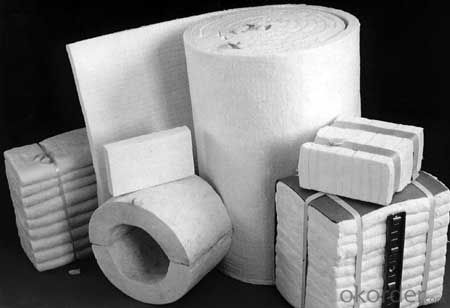

Ceramic Fiber Blanket CE certification thermal insulation ultra-thin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for

CE certification thermal insulation ultra-thin Ceramic Fiber Blanket

| Grade: | HP (High Pure),1260 high-purity cramic fiber blanket | Application: | Liners Of Industrial Furnace | Thickness: | 6-50mm |

| Width: | 100-1220mm | Length: | 21840/14640/7320/4800/3600mm | Chemical Composition: | AL2O3 52-55% AL2O3+SiO2 99% |

| Ultimate Strength (≥ MPa): | 0.5Mpa | Working Temperature: | 0.12 (800℃) 0.20 (1000℃) | Fiber Diameter: | 3-5um |

| Shrinkage (1800 ℉, 3h): | -3% | Density (kg/m³ ): | 128 | Model Number: | ultra-thin ceramic fiber blanket |

| Brand Name: | Place of Origin: | (Mainland) | color: | pure white | |

| samples free: | yes | manufacture or not: | yes | working temparature: | 950℃.1050℃.1100℃.1200℃.1350℃ |

| type: | 1050COM,1260STD.1260HP.1400HA.1450HZ |

Packaging & Delivery

| Packaging Detail: | plastic bag inside and carton or woven bag outside |

| Delivery Detail: | 15 days |

Specifications

1.ultra-thin ceramic fiber blanket

1the ultra-thin 6mm

2 .Energy saving

3 Long service life

Product Description

Cramic Fiber Blanket is a new type of fire-resistant insulation

material ,which can resist corrosion and restore to original thermal and physical properties after drying.It characterise white,tidy, refractory ,heat separation ,thermal insulation function containing no any binding agent and maintaining excellent tensile strength,toughness,fibrous structure when used in a neutral,oxidized atmosphere.

Brief Introduction

Item | ultra-thin ceramic fiber blanket |

Specifications | Density: 64-160kg/m³ ( Regular: 96kg/m³,128kg/m³,160kg/m³ ) |

Width: 100-1220mm | |

Thickness: 6, 13, 19, 25, 38 and 50mm | |

Regular size:21840x610x6mm, 14640x610x12.5mm, 7320x610x25mm, 4800x610x38mm, 3600x610x50mm | |

Types | 1050 COM Ceramic Fiber blanket |

1260 STD Ceramic Fiber Blanket | |

1260 HP Ceramic Fiber Blanket | |

1400 H-ALU Ceramic Fiber blanket | |

1450 Zirconium Ceramic Fiber Blanket | |

Classification Temperature | 1050°C,1260°C ,1400°C, 1450°C |

Characteristic | Excellent chemical stability |

Excellent thermal stability | |

Excellent tensile strength | |

Low thermal conductivity | |

Low heat capacity | |

Excellent insulation properties; | |

Good sound insulation | |

Application | Industrial furnace wall lining; |

Back lining material; | |

Furnace masonry expansion joints, door, roof heat insulation seal; | |

High temperature pipe insulation material; | |

Module / folded module processing material; | |

Fireproof coating. | |

Certification | ISO, CE,REACH,MSDS can be provided |

The third party inspection | BV, TUV, SGS |

Packing: | plastic bags inside and carton or woven bag outside |

Delivery Time | Within 15 days after received the deposit. |

Technical data

types(℃) | 1050Ceramic fiber blanket 1050COM | 1260standard Ceramic fiber blanket 1260STD | 1260high-purity ceramic fiber blanket 1260HP | 1400high- Aluminum ceramic fiber blanket 1400HA | 1450high- zirconium ceramic fiber blanket 1450HZ | |

Operation temperature (℃) | 950℃(1742.F) | 1050℃(1922.F) | 1100℃(2012.F) | 1200℃(2192.F) | 1350℃(2462.F) | |

Density (kg/m3) | 64-120 | |||||

Permanent change on heating (% 24h) | ≤-3 | ≤-3 | ≤-3 | ≤-3 | ≤-3 | |

Theoretic heat conductive co-efficient | 0.15 (600℃) 0.22 (800℃) | 0.12 (600℃) 0.20 (800℃) | 0.12 (600℃) 0.20 (800℃ | 0.12 (600℃) 0.20 (800℃) | 0.16 (800√) 0.20 (1000℃) | |

Tensile strength (Mpa 25mm) | ≥0.04 | ≥0.05 | ≥0.05 | ≥0.04 | ≥0.06 | |

Chemical composition (%)

| AL2O3

| 44 | 45-46 | 47-49 | 52-55 | 39-40 |

AL2O3+SiO2

| ≥96 | ≥98 | ≥99 | ≥99 | - | |

Zro2 | - | - | - | - | 15-17 | |

AL2O3+SiO2+Zro2

| - | - | - | ≥99 | ||

Fe2O3 | ≤10. | ≤0.8 | ≤0.2 | ≤0.2 | ≤0.2 | |

Na2O+k2O | ≤0.4 | ≤0.3 | ≤0.2 | ≤0.2 | ≤0.2 | |

CaO+MgO | ≤0.3 | ≤0.2 | ≤0.2 | ≤00.2 | ≤0.2 | |

| Size of ceramic fiber blanket | ||||||||||

Thickness | Density (kg/m3) | Length | Width | |||

mm | 64 | 96 | 128 | 160 | mm | mm |

6 | - | - | 0 | 0 | 14640 | 610 |

13 | - | 0 | √ | 0 | 14640 | |

19 | - | √ | √ | 0 | 9760 | |

25 | 0 | √ | √ | √ | 7320 | |

38 | 0 | √ | √ | √ | 4880 | |

50 | 0 | √ | √ | - | 3660 | |

Note:0 and 1220mm width can be customized according to customer √ for conventional products | ||||||

- Q: i have really curly hair

- JELLO DESSERT 1 pkg large sugar free jello, any flavor coolwhip fresh fruit Make the jello as on the package but use 1/2 cup less waterAdd fresh fruit like fresh strawberries, grapes, chopped applesLet it gel for 4-6 hoursMix up the jello and add 1/4 tub of cool whipAdd more if desiredMix well, and its like an ambrosiaPut the mix in a glass, and top with more fresh fruit or coolwhipServes 4

- Q: for the last 2 weeks, i have had diarrhea about an hour after eatingno matter what i eatjunk or healthy foodsi have diarrhea about 4 times a daywith stomach pain 5 mins before running to the bathroom.please help mei go to the doctor in a weekbut would like a little light shed on it tho.

- wear a jumper tha maches the scaf

- Q: this is about way back during the industrial revolution in America.1.) how was it used? (i know there was a handle to spin but be specific.)2.) list 3 ways it changed American society.make it sound smart :))

- Yes its ok to put aluminum foil over a cookie sheet and then put it in the oven, I do it all the timeBake as normal.

- Q: does any body know any any websites that sell yarn really,really,really cheap!!!?

- Can you spray the pan with Pam or give it a thin layer of oil? That will help to keep the mozzarella sticks from sticking, and make it easier to clean the pan tooAlso, if you have any parchment paper for baking - that will work.

- Q: I just got a hamster a few months ago, I have been keeping my room warm for him, but it is wearing me out because of the heat in my room I am always getting stuffy noses, and bloody nosesI am use to my room being much colder! My room is currently around 72 degrees, how can i make him warmer, but my room a bit colder?

- The Red Hot Chili Peppers covered more musical ground and did more different thingsLooking at the harmonious indie-esque By The Way, the wild and wacky funk of Freaky Styley, and the fact that they invented rap-rock, the genre in which Rage Against the Machine plays, I can conclude that the Red Hot Chili Peppers are the stronger group, and more influentialThat being said Rage Against is a tight group of some fantastic and dedicated musicians, and I really respect themThe Chili Peppers have simply covered more musical ground and been subject to more critical acclaim.

- Q: My living area consists of one room which is the living room, dining room and kitchenI'd like to cut way down on my electric bill but cannot find any space heaters that will heat a room that sizeIf I use 2 or 3 space heaters, I may be defeating the purposeIn addition, I need a heater for my 10 x 15 bedroom tooLooking for suggestions.

- OKorder is a good place to find bumpsticks

- Q: I Got My Hips Pierced Yesterday.- They Are Surface Piercings.- The Piercer Used Bars That Look Like Navel Rings.- I Use Natural Sea Salt Mixed With Hot Water To Clean Them.- They Itch Sometimes, Which I'm Assuming Means They're Healing.My Concerns: - Is The Bar He Used Normal? He Said It Standard, But I Wanna Double Check.- What Are The Risks Of Rejection? I've Heard Things from 50-85%.- Am I Cleaning them Right? I Think I Am, But Double Checking.- At What Point in The Healing Process Can I Start Training Them To Fall A Certain Way?- What Else Can I Do To Prevent Rejection?- Is It Better To Keep Them Covered Or Uncovered During The Day?- Should I Bandage Them When I Go To Sleep At Night?ANYTHING Else You Can Tell Me Will Help And Be Greatly Appreciated.

- You can drill out the old ones with a drill bit no larger than the original rivet shank, but you may have to go up one size for your replacement rivets should the old hole(s) be deformedUse blind rivets - and marine rated at that if at all possible if replacing the smaller typesRivet blanks for the bigger may be available from airframe suppliers if you cannot get them from the maker of your hull, these need to be peened, and may require load washersIn all cases used Dura-Lac or a similar anti-corrosive bedding compound generously, two coats - the first to all contact surfaces and allow to dry, then apply a second coat and fasten/peen while wetThis will largely eliminate electrolysis and other hidden corrosion issues within the joint for a long timeRivets are structural membersand must be replaced like for like to maintain the integrity of any structure so designed.

- Q: What does it mean when knitting slippers to use 2 strands of 4-ply worsted weight yarn?

- Be careful with naval architectureYour career will likely require you to live near a shipyardSo what? Investigate how those areas look for raising kidsCivil and Mechanical fields are to big to evaluateBoth include dozens of areas from designing semi-truck piston heads to cell phone belt hooks.

- Q: Trying to get as full as possible on the least amount of calories for the lowest priceDoesnt have to be tasteless, thats just something people want for fiber powders b/c otherwise it gets gooeyI need 35 gms fiber per day and the bars I get are 14 gm each but high sugar and expensiveI have to eat 2 a day.not always feasible.If you can recommend a powder (they seem to be the lowest calories from all supplement choices) that fits this profile, I'd really appreciate it!!!! :):) thx.

- as i recall the protein shakes from gnc have 150 calories or even less and are high in protein , there is the low carb slim fast as wellto gain muscle you need some carbs and fat as well because if you don't have enough energy your body will burn muscle to get fuelthe good news is that muscle burns energy even when you're restingwhat you can do is eat a fat free yogurt or drink skim milk it contains carbs , protein and calcium, all good for getting enough muscleto get fiber add some frozen berries to the yoghurt and sweeten it with splenda to get a healthy smoothienuts are very healthy toodon't try to gain muscle on the expense of your healthi used to eat salmon as well to get enough protein and keep my skin looking good, fish is high in protein and low in calories, you can cook it with herbs to make it taste betterprotein bars/shakes aren't the only source of protein, and adding a salad filled with greens with every meal will get you a lot of fiberdon't forget that with all the protein and fiber you have to drink a lot of water to avoid dehydrationgood luck!

Send your message to us

Ceramic Fiber Blanket CE certification thermal insulation ultra-thin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords