to create the sturdy and durable structure that houses the compressor components. Additionally, the steel coils may also be used in the fabrication of other parts such as motor mounts or brackets, contributing to the overall reliability and stability of the compressor.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: What is the standard length of steel coils?

- The standard length of steel coils can vary depending on the specific industry and application. However, common standard lengths range from 1000 to 6000 millimeters or 3 to 20 feet.

- Q: my step father bought a big steel drum grill it has steel sheets (very thin) that go inbetween the flame and the food (closer to the flame) with that there the food will not cook, it does not get hot enough????? please help... what should we do

- This type of grill cooks like an oven You have to keep the lid shut until the proper temp. is reached. Then place you meats and stuff on the grill and close the lid. Open the lid infrequently to keep the heat in. If its charcoal make sure you use enough charcoal the first time so you don't have to add any while you food is cooking.

- Q: Can steel coils be coated with color-changing materials?

- Yes, steel coils can be coated with color-changing materials. These materials are typically applied as a topcoat or overcoat on the steel surface, allowing the coils to exhibit different colors or hues based on external factors such as temperature, light, or chemical reactions. This coating technology can provide visual appeal, aesthetic versatility, and even functional benefits to steel coils in various applications.

- Q: How are steel coils inspected for dimensional accuracy during processing?

- Steel coils are inspected for dimensional accuracy during processing using various methods such as laser measuring systems, ultrasonic thickness gauges, and calipers. These tools are used to measure the width, thickness, and diameter of the coils to ensure they meet the required specifications. Additionally, visual inspections are also conducted to identify any irregularities or defects in the coils.

- Q: I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- Steel is magnetic, and can spark...Sparks are not good things around gun powder....CCI loads some pistol rounds with aluminum cases, but they are not re loadable, as the aluminum is so soft the primer pockets will wear out quickly..Aluminum, metallurgical, has a valence of +3, which means that moisture would cause electrolysis to set up between the steel primer cup and the aluminum case, which would pit the primer pocket...Steel is harder than brass, and would not uniformly expand on the firing sequence, and would be likely to rupture instead of expanding and sealing...Also, the hardness of steel would make resizing cases difficult, as steel needs to be heated before reshaping.......Hope this helps....

- Q: What are the dimensions of steel coils used in automotive part manufacturing?

- The dimensions of steel coils used in automotive part manufacturing can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width. The length of the coils can also vary, typically ranging from 1000mm to 6000mm.

- Q: What is the role of steel coils in the production of appliances?

- The role of steel coils in the production of appliances is to provide a strong and durable material for the construction of various components and structures. Steel coils are commonly used to manufacture appliance parts such as panels, frames, cabinets, and internal components. The high strength and versatility of steel make it ideal for withstanding the stress and demands of everyday appliance use. Additionally, steel coils can be shaped, molded, and welded to create customized designs and configurations, ensuring the appliances are both functional and aesthetically pleasing.

- Q: What are the different types of steel coil grades?

- There are several different types of steel coil grades used in various industries and applications. Some of the most common steel coil grades include: 1. Carbon Steel: This is a basic type of steel that contains mostly iron and carbon. It is widely used in construction, automotive, and manufacturing industries due to its high strength and durability. 2. Stainless Steel: This type of steel contains chromium, which provides corrosion resistance and makes it suitable for applications that require resistance to oxidation and staining. It is commonly used in the food processing, chemical, and medical industries. 3. High-Strength Low-Alloy (HSLA) Steel: HSLA steel contains small amounts of alloying elements such as copper, phosphorus, niobium, and vanadium. This type of steel offers higher strength and better mechanical properties compared to carbon steel, making it suitable for structural applications. 4. Galvanized Steel: Galvanized steel is coated with a layer of zinc to protect it from corrosion. It is commonly used in outdoor applications, such as roofing, fencing, and automotive parts. 5. Electrical Steel: Also known as silicon steel, electrical steel has high magnetic permeability, low electrical conductivity, and low core loss. It is used in the production of transformers, motors, and other electrical equipment. 6. Tool Steel: Tool steel is a high-carbon steel that is specifically designed for making tools and dies. It has excellent hardness, wear resistance, and toughness, making it suitable for cutting, forming, and shaping materials. These are just a few examples of the different types of steel coil grades available. Each grade has its own unique properties and characteristics, making it suitable for specific applications in various industries.

Send your message to us

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords