CNBM Supply Wear Resistance TPU Clear FilmTPU Non-Toxic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Pallet Wrapping

Compacting & Bunding

Shipping

Handling & Protection

Moving & Storage

Garden

Home

ndustrial & Commercial

DIY

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

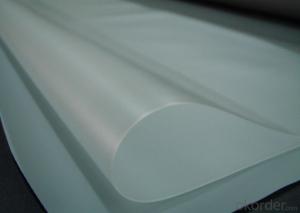

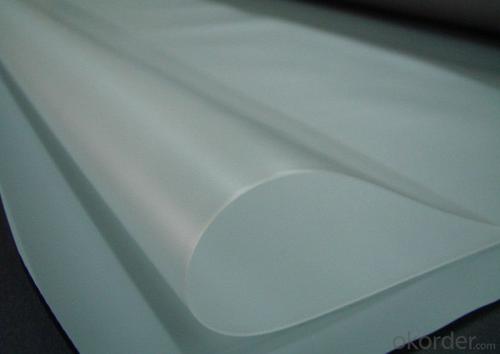

5.Pictures of TPU Film

6.Specification of TPU Film

1)thickness0.012mm~1mm

2)width:1-2 m

3)longth:<(=)1500m< span="">

4)colour:can be coloured as requirements

5)180° Strip Force:0.3N/25mm~3.0 N/25mm

6)viscous force(40,1kg):>(=)24h

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the unique properties of PET protective film?

- Property 1: Highly adhesive, fairly sticky and anti-solvent. When used in the normal temperature environment, the sidelines of the film stay straight and no glue remains. Use: Apply to decoration and ordinary industrial sheltering. Property 2: Excellent whether resistance. Apply to use at temperature below about 150℃. No residual glue. And the boundary of color separetion is clear. Use: Apply to car color covering and industrial machinery painting. Property 3: Special PET material with high tensile strength as well as acid and alkali-resistance. No permeation and no residual glue. Use: Apply to spray paint at high temperature. The film is made from sprcific materials, making it resistant to high temperature and environmental friendly. Once coated, the film will not fall off. And no glue will remain. It's the best choice for the protection of coatings like LCD, ITO, PMMA and PC. The Hualibao company is working on protective films. You can go there to learn more about PET protective films. It is suitable for automobile color cover.

- Q: Import PET protective film has those good introduction?

- Organic or inorganic glass lenses, various metal, electroplating plates, stainless steel, aluminum profiles, steel plastic profiles, aluminum plastic panels, glass panels, various types of paint panels, high-grade furniture, stone and other materials surface protection

- Q: The finish of my house has been done for years. But the protective film on the marble surface wasn't removed at that time. Now it gets difficult to remove. What I can do?

- Using lacquer thinner.

- Q: How to clean up the protective film on plastic steel doors and windows?

- Scratching the film using the tip of wallpaper cutter along the wall and then tearing it off by hands.

- Q: what are the features of AR protective film? What are the differences between it and other protective films?

- Protective film made from AR material is the best protective film on the market at present. AR material is a kind of synthetic material, generally composed of three layers: silica gel as the adsorbed layer, PET as the interlayer and outer layer as the special processing layer. And the special processing layer can be further classified into AG processing layer and HC processing layer. AG processing refers to Anti-Glare processing which is used in matte protective film. HC processing is Hard Coating processing, used in protective film with high light transmittance. AR protective film features the effect of non-reflective screen and high light transmittance which exerts no affect on the display of screen. Besides, the surface is specially treated to soften it and make it scratch-resistant and friction-resistant. No scratch leaves on it even after a long time of using. The chemical material silica gel is used as binder to stick the film to the screen without damaging the screen and marks left on it. What's more, it is washable and reusable. At present, it has become the major research object of some famous manufacturers of protective films like OK8 and BENKS. It's easy to buy on the market. But it's more expensive than that made from PET material.

- Q: The family has three or four months of baby, my mother let me tear up, said airtight, the mother-in-law said no, said is easy to dirty, how should I deal with?

- Of course, tear it off. The film is only a protective film for the outer packing, which protects the mattress from being soiled before shipment or during transportation. Really buy home when you must tear, so that the use of the process will play an original role in health care

- Q: What harm can the resin used in protective film do?

- Most of such resin contains benzene ring. But there is substituent group on the benzene ring that can be easily eliminated from human body by metabolism. Therefore, compared to benzene, it does less harm to human body because it has less toxicity. Besides, halohydrocarbon also has a certain toxicity and also does certain harm to human body and environment.

- Q: Are PET silicone protective films the same for PE films?

- The PET film has no extensibility, deformation and good hardness. 3, from the application point of view, the product surface protection PE protection film for aluminum plate, aluminum plate, metal surface, plastic sheet surface, construction and decoration materials, polyester furniture, stone, steel, automotive interior, Aluminum Alloy, organic glass, electronics, home appliances, IT industry

- Q: How to remove the protective film on tiles?

- Sprinkle some industrial alcohol on the floor for three minutes, then wipe with a duster. It's easy and fast.

- Q: How many kinds of glue do you want to protect the film?

- The basic acrylic oil, glue and water gel, as well as silicone and rubber. The performance of silica gel is better, exhaust performance and stability are higher.

Send your message to us

CNBM Supply Wear Resistance TPU Clear FilmTPU Non-Toxic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches