Aluminum Sheet Coil for Solar Cell Frame - Color Coated Houston

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

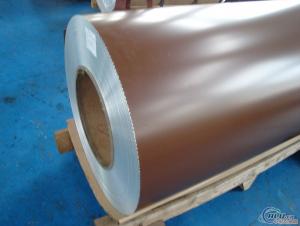

Color Coated Aluminium Roll For Solar Cell Frame

Specifications

Grade | 1050,1060,1070, 1100, 1200, 2024,3003, 3004,3005, 3105, 5005,5052 5182,5754,8011 etc |

Thickness | 0.1~1.5mm |

Width | 100~2500mm |

Surface Treatment | PVDF and PE coated |

Temper | O-H112 |

Hardness | More than 2H |

Yield(≥MPa) | 160 |

Ultimate Strength(≥MPa) | 175 |

Elongation(≥%) | 6 |

Packing Material | Moisture-proof agent, steel tape bundle, wooden pallet, brown paper |

Method | Vertical(eye to sky) or horizontal(eye to wall) |

Standard Specification | 1000mm×C, 1200mm×C, etc |

Shipping | Container Loading or Bulk Pack |

Characteristics

1) Excellent weather-proof durability

2) Anti-ultraviolet

3) High erosion resistance

4) Stable color and gloss

5) Good mechanical processing performance

6) Abrasion resistance

7) Anti-impact

8) High flexibility

Application

1) Construction material further processing

2) Solar cell frame, solar battery frame

3) Glass curtain wall frame

4) Interior decoration

5) Elevator decoration

6) Signs, nameplate, bags making.

7) Automobile parts material

8) Office and Household appliances: HVAC equipments

9) The consumer electronics: mobile phones, digital cameras, MP3 .etc.

Coating varieties

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What’s the coating of top side?

--A: PVDF and PE coating

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112, T3, T4, T6

- Q: What are environmentally friendly types of aluminum coil and do they exist?

- <p>Yes, there are environmentally friendly types of aluminum coil. These include recycled aluminum coils, which are made from aluminum that has been reprocessed and reused, reducing the need for new aluminum production and its associated environmental impact. Additionally, aluminum coils with a high recycled content are considered eco-friendly as they contribute to waste reduction and energy conservation. The production of recycled aluminum uses significantly less energy compared to virgin aluminum, making it a more sustainable choice.</p>

- Q: Can aluminum coils be used for HVAC condenser coils?

- Yes, aluminum coils can be used for HVAC condenser coils. Aluminum is a popular choice for condenser coils due to its excellent heat transfer properties, durability, and resistance to corrosion. Additionally, aluminum coils are lightweight, making them easier to install and transport.

- Q: Can aluminum coils be used in the production of aluminum composite windows?

- Yes, aluminum coils can be used in the production of aluminum composite windows. Aluminum coils are commonly used in the manufacturing process of aluminum composite windows. These coils are made from high-quality aluminum and are often used as the raw material that is then formed and shaped into the desired window frames and components. Aluminum coils offer several advantages in the production of aluminum composite windows, including their lightweight nature, durability, and resistance to corrosion. These qualities make aluminum coils a suitable choice for manufacturers looking to produce high-quality and long-lasting aluminum composite windows.

- Q: What are the common sizes of aluminum coils available?

- The common sizes of aluminum coils available vary depending on the specific application and industry. However, some standard sizes include widths ranging from 36 inches (91 cm) to 72 inches (183 cm) and thicknesses between 0.019 inches (0.048 cm) to 0.125 inches (0.318 cm). These sizes are commonly used in industries such as construction, automotive, and manufacturing.

- Q: Are aluminum coils suitable for heat exchangers?

- Yes, aluminum coils are suitable for heat exchangers. Aluminum has excellent thermal conductivity, corrosion resistance, and lightweight properties, making it an ideal material for heat transfer applications. Aluminum coils can efficiently transfer heat between fluids in heat exchangers, making them a popular choice in various industries.

- Q: How are aluminum coils used in insulation applications?

- Aluminum coils are commonly used in insulation applications due to their excellent thermal conductivity and durability. They are typically used as a component of HVAC systems, where they are used to transfer heat between the air and the refrigerant in order to control the temperature of a space. In insulation applications, aluminum coils are often used in the production of air conditioning units, heat pumps, and refrigeration systems. These coils are designed to efficiently transfer heat, allowing for the effective cooling or heating of a space. The coils are typically made of aluminum due to its high thermal conductivity, which enables the efficient transfer of heat. Additionally, aluminum is lightweight and corrosion-resistant, making it a suitable choice for applications that require durability and longevity. Aluminum coils are commonly used in conjunction with other insulation materials such as foam or fiberglass to create a thermal barrier. This combination helps to minimize heat transfer between the inside and outside of a building, reducing energy consumption and improving overall energy efficiency. Furthermore, aluminum coils can be easily formed into various shapes and sizes, allowing for customization and flexibility in insulation applications. This versatility makes them suitable for a wide range of insulation needs, from residential to commercial and industrial settings. In summary, aluminum coils play a crucial role in insulation applications by efficiently transferring heat and contributing to energy efficiency. Their thermal conductivity, durability, and versatility make them an ideal choice for various insulation needs, helping to create comfortable and energy-efficient environments.

- Q: I heard that one pound of aluminum pop tabs are worth more then a pound of aluminum pop cans. Is this true? Thank you.

- yup.. but not to you. You get the same ammount turning in the tabs as you would the whole can. They can process the tabs faster and more efficently due to lack of extra printed on them.

- Q: and alsoHow many grams of the decay product will have formed after 8 days go by?The decay product is the new isotope created as a result of the positron decay of aluminum-24.In class my teacher didn't explain this completely but there's a question on the homework that me and even my mom (another teacher) can't find the answer to.

- so it 6000/ (2*8*24*60*60) 0.00434027778 grams have you heard of the internet an unless your mom is a chem teacher it doesnt mean much

- Q: Can aluminum coils be used for structural purposes?

- No, aluminum coils are typically not used for structural purposes as they lack the necessary strength and rigidity required for structural applications.

- Q: This question asks for methods to prevent rusting on aluminum coils during storage and transportation.

- <p>To prevent rusting on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Use a protective coating or wrapping to shield them from moisture and contaminants. Store the coils in a cool, dry place away from direct sunlight and corrosive substances. Avoid stacking them where they may come into contact with acidic materials. During transportation, secure the coils properly to prevent movement that could lead to scratches or damage. Use moisture-resistant covers to protect them from the elements. Regularly inspect the coils for signs of corrosion and address any issues promptly.</p>

Send your message to us

Aluminum Sheet Coil for Solar Cell Frame - Color Coated Houston

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords