Carbon Steel Universal Beam in I Shaped Form Chinese Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Carbon Steel Universal Beam in I Shaped Form Description:

Carbon steel universal beam in I shaped form is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Carbon steel universal beam in I shaped form is usually made of structural steel and is used in construction and civil engineering. The carbon steel universal beam in I shaped form resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Carbon steel universal beam in I shaped form theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam Bar IPE Images:

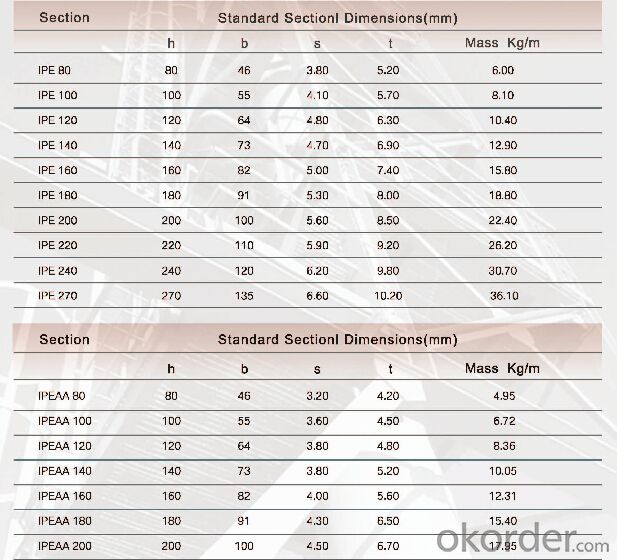

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How do Steel I-Beams compare to wood beams in terms of strength?

- Steel I-beams are significantly stronger than wood beams in terms of strength. The structural properties of steel, including its high tensile strength, make it an ideal material for supporting heavy loads and withstanding extreme forces. Steel I-beams are designed to distribute weight evenly, making them capable of handling much larger loads than wood beams. Wood beams, on the other hand, have a lower strength-to-weight ratio and are more prone to bending and warping over time. While wood beams can be sufficient for certain applications, steel I-beams provide a superior level of strength and reliability, particularly in construction projects where heavy loads or long spans are involved.

- Q: Can steel I-beams be used for underground structures or tunnels?

- Yes, steel I-beams can be used for underground structures or tunnels. Steel is a popular choice for underground construction due to its strength, durability, and resistance to corrosion. Steel I-beams provide structural support and are commonly used in the construction of underground structures such as tunnels, subway systems, underground parking lots, and underground storage facilities. They can withstand heavy loads and provide stability in underground environments. Additionally, steel I-beams can be easily fabricated and customized to meet specific design requirements, making them a versatile choice for underground construction projects.

- Q: What are the different surface finishes available for steel I-beams?

- There are several different surface finishes available for steel I-beams, each serving a specific purpose and providing unique benefits. The most common surface finishes for steel I-beams include: 1. Mill Finish: This is the most basic and common surface finish for steel I-beams. It refers to the raw, untreated surface of the steel beam as it comes from the mill. Mill finish is typically characterized by a dull gray appearance and may have some minor imperfections or blemishes. It is suitable for applications where aesthetics and corrosion resistance are not major concerns. 2. Hot-dip galvanized: Hot-dip galvanizing involves immersing the steel beam in a molten zinc bath, which forms a protective coating on the surface. This finish offers excellent corrosion resistance, as the zinc coating acts as a barrier against moisture and other corrosive elements. Hot-dip galvanized steel I-beams are commonly used in outdoor applications or environments where exposure to harsh weather or corrosive substances is expected. 3. Painted: Steel I-beams can also be finished with paint coatings. The paint serves as a protective layer that helps to prevent corrosion and enhance the beam's appearance. Painted finishes provide a wide range of color options and can be customized to match specific aesthetic requirements. This finish is commonly used in architectural and decorative applications where the appearance is important. 4. Powder-coated: Powder coating is a dry finishing process in which a powdered coating material is applied electrostatically to the steel beam and then cured under heat. This process results in a durable, smooth, and uniform finish that provides excellent corrosion resistance and can be customized in terms of color and texture. Powder-coated steel I-beams are often used in indoor and outdoor applications that require both durability and aesthetics. 5. Black oxide: Black oxide is a chemical conversion coating that forms a thin, black oxide layer on the steel beam's surface. This finish provides mild corrosion resistance and enhances the beam's appearance by providing a dark, black color. Black oxide finishes are commonly used in applications where a sleek and uniform appearance is desired, such as architectural or decorative elements. In summary, the different surface finishes available for steel I-beams include mill finish, hot-dip galvanized, painted, powder-coated, and black oxide. Each finish offers unique benefits in terms of corrosion resistance, aesthetics, and suitability for specific applications. The choice of surface finish depends on factors such as the intended use, environmental conditions, and desired appearance.

- Q: Can steel I-beams be used for cryogenic applications?

- Indeed, cryogenic applications can make use of steel I-beams. The remarkable strength and durability of steel render it a fitting choice for a multitude of industrial uses, including those in cryogenic settings. Nonetheless, it is crucial to exercise caution when selecting the precise variant of steel to guarantee its aptitude in enduring the extreme temperatures and potential brittleness that can manifest under cryogenic circumstances. Moreover, it is imperative to consider adequate insulation and design factors in order to reduce heat transfer and avert thermal strain on the steel beams.

- Q: Are steel I-beams resistant to chemical exposure?

- Steel I-beams are generally resistant to chemical exposure. However, the level of resistance may vary depending on the specific chemical involved, its concentration, and the duration of exposure. It is important to consult with experts or refer to chemical compatibility charts to ensure proper protection and maintenance of steel I-beams in corrosive environments.

- Q: How do steel I-beams perform in terms of sustainability and recyclability?

- Steel I-beams are materials that are highly sustainable and recyclable. When it comes to sustainability, construction projects often prefer steel I-beams because of their durability and long lifespan. They can withstand heavy loads and resist deformation, meaning they require less maintenance and replacement as time goes on. This reduces the need for additional resources and energy consumption for repairs or replacements, making them a sustainable option. Moreover, steel I-beams have a lower carbon footprint compared to other building materials. Steel is made from iron ore, which is one of the most abundant resources on Earth, and it can be manufactured using energy-efficient processes. Additionally, steel is highly energy-efficient when used in buildings, as it can help regulate temperature and reduce the need for excessive heating or cooling. Recyclability is another significant aspect of steel I-beams. Steel is one of the few materials that can be recycled indefinitely without losing its quality or strength. At the end of a building's life cycle, steel I-beams can be easily salvaged, melted down, and reprocessed to create new steel products. This reduces the demand for new materials, conserves energy, and minimizes waste sent to landfills. The recyclability of steel I-beams also contributes to the circular economy, where materials are continuously reused instead of being thrown away. This not only reduces the environmental impact but also saves costs associated with extracting and producing new materials. To sum up, steel I-beams are highly sustainable and recyclable. Their durability, low carbon footprint, and ability to be recycled indefinitely make them an environmentally responsible choice for construction projects. By choosing steel I-beams, we can contribute to a more sustainable and circular economy.

- Q: Can steel I-beams be used for historical preservation projects?

- Yes, steel I-beams can be used for historical preservation projects. While traditional building materials like wood or stone are often associated with historical structures, steel I-beams have become a common choice due to their durability, strength, and versatility. Steel I-beams are well-suited for supporting heavy loads and can be customized to fit various architectural designs. In historical preservation projects, steel I-beams are typically used to reinforce and stabilize existing structures. They can be installed discreetly within the building to provide structural support without compromising the aesthetic or historical integrity. Additionally, steel I-beams can be used to replace deteriorated or damaged wooden or stone beams, ensuring the safety and longevity of the structure. One advantage of using steel I-beams in historical preservation is their resistance to environmental factors such as moisture, pests, and fire. These beams are typically treated to prevent corrosion, making them ideal for withstanding the test of time. Moreover, steel is a sustainable and recyclable material, aligning with modern conservation practices. However, it is crucial to strike a balance between preserving historical authenticity and incorporating modern materials. In some cases, the use of steel I-beams may be limited to sections that are not visible or can be concealed, as the visual impact of these beams may not align with the original architectural style. A thorough assessment and consultation with preservation experts are necessary to ensure that the use of steel I-beams respects the historical value of the structure while providing the necessary structural support. Overall, steel I-beams can play a vital role in historical preservation projects by enhancing the stability and longevity of structures while maintaining their original aesthetic appeal. With proper planning and execution, these beams can successfully contribute to the preservation of historical buildings for generations to come.

- Q: It's not clear what difference between I-beam and channel steel What's the difference between the formulas for the two materials?

- I-beam, also called steel girder, is a long strip steel with cross section. Wing to the edge of the root cause of I-beam thinning, have a certain angle,I type is Arabia digital cm with its waist high number to represent, web and flange thickness and flange width of different specifications to the waist high (H) * (b) * waist leg width thickness (T). The number of said, such as "160 x 88 x 6", that is 160 mm high waist, leg width is 88 mm, 6 mm thick steel waist. The specifications of I-beam can also be expressed by type. The model indicates the height of centimeters, such as 16#. The same as the waist high beam, there are several different leg width and waist thick, B C to make a difference in the model to the right a, such as 32a# 32b# 32c#. Ordinary I-beam and light steel I-beam, ordinary hot rolled I-beam specifications for 10-63#. Standard Specification for hot-rolled ordinary I-beam supplied by supply and demand agreement is 12-55#. I-beam is widely used in various building structures, bridges, vehicles, supports, machinery and so on.

- Q: What are the challenges in transporting and handling steel I-beams?

- Transporting and handling steel I-beams presents several difficulties stemming from their size, weight, and shape. Firstly, the sheer weight of these beams can make transportation a challenging task. Depending on their length and size, they can weigh several tons, necessitating the use of specialized equipment like cranes, forklifts, or heavy-duty flatbed trucks with lifting capabilities. The size and shape of I-beams also pose maneuverability challenges. Their long and narrow structure can make navigation through tight corners or narrow spaces difficult, especially in urban areas or construction sites with limited access. This requires careful planning and coordination to ensure safe transportation and prevent damage to the beams or surrounding structures. Another obstacle in handling steel I-beams is their vulnerability to damage. Given their frequent use in construction projects, any damage during transportation can compromise their structural integrity, leading to safety hazards and costly repairs. It is crucial to protect the beams from impacts, shifting, sliding, and exposure to adverse weather conditions such as rain, snow, or extreme temperatures. Additionally, skilled labor and specialized knowledge are necessary for the proper handling of steel I-beams. Adequate training and expertise are essential to safely load, unload, and securely fasten the beams during transportation. Improper handling techniques not only risk damaging the beams but also pose serious threats to the workers involved. Lastly, the cost of transporting and handling steel I-beams can be a significant obstacle. The need for special equipment and transportation methods, due to their weight and size, incurs substantial expenses. Moreover, factors like fuel costs, permits, and escorts can further contribute to the overall costs. In conclusion, the challenges associated with transporting and handling steel I-beams encompass their weight, size, shape, susceptibility to damage, and the requirement for skilled labor and specialized equipment. Proper planning, coordination, and adherence to safety protocols are vital to overcome these challenges and ensure successful transportation and handling of steel I-beams.

- Q: How do steel I-beams contribute to the overall sustainability of a renovation project?

- There are several ways in which a renovation project benefits from the inclusion of steel I-beams, ultimately enhancing overall sustainability. To begin with, steel is an incredibly eco-friendly material for construction. It stands out as one of the most environmentally conscious options available due to its high recyclability. In fact, manufacturing steel from recycled sources consumes notably less energy compared to producing it from raw materials. By incorporating steel I-beams into a renovation project, the demand for new steel production is reduced, resulting in a minimized carbon footprint. Moreover, steel I-beams provide exceptional strength and durability, allowing for efficient structural designs. As a result, fewer materials are necessary to support the load, leading to reduced overall material consumption. The utilization of steel I-beams thus enables a renovation project to achieve the desired structural integrity while minimizing material waste. Additionally, steel is renowned for its longevity and resistance to deterioration. Properly maintained steel I-beams have an extremely low risk of rotting, warping, or being attacked by pests, which are common issues encountered in renovation projects involving alternative materials like wood. This longevity ensures that the renovation will have a lasting impact, diminishing the need for future repairs or replacements. Lastly, steel I-beams offer flexibility in both design and construction. Their lightweight nature facilitates easier transportation and installation, ultimately reducing energy consumption throughout the construction process. Furthermore, steel structures can be easily modified or expanded in the future, providing adaptability to changing needs and minimizing the necessity for additional construction. In conclusion, the inclusion of steel I-beams significantly contributes to the overall sustainability of a renovation project. Their recyclability, strength, durability, and flexibility all play pivotal roles in reducing environmental impact, minimizing waste, and ensuring long-term sustainability.

Send your message to us

Carbon Steel Universal Beam in I Shaped Form Chinese Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords