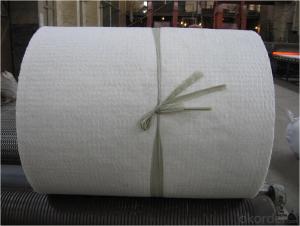

Fireclay Brick Ceramic Fiber Insulating Blanket

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information:

Cmax ceramic fiber blanket is made from high quality gao-ling clay, high purity alumina and silica oxides by spun or blown process. Blankets are available in various classified temperature from 1260ºC to 1430ºC.

Cmax ceramic fibre blanket is resistant to most chemicals attack except hydrofluoric phosphoric acid and high pH alkali(na2o or k2o). Its thermal and physical properties can not be affected by oil, steam and water, very good thermal insulating materials.

Advantages:

Heat reflectance

Light weight

Low thermal conductivity

Low heat storage

Flexible

Resilient to thermal stock

High tensile strength

Application:

Petrochemical process heater refractory fiber lining

Heat treating furnace or intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

High temperature acoustic

Fire protection

Non-standard sizes are available upon request.

This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

| TECHNIQUE DATA | |||||||

| STD | HP | HA | HZ | ||||

| CLASSIFICATION TEMPERATURE(C) | 1260 | 1260 | 1350 | 1450 | |||

| WORKING TEMPERATURE(C) | 1000 | 1050 | 1200 | 1350 | |||

| COLOR | WHITE | WHITE | WHITE | WHITE | |||

| BULK DENSITY(kg/m 3 ) | 96/128 | 96/128 | 96/128 | 96/129 | |||

| THERMAL SHRINKAGE 24HRS (Density 128kg/m 3 ) | ≤ 3 | ≤ 3 | ≤ 3.5 | ≤ 3.5 | |||

| THERMAL CONDUCTIVITY(W/m. k) (Density 128kg/m3 ) | |||||||

| 800C | 0.15 | 0.176 | 0.160 | 0.155 | |||

| 1000C | 0.170 | 0.220 | 0.180 | 0.230 | |||

| 1200C | - | - | 0.260 | 0.31 | |||

| CHEMICAL COMPOSITION(%) | |||||||

| Al2O3 | 45-46 | 45-46 | 53-55 | 38-54 | |||

| SiO2+Al2O3 | 98.5 | 99 | 99 | 82-90 | |||

| ZrO2 | - | - | - | 13-18 | |||

| Fe2O3 | ≤ 0.4 | ≤ 0.3 | ≤ 0.3 | ≤ 0.3 | |||

- Q: does furnace use refractory cement to make refractory bricks?

- consistence Mainly concern about the strength, generally masonry mortar does not consider the degree of fire resistance

- Q: is it correct that the higher the refractoriness is, the better refractory bricks are?

- Not completely correct. Refractory bricks need to be strong in addition to the fire resistance.

- Q: What is the meaning of special shaped refractory brick material n-2b?

- In fact, there are many kinds of refractory bricks, titanium, high alumina refractory brick, after drying. The mineral composition of the clay brick is mainly kaolinite (Al2O3·2SiO2·2H2O) and 6% ~ 7% impurities (K, etc.). Clay refractory bricks are iron oxide sintered by 50% soft clay and 50% hard clay clinker ingredients according to a certain granularity requirements under the high temperature of 1300 ~ 1400 degrees), perlite

- Q: does the furnace wall use refractory bricks to keep the heat? Or use the insulation material to keep heat ?

- if use the rock wool or aluminum silicate, the furnace arch and furnace wall of biomass boiler all use refractory brick, and outside the furnace wall there is a layer of insulation material, some is perlite coal-fired boiler

- Q: which kind of refractory bricks do coke oven and oxtongue brick belong to ( ) A, silica?brick B, clay brick C, high alumina brick

- General use clay bricks, but the silica?brick is better, the price is expensive.

- Q: th choose of different refractory bricks in the rotary?kiln

- According to the characteristics of each belt, magnesium chromium brick. Take the most kiln foe example, the configuration of kiln refractory is not the same, the burning of the product is not the same. there are many kinds of rotary kiln. magnesia bricks are generally used in high temperature zone, anti-stripping alumina brick,silmo brick are used in temperate zone, clay brick is mainly used in low temperature zone. generally inlet and the outlet use corundum mullite, wear-resistant castable, spinel brick,etc. select brick of proper performance, but also take into account the economy

- Q: What is the difference between a clay brick and a red brick?

- Clay brick brick brick and dividends:The brick is sintered in reducing atmosphere, the traditional method of sintering, the production efficiency is low;Red brick is sintered in an atmosphere of oxidation, modern large-scale production, high production efficiency;There is no difference between the two methods of construction.

- Q: 1200 degrees inside the furnace, lay a layer of refractory brick, what is the temperature outside?

- except refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and so on.

- Q: Why is the brick instead of solid clay brick

- Shale is a sedimentary rock weathering hard substance, which is relatively hard, mainly from clay minerals and small clay particles into the pressure, cementation, weathering after the formation of hard substances, such substances are relatively hard.

- Q: How good is the hardness of corundum refractory brick?

- The basic materials of corundum refractories are fused corundum or sintered corundum. the refractory brick containing more than 90% of Al2O3 is called corundum refractory brick. so, corundum refractory brick. Corundum has a high hardness (9 level of Mohs hardness) such as zirconium corundum refractory brick. Corundum refractory brick is resistant to acid well and melting point is also high, also known as pure alumina refractory brick products, , it has a good effect. These are closely related with the structure of the Al - 0 key, titanium corundum refractory brick, and other basic slag. It is used in high temperature oxidizing atmosphere or in reducing atmosphere. the metal and glass solution have good stability. a-Al2O3 is the main material of high temperature refractory brick and high temperature electrical insulating material .

Send your message to us

Fireclay Brick Ceramic Fiber Insulating Blanket

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords