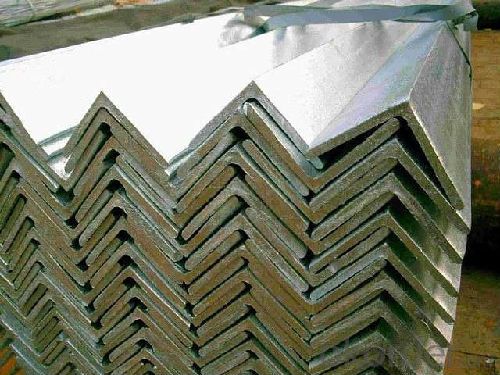

Chinese Standard Hot Rolled Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Chinese Standard Hot Rolled Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Chinese Standard Hot Rolled Angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Chinese Standard Hot Rolled Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel I-beams perform in earthquake-prone regions?

- Steel I-beams have gained recognition for their exceptional performance in regions susceptible to earthquakes. The combination of steel's structural properties and the unique design of the I-beams make them highly resilient to seismic activity. The strength and ductility of steel I-beams are key advantages. Steel is a remarkably robust material capable of withstanding significant forces and loads. When an earthquake occurs and the ground shakes, generating powerful seismic waves, steel I-beams possess the ability to flex and absorb the energy. This flexibility prevents the beams from breaking or collapsing under the intense vibrations, thus ensuring the overall stability of the structure. Furthermore, the shape of the I-beams plays a critical role in their earthquake performance. The I-shaped cross-section provides greater resistance to bending moments and shear forces, rendering them less vulnerable to the lateral forces generated by earthquakes. This shape allows the beams to distribute seismic forces more efficiently, reducing the likelihood of structural damage. In addition to their strength and shape, steel I-beams offer the advantage of being lightweight compared to other building materials. This characteristic is particularly advantageous in earthquake-prone regions as it reduces the mass of the structure. A lighter building has lower inertia, resulting in less movement during an earthquake. Consequently, this significantly decreases structural stresses and minimizes the risk of damage or collapse. Moreover, steel I-beams can be designed and constructed to meet the strict building codes and regulations specific to earthquake-prone regions. These codes often require the use of materials and construction techniques that enhance the resilience of the structure during seismic events. Steel I-beams can easily fulfill these requirements, making them a favored choice for earthquake-resistant construction. In conclusion, steel I-beams have demonstrated their remarkable effectiveness in earthquake-prone regions. Their strength, ductility, shape, and lightweight nature contribute to their outstanding performance during seismic events. By providing flexibility, efficient force distribution, and compliance with rigorous building codes, steel I-beams ensure the safety and stability of structures in areas prone to earthquakes.

- Q: Can steel I-beams be used as columns or posts in construction?

- Indeed, steel I-beams have the potential to serve as columns or posts within construction projects. Their exceptional strength and capacity to bear heavy loads have made them extensively utilized in the construction industry. Employed as columns or posts, they effectively uphold substantial weights and ensure structural stability. Renowned for their resilience and resistance against bending or warping, steel I-beams prove themselves fitting for diverse construction endeavors. Moreover, they offer the convenience of customization to accommodate specific design specifications and can be manufactured in various dimensions and lengths.

- Q: How many meters is I-beam one?

- I-beam is also called steel girder (English name Universal Beam). It is a strip of steel with an I-shaped section. I-beam is divided into ordinary I-beam and light I-beam, H steel three. It is a section steel whose shape is trough.

- Q: Are there any special considerations when designing with steel I-beams for long-span structures?

- Yes, there are several special considerations when designing with steel I-beams for long-span structures. Firstly, the deflection and stability of the beams must be carefully analyzed to ensure they can support the loads without sagging or buckling. Additionally, the connection details between the beams and other structural elements need to be meticulously designed to provide adequate strength and ensure proper load transfer. Furthermore, the potential for vibrations and dynamic loads must be taken into account to prevent any potential resonance issues. Lastly, the fabrication, transportation, and erection of the long-span steel beams should be carefully planned to ensure feasibility and cost-effectiveness.

- Q: How do steel I-beams compare to timber beams in terms of strength?

- Steel I-beams are generally stronger than timber beams in terms of strength. Steel has a much higher strength-to-weight ratio compared to timber, allowing steel I-beams to support greater loads without sagging or bending. Additionally, steel is more resistant to compression, tension, and bending forces, making it a more reliable choice for structural support. Timber beams, on the other hand, can be prone to warping, splitting, and decay over time, which can compromise their strength. However, it is important to note that the strength of steel I-beams can vary depending on the specific grade and size of the beam, while timber beams can be reinforced with additional members or materials to enhance their strength.

- Q: What are the common finishes for steel I-beams?

- There are various finishes available for steel I-beams, including hot-dip galvanizing, priming and painting, and powder coating. Hot-dip galvanizing is a method that involves coating the steel I-beam with zinc, which protects it against corrosion and ensures its durability. This finish is commonly used in outdoor applications where the I-beam will be exposed to moisture or harsh environmental conditions. Another option is priming and painting, which entails applying a layer of primer to the surface of the I-beam to enhance adhesion, followed by one or more coats of paint. This not only provides a protective barrier against corrosion but also allows for customization in terms of color and appearance. Powder coating is a different finish that entails electrostatically applying a dry powder onto the I-beam's surface. The powder is then cured under heat, resulting in a strong and long-lasting finish. Powder coating offers excellent corrosion resistance, as well as a wide range of color options and a smooth, even appearance. It is important to consider the specific requirements of the application when choosing a finish for steel I-beams. Factors such as the environment, aesthetic preferences, and level of corrosion resistance needed should all be taken into account.

- Q: What are the common methods of protecting steel I-beams from fire damage?

- There are several common methods of protecting steel I-beams from fire damage. 1. Fire-resistant coatings: Applying fire-resistant coatings to the surface of steel I-beams is one of the most common methods. These coatings are designed to provide a protective layer that can withstand high temperatures and prevent the steel from reaching its critical temperature. Fire-resistant coatings can be either intumescent (expand when exposed to heat) or ablative (form a charred layer to insulate the steel). 2. Fireproofing materials: Another method is to encase the steel I-beams with fireproofing materials such as concrete or gypsum board. These materials act as a barrier, preventing the heat from reaching the steel and maintaining its structural integrity during a fire. Fireproofing materials can be applied as a spray or as pre-formed boards. 3. Fire-resistant insulation: Insulating the surrounding areas of steel I-beams with fire-resistant materials is also a common method. The insulation materials, such as mineral wool or ceramic fiber, help to reduce heat transfer and protect the steel from fire damage. This method is particularly useful when there is limited space to apply coatings or fireproofing materials directly on the beams. 4. Structural protection: In some cases, the structural design of a building may include additional measures to protect steel I-beams from fire damage. This can include the use of fire-resistant partitions or barriers to compartmentalize the building, limiting the spread of fire and protecting the beams in affected areas. It is important to note that the choice of protection method depends on various factors such as the fire rating requirements, building codes, and the specific application of the steel I-beams. It is recommended to consult with fire protection experts or engineers to determine the most suitable method for each particular situation.

- Q: I took 20 overhanging scaffolding difficult to take the highest. How many meters height

- Cantilevered scaffold generally has two kinds: one kind is each layer of a pick, the vertical rod at the bottom of the top in the construction site, floor beam or wall, outward tilt after fixed on the upper part of the erection of scaffolding construction, rail laying layer, construction of a story, to be transferred to the upper layer, and then re ride scaffold provides a layer of construction; the other is the multilayer cantilever scaffold, the full height is divided into several sections, each section of the erection of a height of not more than 20m, the use of cantilever beam or cantilever frame for scaffold based subsection overhanging scaffolding section, this method can use scaffolding over 50m above.

- Q: What are the typical connection methods for steel I-beams?

- The typical connection methods for steel I-beams include welding, bolting, and riveting. Welding is a common method where the beams are fused together using heat, creating a strong and continuous connection. Bolting involves using bolts and nuts to fasten the beams together, providing a secure connection that can be easily disassembled if needed. Riveting is another method where metal pins called rivets are used to join the beams by passing them through pre-drilled holes and then hammering them to create a permanent connection. These connection methods ensure the stability and structural integrity of steel I-beams in various applications.

- Q: Can steel I-beams be used in residential renovations or additions?

- Yes, steel I-beams can be used in residential renovations or additions. They are commonly used in construction projects to provide structural support and are particularly beneficial when spanning long distances or supporting heavy loads. Steel I-beams offer strength, durability, and versatility, making them suitable for various residential applications such as creating open floor plans, removing load-bearing walls, or adding additional stories to existing homes.

Send your message to us

Chinese Standard Hot Rolled Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches