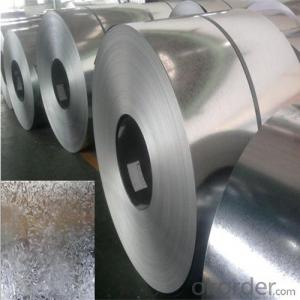

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | Brand Name: | N/M | Model Number: | ssp-226 | |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- In order to prevent rusting in the process of storage or transportation of steel roll, steel mills generally take the following packing: inner gas antirust paper wrapped with tape wrapped in plastic film sealing, intermediate, involute cardboard seal lining, cardboard corner, with iron and steel outer package corner protector, strapping fixed. If the inner package seal, so the steel coil is sank into the water, will not rust out.

- Q: I live in Dubai. I want to make a damascus steel sword and have no idea where to get the steel or what sort of steel I should get.First to adress the access of my steel...I need to get some low carbon and high carbon steel for the Damascus....what sort of steel is recommended for this? Also where would I be able to get my hands on it (Internet options e.g websites or locations)THANKS

- Damascus Steel Swords For Sale

- Q: What is galvanized steel coil?

- Galvanized steel coil is a type of steel that has been coated with a layer of zinc to protect it from corrosion. The process of galvanization involves immersing the steel coil in a bath of molten zinc, which forms a protective layer on the surface of the steel. This layer not only prevents corrosion but also provides a barrier against scratches and other damage. Galvanized steel coil is commonly used in various industries, including construction, automotive, and manufacturing, due to its durability and resistance to rust. It is often used for making roofing materials, pipes, and automotive parts, among other applications. Overall, galvanized steel coil is a versatile and cost-effective solution for ensuring the longevity and integrity of steel products.

- Q: What are the different types of steel coil storage methods?

- There are several types of steel coil storage methods, including stacking coils vertically, using coil cradles or saddles, utilizing coil racks or frames, employing coil lifters or C-hooks, and implementing automated coil storage systems. Each method is designed to accommodate different storage requirements and ensure the safety and efficient handling of steel coils.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- There are several methods of cut-to-length shearing for steel coils, each with its own advantages and applications. Some of the commonly used methods are: 1. Rotary Shearing: This method involves the use of a rotating shear blade that cuts through the coil. It offers high precision and can handle a wide range of material thicknesses. Rotary shearing is suitable for high-volume production and can achieve high cutting speeds. 2. Guillotine Shearing: In this method, a straight blade is used to cut through the coil. It is a versatile method that can handle various material thicknesses and widths. Guillotine shearing is relatively simple and efficient, making it a popular choice for many applications. 3. Slitting: Slitting involves making multiple longitudinal cuts in the coil to create narrower strips. It is commonly used when a coil needs to be divided into several smaller coils or when narrower strips are required for specific applications. Slitting can be done using either rotary or straight blades. 4. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the material, resulting in a clean and precise cut. It is ideal for cutting complex shapes or patterns and can handle both thin and thick steel coils. Laser cutting offers high accuracy and minimal material distortion. 5. Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through the coil. This method is suitable for a wide range of materials, including steel, and can achieve high accuracy. Waterjet cutting is often used for cutting thick coils or when heat-affected zones need to be minimized. Each method has its own strengths and limitations, and the choice depends on factors such as material thickness, required precision, production volume, and specific application requirements. The selection of the most appropriate method is crucial to ensure efficient and high-quality cut-to-length shearing for steel coils.

- Q: How are steel coils used in the production of automotive stampings?

- Steel coils are an essential component in the production of automotive stampings. These coils are typically made from high-quality steel and are cut into specific widths and lengths to meet the requirements of automotive manufacturers. The first step in using steel coils for automotive stampings is to uncoil the steel. This is done using a machine called a decoiler, which unwinds the coil and feeds it into the stamping machine. The decoiler ensures a continuous supply of steel for the stamping process. Once the steel coil is unwound, it is fed into the stamping machine, which is equipped with a die that shapes the steel into the desired automotive component. The die is designed to create precise and complex shapes, such as car body panels, doors, fenders, or structural components. The stamping machine applies force to the steel coil, pressing it against the die and forming it into the desired shape. The high-quality steel used in the coils ensures that the stamped components have the necessary strength and durability required for automotive applications. After the stamping process, the stamped components are inspected for quality and precision. Any imperfections or defects are identified and corrected before the components are sent for further processing, such as painting, welding, or assembly. Overall, steel coils play a crucial role in the production of automotive stampings. They provide a continuous supply of high-quality steel, which is shaped into precise and durable automotive components. The use of steel coils ensures that the automotive stampings meet the required standards for strength, durability, and precision.

- Q: What are the common quality issues with steel coils?

- Common quality issues with steel coils include surface defects such as scratches, rust, or mill scale, dimensional deviations, coil breaks or bursts, edge wave, and coil set. Other issues may include variations in chemical composition, hardness, or tensile strength, as well as improper winding or packaging, which can lead to damage or deformation during transportation or storage.

- Q: What is the maximum length of a steel coil?

- The maximum length of a steel coil can vary depending on various factors such as the type of steel, manufacturing capabilities, and transportation logistics. However, in general, steel coils can be several hundred meters long, with some specialty coils exceeding a kilometer in length.

- Q: What are the different coil winding methods used for steel coils?

- Steel coils can be wound using various methods, each having its own benefits and uses. 1. Layer winding is the most commonly employed technique for steel coils. It entails winding the steel strip or sheet in concentric layers to create a coil. This method is suitable for narrow and thin strips, offering excellent coil stability and strength. 2. Cross winding involves winding the steel strip in a crisscross pattern, alternating the direction of each layer. This ensures even stress distribution and prevents coil instability. Cross winding is typically used for wider or thicker steel strips. 3. Spiral winding is utilized for large or heavy steel coils. The steel strip is wound in a spiral pattern, gradually increasing the coil's diameter. This method facilitates easy handling and transportation while providing stability and preventing coil collapse. 4. Toroidal winding is employed to produce toroidal or donut-shaped coils. The steel strip is wound in a circular path, with each layer placed inside the previous one. Toroidal winding is commonly utilized in applications like transformers, where specific coil shape and size are required. 5. Interleaved winding involves intertwining two or more steel strips during the winding process. This method is used to create composite coils with varying materials or thicknesses. It enhances strength, stability, and enables customized designs. The selection of a specific coil winding method depends on factors such as strip thickness, width, tensile strength, and desired coil properties. Each method offers unique advantages and is chosen based on the specific requirements of the steel coil application.

- Q: Hi, I need to know why stainless steel is rust proof please tell me its for my science project. :)

- Stainless steel is characterized by the presence of chromium. Chromium oxidizes like aluminium does, by passivation, that is, it forms a though oxide layer that sticks to the metal underneath and protects it. On the other hand, iron oxidizes by turning into rust, which is a brittle material that flakes off, exposing the metal under for more oxidation. Now, what happens when you have a metal that is made of both iron and chromium? Any iron on the surface will rust and flake off (at the atomic level, so do not expect to see much rusting) until the surface is a pure chromium layer (again, we are talking about a layer that is a few atoms thick) and that chromium will oxidize but stay put. Then rust then has no way of getting deeper, and the metal will remain clean.

Send your message to us

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords