Hot-Dip Galvanized Steel Coil with Very Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

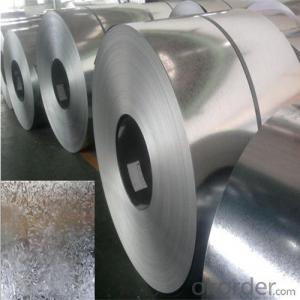

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils inspected for surface cleanliness?

- Steel coils are inspected for surface cleanliness through various methods such as visual examination, ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help identify any surface defects, contaminants, or irregularities on the steel coil, ensuring it meets the required cleanliness standards.

- Q: I have hundreds of pounds of scrap steel... who purchases this steel and what is the price per pound etc. of this? Does someone pick it up or do I bring it somewhere?

- It okorder /

- Q: i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- 316L steel is the most basic metal used in body jewelry. It is the basic requirement of metal to be used in initial piercings and for healing. There are better grades but usually they cost more as well. For most people this grade of steel works just fine. Titanium is usually preferred over steel because it contains no nickel and it weighs almost 50% less than steel. Titanium can come in plain polish which looks just like steel AND it can come in a variety of colors (but NOT red or black). Titanium is super for people with sensitive skin to steel. It does cost a little more but is well worth it.

- Q: What are the different methods of surface inspection for steel coils?

- There are several different methods of surface inspection for steel coils, each with its own advantages and limitations. Some of the most commonly used methods include: 1. Visual Inspection: This is the simplest and most basic method, where an inspector visually examines the surface of the steel coils for any defects such as scratches, dents, or discoloration. While this method is subjective and dependent on the skill and experience of the inspector, it can be a cost-effective option for detecting obvious surface defects. 2. Magnetic Particle Inspection (MPI): This method involves applying a magnetic field to the steel coil and then applying iron particles on the surface. Any defects or cracks in the surface will disrupt the magnetic field, causing the particles to gather at those areas and making the defects visible. MPI is particularly useful for detecting surface cracks and defects that may not be easily visible to the naked eye. 3. Eddy Current Testing (ECT): ECT is a non-destructive testing method that uses electromagnetic induction to detect surface defects on steel coils. A probe with a coil is placed near the surface of the coil, generating an alternating magnetic field. Any changes in the electrical conductivity or magnetic permeability of the steel due to surface defects will cause a change in the induced current, which can be detected and analyzed. ECT is effective for detecting cracks, corrosion, or other surface irregularities. 4. Ultrasonic Testing (UT): This method uses high-frequency sound waves to inspect the surface and subsurface of steel coils. A transducer sends ultrasonic waves into the steel, and the reflected waves are analyzed to detect any changes or anomalies in the material. UT can identify defects such as cracks, delaminations, or voids within the coil, providing valuable information about the overall structural integrity of the steel. 5. Optical Inspection: This method utilizes advanced imaging techniques, such as cameras or laser scanners, to capture high-resolution images of the surface of steel coils. These images can be analyzed for defects, such as scratches, pits, or other irregularities. Optical inspection can provide detailed information and is often used in conjunction with other methods for a comprehensive inspection. It is important to note that each method has its own limitations and may be better suited for specific types of defects or surface conditions. Therefore, a combination of these methods is often employed to ensure a thorough and accurate inspection of steel coils.

- Q: What are the different surface finishes of steel coils?

- There are several different surface finishes of steel coils, including mill finish, galvanized finish, painted finish, and coated finish.

- Q: should I shoot Herters .308 steel cased ammo in my Remington 7400.and why shouldn't I?

- Kudos to NXile for his/her post. Ironically, I recently posted a similar answer in this forum and got many thumbs down. The problem with the non-expansion of steel cased ammo is not limited to the blow-back and soot build-up inside the action. The other problem is that your Remington 7400 was engineered at the Remington factory as a sporting firearm that uses brass cased sporting ammunition. When you switch to the steel cased ammo, the casing doesn't have a chance to grab at the walls of the chamber to slow it down. The result is heavier recoil on the action of the gun. Over time, you will break something. Also, I don't like the idea of steel rubbing against steel inside the chamber area of a gun. I know sure sure I won't use steel cleaning rods or brushes to clean the barrel of a rifle. So why would I want to chance shooting steel cased ammo? The only stuff I will shoot steel cased ammo out of are the junky SKS and AK style rifles that I don't care about. Anything with real value...and I only use brass ammo with non-corrosive priming.

- Q: Can steel coils be stored in a humid environment?

- Steel coils should not be stored in a humid environment as high humidity can lead to corrosion and rust formation on the steel surface, compromising its quality and durability. It is important to store steel coils in a dry and well-ventilated area to maintain their integrity and prevent any potential damage.

- Q: I have been wanting a new pair of hiking boots, but haven't had the money. I just got a job that requires me to have steel toed boots. The job is only for a few weeks, but I may be required to wear them on other jobs in the future. Regardless of which style I get, I will most likely be buying Red Wing boots. On their website, I see they have steel toed hiking boots. What is the purpose of a steel toed hiking boot? Why would a hiker need to have steel toed boots? Wouldn't that just be more weight? I see that some of their hiking boots have aluminum toes, claiming to be 33% lighter than steel with the same protection. Would these boots be good potential hiking boots as well as suitable for construction or should I just focus on work boots and buy myself some hiking boots at a later date?

- Steel toed boots is a safety factor thing. Wilderness workers ie lumber jacks need safety shoes as well. But for long distance hiking steel toed shoes would be impractical due to the weight and wear and tare on The trails and your body. Get the boots you need for work, get the hiking boots you want after the next paycheck.

- Q: I want a stainless steel refrigerator that doesn't leave fingerprints and I'm looking on Lowe's website but they have too many choices and i don't have a clue what they are. The have stainless, stainless look, stainless steel, monochromatic satina, and monochromatic stainless steel. Can anyone tell me what the heck those mean? lol

- Monochromatic Stainless Steel Definition

- Q: How are steel coils used in the production of appliances?

- Steel coils are used in the production of appliances as a primary material for constructing the various components, such as the outer shells, frames, and internal structures. The coils are processed and shaped into specific sizes and forms to meet the requirements of different appliances. Additionally, steel coils provide strength, durability, and a sleek appearance to the finished appliances.

Send your message to us

Hot-Dip Galvanized Steel Coil with Very Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords