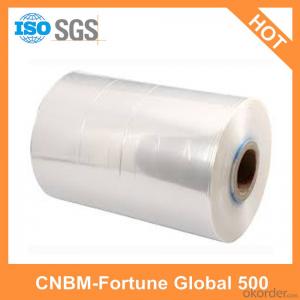

Shanghai Clear Book Environmental TPU Film Manufacturer of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Household: shower curtain, table cloth, raincoat, umbrella

Bags: cosmetic bags, ziplock bag, cooler bags(liners)

Stationery: book cover, card holders/jackets, binders

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

5.Pictures of TPU Film

6.Specification of TPU Film

Item Name: TPU film

Thickness: 0.025MM - 1.0MM

Total Weight: 20 - 1300g/m²

Color of TPU Film: Translucent

Width: 100-200CM

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the thickness of PET protective films?

- PET protective film usage layer, common thickness of 3C, 6C, 8C, 12C, 15C and so on.

- Q: How safe is your slice of graphite?

- Organic or inorganic glass lenses, various metal, electroplating plates, stainless steel, aluminum profiles, steel plastic profiles, aluminum plastic panels, glass panels, various types of paint panels, high-grade furniture, stone and other materials surface protectionIn addition to Dongguan, East America's protective film is the best, I really can not remember who else

- Q: How to remove the aging protective film on plastic steel doors and windows?

- It is pretty annoying. You can try to heat it with electric hair drier and then tear it off.

- Q: How many kinds of electroplating protective film are there?

- Electroplating protective film is often used in gas deodorization, liquid decolorization or cleaning of the organic contaminations in plating bath in particular. Products like aluminium products can use method of anodization. There will form a layer of protective film of crystalline aluminium oxide.

- Q: What's the meaning of 3.0 H in anti-scratch protective film 3.0H?

- It means that there will be no scratches on the surface of the film! The price is about three times than that of OK8. The cost effectiveness is quite high. But the performance is not good!

- Q: Why should tear off the protective film on kitchen ventilator?

- It's up to you. If you like it clean, then keep it coated. If you want to see the protective film without anything covering it, you can just tear off the film.

- Q: When you remove the protective film from your cell phone, how can you remove the glue?

- Can be removed with an eraser or alcohol.Ethanol (alcohol) is a good solvent, can dissolve many inorganic compounds, and can dissolve many organic compounds, so commonly used ethanol to medicinal ingredients dissolved or the plant pigment; also used ethanol as reaction solvent

- Q: What's the reason why watermarks are easy to appear on protective film of high adhesion?

- NOTE: Standard protective film is anti-static. You can't feel it adhesive by hands. It's the only choice of high-class digital camera and digital vidicon. Some protective films on the market is very sticky because it's just a layer of plastic film coated with glue. There may be bubbles or watermarks on the screen after you cover it on the screen. The display effect will be very bad. And this kind of film is very difficult to remove. It's even more difficult to clean up the glue. Remember it: if you really cherish your cell phone, digital camera or digital vidicon,NEVER use this kind of film on it!

- Q: How to change the screen of mobile phone screen?.

- (3) along the direction of the film gently pushing credit card or hard plastic sheet, film direction do gently pushing, the purpose of doing so is to ensure that no film produced in the process of pushing the bubble, while at the same time, while also observed fit part whether there is a bubble, once found on bubbles. Should gently lift, remove dust to continue after the operation, if completely good, then there are bubbles, remedy is not easy.5, completely paste flat, and slowly tear the surface of the second sub membrane. If the model screen is depressed, you can stick it with a strong adhesive glue.

- Q: How to tear off the protective film on the stainless steel security door?

- The reason why you can't remove the film is that the outer film made from polyethylene material chemecally reacts with the surface paint of the door. And the film and the paint stick to each other. You can clean the film with some of the paint using thinners. But I think it doesn't affect too much.

Send your message to us

Shanghai Clear Book Environmental TPU Film Manufacturer of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords