High Quality Waterball TPU Film of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Cloth materials , laminated with fabric material or garment material using in raincaot, wind coat, field jacket, baby diaper and so on.

Shoes materials, laminated with fabric materials using in sport shoes, climbing boots, golf shoes as lining materials or shell materials.

Medical materials, use to make surgeon gown, protective clothing, medical mask, medical sheet, medical glove, blood bag and so on.

National defense materials, use to make tent, water bag, life jacket, inflatable boat and so on.

Daily necessities materials, use to make table cloth, plastic toys, sheet, shower curtain, apron and so on.

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

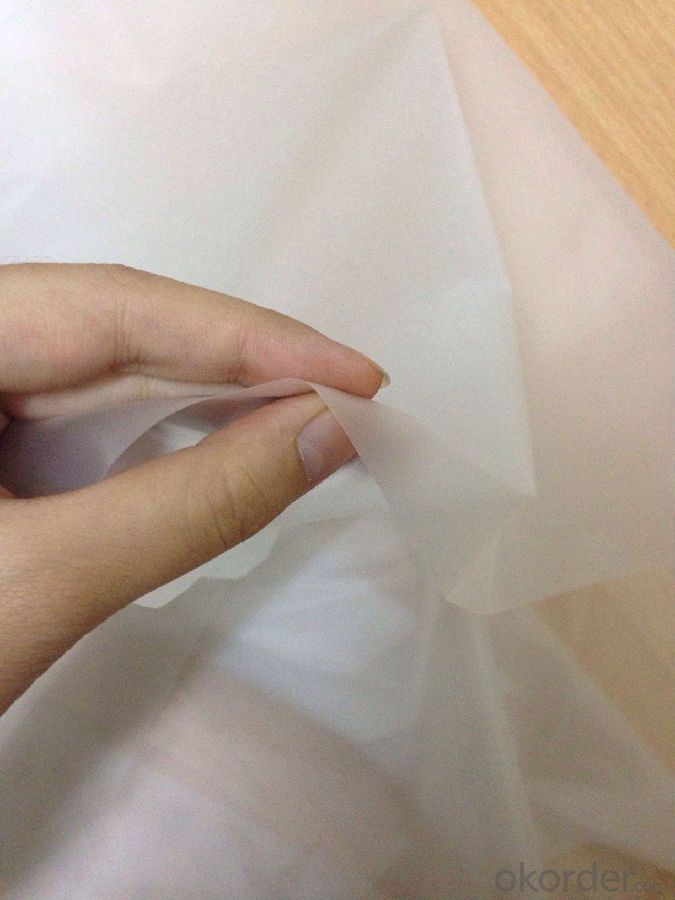

5.Pictures of TPU Film

6.Specification of TPU Film

Waterball TPU film

.High flexibility and environment-friendly material, widely used for water ball,bags,water bladder.

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

1.

- Q: Can the human body have an invisible protective film? If you pull out your soul, you'll come out

- Cells form tissues, tissues and organs, and organs make up the human body. Human beings begin with fertilized eggs, and embryos develop continuously. In the human brain, there are a lot of bioelectricity, pulse and so on. The bioelectricity information still remains after the death of the human body, and the human brain dies, but the brain activity is not completely stopped. This is science, and it will die in a few days or even months. After death, these bioelectricity can move in various forms in nature. These are science, but what you say is completely wrong. Even junior high school biology knows you, that's a fallacy

- Q: How to distinguish release film from protective film with the naked eye?

- In fact, the protective film is relatively the use layer. It's thicker than release film. But release film is used to protect the use layer. Usually, PET use layer can not only be formed by PET release film, but also by PE release film. To put it simple, generally the middle layer is the use layer. The outer layers are all release film which are usually thinner than the use layer.

- Q: How to test the adhesion of protective film?

- This is kind of test is called performance test. Taking five layers of the protective film as the teat specimens and test separately according to GB/T 7124. And the final result will be the arithmetic average of the results of the five teat specimens. By the way, what kind of thing do you use the film on?

- Q: How to use super light clay to make transparent protective film?

- As for clay, especially the soft type, if you apply protective oil before it's complete dry, indentations may remain at the last stage of pressing.

- Q: Use of protective film for decoration

- Through the use of protective film to protect floors and doors and other products, can effectively prevent scratches or crash floor tiles and doors, reducing the risk of unnecessary losses during renovation.Hope to adopt

- Q: The finish of my house has been done for years. But the protective film on the marble surface wasn't removed at that time. Now it gets difficult to remove. What I can do?

- Apply some essential balm or detergent to the marble surface and cover the surface with preservative film. Press out the air between the surface and the film. And then tear off the film a minute later.

- Q: How long is the screen left on the screen of the mobile phone for a long time?

- Residue on the mobile phone, the general cleaning professional cleaning agent, cleaning agent recommended by PHILPS, the effect is very good; if there is no cleaning agent, can dilute the home cleaning agent, use a soft cloth dipped in cleaning a little bit, do not dip too much, avoid water clean screen mobile phone after using a clean cotton wipe clean

- Q: The family has three or four months of baby, my mother let me tear up, said airtight, the mother-in-law said no, said is easy to dirty, how should I deal with?

- Some suggestions for the maintenance of mattresses:1. turn regularly. The new mattress during the first year of purchase, every 2 to 3 months, positive or negative, or around the corner to turn each other, so that the mattress spring force evenly, and then about once every six months can turn.2. keep clean. To do a good job bedding hygiene, sun drying. If the mattress stain, you can use toilet paper or cloth to suck moisture, not washed with water or detergent. Avoid lying in bed after sweating or after sweating, or using electrical appliances or smoking in bed.3., do not often sit on the edge of the bed, bed angle. Because the 4 corners of a mattress is the most fragile, long in the edge of the bed sit, easy to make the edge damage early spring.

- Q: Do you know if there is a computer screen that can be seen only from the front?

- I know what kind of film you're talking about! You're talking about an anti peeping film!!! The price is not very cheap!! The retail price is above 150!!! The film is attached to the computer and cannot be seen at a certain angle! But the transmittance is not very good!

Send your message to us

High Quality Waterball TPU Film of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches