Bulletproof Laminating Glass TPU Film High Transparent TPU Film of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Household: shower curtain, table cloth, raincoat, umbrella

Bags: cosmetic bags, ziplock bag, cooler bags(liners)

Stationery: book cover, card holders/jackets, binders

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

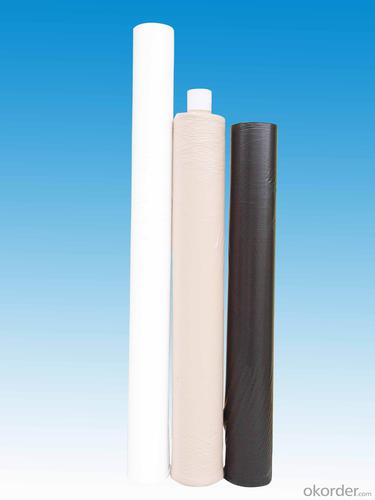

5.Pictures of TPU Film

6.Specification of TPU Film

Item Name: TPU film

Thickness: 0.025MM - 1.0MM

Total Weight: 20 - 1300g/m²

Color of TPU Film: Translucent

Width: 100-200CM

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I am a beauty shop, into a number of forming universal car door, bowl, protective film, but how all paste is not good, not wrinkled, that is, there are bubbles can not get out, what is a good way to paste it?

- You won't first ask an expert to come over and stick to it once. If you learn it once more, don't you OK?

- Q: What can chemically react with protective film of ceramic tile?

- The protective film coated on ceramic tiles is a kind of PE film. The PE in PE protective film refers to Polyethylene. It's a kind of macromolecule organic compound with the simplest structure. And it's the most widely used polymer material in the world today. PE prtective film uses specific PE plastic membrane as its basic material. Accoding to density, PE film can be classified into high-density, medium-density and low-density PE film. The biggest advantage of PE film is that it can protect the product from pollution, corrosion and scratching throughout the whole process from production, processing, transpotation, storage to end use. It keeps the product clean and glossy which means to improve the quality and market competitiveness of the product.

- Q: Cell phone protective film on the small label to tear off the top, as well as how to remove plastic glue?

- Don't eraser, this will make the screen of mobile phone very wear off. You go to buy a mobile cleaner, and then quickly wipe with the eye wipe gently wipe it

- Q: How many degrees is the highest temperature that PE protective film can resist?

- The property of high-temperature resistant of PE flim is not very good. It's all about time. PE film can resist temperature of 80 degrees for a short time and 40 degrees at most for a long time. Otherwise problems may occur, which are, for example, the film may be easy to curl or fall off.

- Q: How to prevent the protective film from damage and the stainless steel from marks when drawing the steel?

- The surface quality of drawing dies of stainless steel is highly required. Rough surface can decrease friction and increase the property of adhesive resistance. Therefore, after the grinding processing, the more important work is to remove the processing marks left on the drawing dies. However, few people know the importance of the grinding and polishing processes when making dies. Throughout the whole process, the proportion of grinding and polishing processes should reach one third because the appearance quality of stainless steel products,to a large extent, is determined by the grinding and polishing techniques of making dies. The rougher the surface of dies is, the less it needs re-grinding. And the life of the dies also extends accordingly. If the surface of dies is not well grinded and polished, the marks on the drawn products will be clear. Although there's something to do with the fact that drawing stainless steel can easily cause seizing tumour, too. And to polish these marks takes time and the result is not good. Thus we should pay more attention to the grinding and polishing processes. Only when the surface processing precision of dies improves, can the marks decrease and the life of dies extend. In recent years, various new polishing techniques and polishing tools have arised at home. New processes and equipments such as ultrasonic polishing, electropolishing, abrasive jet and extrusion honing have been developed.

- Q: The way to distinguish acrylic glue from silica gel.

- The states of existence of acrylic glue and silica gel are different. Thus their effects are different.

- Q: What to do if the adhesion of the PE protective film is too high?

- PE protective film in industry is made of acrylic acid PSA coating (Silica gel is mainly used in PET protective film). The adhesion of protective film is determined by the proportion of original gum and the amount of glue. In the process of application,though, PSA protective film has problem of high adhesion because of the high stickiness of itself.It's directly related to covering and the storage of pressure and temperature. As is known to all, PSA glue is only sensitive to stress. You can adjust the pressure stored when or after the covering. If the protective film itself has high adhesion, you can try to use it when it cool down (Using at temperature below 20℃, you will clearly feel the adhesion comparatively decreased).

- Q: How many kinds of material are there in the decoration ground protection film?

- Many colors, the most common are transparent, blue, black and white, milk white, in addition, there are black, gray, green, yellow, orange, gold, red and so on. The colors of PET are transparent, gray, and golden.2, CPP is usually frosted, fog like effect of the film3, PVC common is transparent, with blue transparent electrostatic film4 and OPP are usually transparent tape

- Q: How to remove the protective film on the door cover and window cover in a quick way?

- You can try to heat the film with electric hair drier and then tear it off.

- Q: Is there a protective film on the surface of the LCD screen? Can you wipe it directly with a wet cloth?

- Take a wet rag and rub it on the screen, wiping out the protective film that appears on the screen, causing the screen to blur. If too hard, even the screen will be cut, so that liquid crystals flow out.

Send your message to us

Bulletproof Laminating Glass TPU Film High Transparent TPU Film of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches