Cold Rolled Steel Coil SPCC DC01 SPHC DC02

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, BS, GB, JIS | Thickness: | 0.3-1.8mm | Place of Origin: | Hebei, China (Mainland) |

| Brand Name: | CNBM | Model Number: | cold rolled steel coils | Type: | Steel Plate |

| Technique: | Cold Rolled | Surface Treatment: | Coated, Bright finish, Plating | Application: | building and constructions |

| Special Use: | High-strength Steel Plate | Width: | 1250, 600-1250mm | Length: | as required |

| Coil ID: | 508/610mm | Grade: | Q195~Q345,SPCC/SPCD/DC01 | Coil weight: | 3-12 MT |

| Zinc Coating: | 30-275g/ m2 |

Packaging & Delivery

| Packaging Details: | Standard export seaworthy package |

| Delivery Detail: | Within 20 days after received the prepaid |

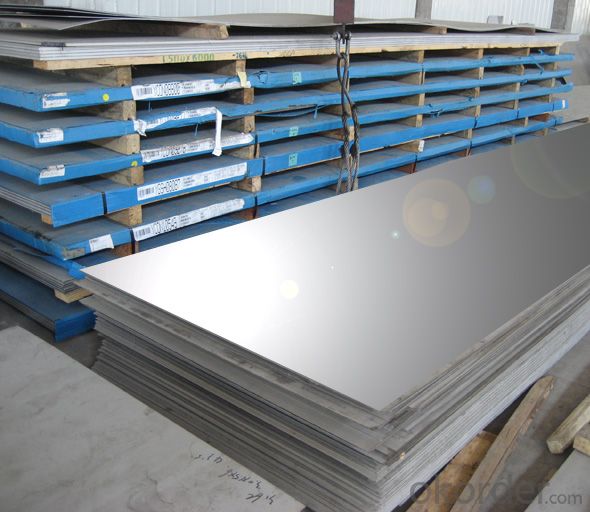

SPCC SPCD SPCE Cold rolled steel coil/sheet

Product details

| 1,product name | SPCD Cold rolled steel coil/sheet |

| 2,Standard | AISI,ASTM,BS,DIN,GB,JIS |

| 3,Executive standards | Q/HB04-2008(Cold Rolled Sheets and Strips) |

| 4,Inspection | ISO/BV/SGS |

| 5,certification | ISO9001 |

6,material | Q235B, Q345B, SPHC, SPHD,SPHE,510L , Q345A,Q345E |

7,steel grade | SPCC, SPCD, ST12, ST13, ST14/16, DC01, DC02, DC03, DC04, DC05, DC06, |

8,thickness | 0.16-3.5mm |

9,width | 900-1450mm |

10,surface treatment | coated&galvanized&bright/black annealed/unoil |

11,packing | Standard export packing or according to the clients required |

12,coil weight | 5-10tons |

13,Coil inner diameter | 508/610mm |

14,coil outer diameter | Max.Φ1500 or as your request |

15,usage/main application | transportation machine,Container Plate,chemical,building industry,automobile |

| 16,Product Category | galvanized,coated,spcc,spcd,spce,etc |

| 17, Spangle State | regular spangle, small spangle, big spangle, non-spangle |

| 18,Product Feature | High Surface Finish; Uniform coating thickness; High tensile strength(>600); Excellent atmospheric corrosion resistance,welding and cold forming performance; Leaf-shaped crystalline pattern; Beautiful Designed |

- Q:I need help! Please help, I'm in Chemistry, and me and my friend Lucy are making a presentation on steel and iron, so how is steel manufactured? Thank you. :D

- The steel consists of ( Iron ) and another matter... but the popular one is iron+carbon / iron+silver - When iron is smelted from its ore by commercial processes, it contains more carbon than is desirable. To become steel, it must be melted and reprocessed to reduce the carbon to the correct amount, at which point other elements can be added. This liquid is then continuously cast into long slabs or cast into ingots. Approximately 96% of steel is continuously cast, while only 4% is produced as cast steel ingots. The ingots are then heated in a soaking pit and hot rolled into slabs, blooms, or billets. Slabs are hot or cold rolled into sheet metal or plates. Billets are hot or cold rolled into bars, rods, and wire. Blooms are hot or cold rolled into structural steel, such as I-beams and rails. In modern foundries these processes often occur in one assembly line, with ore coming in and finished steel coming out. Sometimes after a steel's final rolling it is heat treated for strength, however this is relatively rare.

- Q:How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts by being unwound and fed into a machine that cuts and shapes them into the desired bolt size and shape. The coils provide a continuous and uniform supply of steel, ensuring consistent quality and efficiency in bolt production.

- Q:How do you calculate the weight of a steel coil?

- In order to determine the weight of a steel coil, one must have knowledge of its dimensions and the specific gravity of the steel. The weight can be calculated using the following formula: Weight of steel coil = Length of coil (in meters) x Width of coil (in meters) x Thickness of coil (in meters) x Specific gravity of steel To begin, measure the length, width, and thickness of the steel coil in meters. It is important to ensure that all measurements are in the same unit in order to obtain accurate calculations. Next, find the specific gravity of the steel. The specific gravity is the ratio of the density of the substance to the density of water. For steel, the specific gravity is typically around 7.8. Multiply the length, width, and thickness of the coil together. This calculation will provide the volume of the steel coil in cubic meters. Lastly, multiply the volume of the coil by the specific gravity of steel to obtain the weight of the steel coil in kilograms (kg). Please note that this calculation only accounts for the weight of the steel coil and does not consider any additional factors such as the core material or any other components included in the coil.

- Q:Why is the selection of steel building erector of extreme importance while starting a new steel building project?

- Steel building erectors play an important role as they are well versed with all the ups and downs of erecting a steel building and can prevent your construction project from unnecessary delays. There are lot of inexperienced steel building erectors in the market who can offer you their services at a much cheaper rate. Be cautious! It never works in the long run. A qualified steel building erector will always provide an initial professional insight of your project and cost effective solutions for your project.

- Q:I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- In that video, he is using a steel-string acoustic guitar. However, when choosing between a nylon string guitar and a steel string guitar, you must consider a few things. Steel-string guitars are more painful in the beginning for the fretting hand, but that means you'll have more strength in your fingers faster. Nylon-string guitars are easier on the fingers and sound much smoother and calmer than steel-string guitars. Also, nylon-string guitars have a wider neck and that neck meets the body at the twelfth fret, while most steel-string guitars have a thinner neck that meets the body at the fourteenth fret. Have fun with your first guitar! :)

- Q:How do steel coils contribute to the energy sector?

- Various contributions are made by steel coils to the energy sector. Firstly, they play a crucial role in the manufacturing of essential equipment and infrastructure for energy production and distribution. Examples include power plants, transmission towers, and pipelines. These structures necessitate robust and durable materials, which are provided by steel coils, ensuring the required strength and reliability. Additionally, steel coils have a significant impact on the renewable energy sector. They are utilized in the production of wind turbines and solar panels. For wind turbines, steel coils are necessary for constructing the towers, while solar panels rely on steel frames for support and durability. With the increasing demand for renewable energy sources, the utilization of steel coils in this sector is expected to rise correspondingly. Moreover, steel coils are integral in the manufacturing of electrical transformers. Transformers are vital components in the energy sector as they facilitate the transmission and distribution of electricity. The core of the transformer, responsible for efficient energy transfer, is created using steel coils. The quality and dependability of the steel coils used in transformers are crucial to ensure the smooth functioning of the electrical grid. In addition to their direct applications, steel coils also indirectly contribute to the energy sector. Steel is a recyclable material, and the recycling process consumes less energy compared to the production of new steel. By employing recycled steel coils, the energy sector can decrease its carbon footprint and contribute to a more sustainable and environmentally friendly energy production process. In summary, steel coils are an indispensable component in the energy sector. They are utilized in manufacturing equipment and infrastructure, including power plants, transmission towers, wind turbines, solar panels, and electrical transformers. Furthermore, the recyclability of steel enhances the sustainability of the energy sector.

- Q:What is the average surface finish tolerance for steel coils?

- The average surface finish tolerance for steel coils can vary depending on the specific requirements and standards set by the industry or customer. Generally, it ranges from 10 to 20 micro-inches (0.25 to 0.5 micrometers), but it is important to consult the relevant specifications for the specific application.

- Q:I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

- Q:Can steel coils be used in the food processing industry?

- Indeed, the food processing industry can utilize steel coils. These coils frequently serve as the foundation for a diverse array of food processing equipment, including conveyor belts, food storage tanks, mixing tanks, and processing machinery. Steel, characterized by its durability and hygienic properties, possesses resistance against corrosion, rendering it appropriate for deployment in food processing environments. Furthermore, steel coils facilitate effortless cleaning and sanitization, guaranteeing the safety and cleanliness of the food processing equipment. In conclusion, owing to their robustness, longevity, and adherence to food safety regulations, steel coils enjoy widespread employment within the food processing industry.

- Q:How are steel coils classified based on their thickness?

- Steel coils are classified based on their thickness using a gauge system, where the higher the gauge number, the thinner the coil.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Steel Coil SPCC DC01 SPHC DC02

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords