Waterproof Breathable TPU Film, Good Elasticity, High Strength of CNBM in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

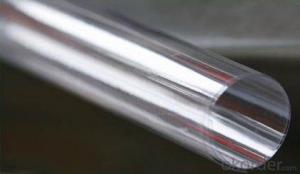

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Pallet Wrapping

Compacting & Bunding

Shipping

Handling & Protection

Moving & Storage

Garden

Home

ndustrial & Commercial

DIY

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

5.Pictures of TPU Film

6.Specification of TPU Film

| Item | Test Standard | Unit | Value | |||||||

| Density | ISO1183 | g/cm3 | 1.21±0.02 | |||||||

| Hardness | ISO868 | Shore A | 98±3 | |||||||

| 100% Modulus | ISO37 | Mpa | 15 | |||||||

| 300% Modulus | ISO37 | Mpa | 25 | |||||||

| Tensile Strength | ISO37 | Mpa | 39 | |||||||

| Elongation | ISO37 | % | 420 | |||||||

| Tear Strength | ISO34 | KN/m | 140 | |||||||

| Anti-yellowing | ASTM-D 1148 (A) | Grade | 3 | |||||||

| ASTM-D 1148 (B) | Grade | 3 | ||||||||

| Compression Set, 70℃ | ISO815 | % | 58 | |||||||

| Abrasion Resistance | ISO4649 | mm3 | 55 | |||||||

| All test slabs need to be post cured at 100 degree C*16 hrs for further physical property test. | ||||||||||

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Do I need to tear off the protective film on the mattress?

- You must tear it off, or the mattress will mildew.

- Q: How to define the adhesion degrees of protective film?

- At present, there's no such internatinal standards. Each company has its own standards. It's for reference that the adhesion of protective film is usually classified into four degrees which are slight, low, meidium, and high. Generally, 0.02-0.1N refers to slight degree; 0.1-1N,low degree; 1-2N, medium and 2-6N, high. But this is not always the same. It depends on the requirements of themanufacturers.

- Q: Is computer screen protective film effective?

- To be sure, it didn't work. I bought a protective film, or it was more expensive

- Q: The mirror protective film is what, how should the truth!

- If you are always playing games with mobile phones or reading e-books, it's better not to post them.

- Q: What's the coating for paint?

- TPU's ductility, scratches, and automatic restoration capabilities are excellent. Of course, the protective coating on the TPU material is also common now, and if you want it better, look at its coating structure

- Q: After the camera is attached, some bubbles want to be replaced with another one. How can you pull it out? It's urgent. Can you stick it in a little water? Oh, that's tough

- The new film machine in the factory when the film strip is not in the true sense, is only a PE film, the main purpose is to ensure that the mobile phone in the factory to the packaging process of the screen is not easy to paste the razor, so this time the film, the film after storage to lose adhesion, easy tear at on the screen, so you need to buy a professional film at the time of the sale, or to allow merchants to send the film to you, but businesses in order to control the cost, when the mobile phone sales are sent scratch proof film, ordinary general quality, according to statistics, 97% of users lose business sent film in use for a period of time later, because the scratch degree is very poor, so I recommend you to understand the film VDOO, is also very cheap to buyMobile phones, cameras, notebooks, LCD TV film has the advantages of functional benefits

- Q: What to do if the adhesion of the PE protective film is too high?

- If the adhesion is too low, it may be difficult to tear the film down from the coated product. If the adhesion is too high, then it may be easy to fall off.

- Q: What's anti-blue-ray film used for?

- It has function of anti-ultraviolet-rays that can reflect visible light of harmful rays of 380nm-420nm and short wave blue ray. It's 100% anti-ultraviolet-rays of UV400. It can protect the eyes in particular.

- Q: How to solve the crystal point on the PE protection film?

- The main reason of the crystal point of the PE protective film is the following reasons:1, the cleanliness of raw materials, including the cleanliness of the raw material itself and the dust pollution of the environment; therefore, attention should be paid to the production of PE protective films.

- Q: What are the differences between PE protective film, PET protective film and PVC protective film?

- PE refers to polyethylene. It's commonly used in protective films, featuring low price, softness, excellent ductility and environmental friendliness. Generally speaking, products made from this kind of material must pass the ROHS environmental pollution tests stipulated by European Union. Its disadvantage is poor whether resistance. It's not suitable to be used at temperature more than 60℃. PVC refers to polyvinyl chloride. Its features are good softness and whether resistance. And its disadvantage is non-environmental-friendly. Thus many big international brands rarely use this kind of material. Products made from this kind of material are mainly used for anti-static protection or as the surface of wooden stereo. PET refers to polyester. Its major property is good whether resistance which makes it resistant to high temperature of 100℃ to 150℃, hardness and flatness. And its disadvantage is that it can't be used on angular products.It's mainly used in die cutting.

Send your message to us

Waterproof Breathable TPU Film, Good Elasticity, High Strength of CNBM in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches