Galvanized Hexagonal Wire Netting Before Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

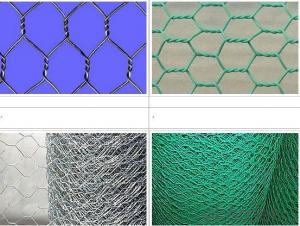

Pictures of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Can steel wire mesh be used for creating decorative ceilings or screens?

- Certainly, decorative ceilings or screens can indeed be created using steel wire mesh. This material, known for its versatility, can be easily manipulated and shaped into various designs and patterns, resulting in visually appealing and distinctive ceilings or screens that bring a modern and contemporary touch to any space. One of the advantages of utilizing steel wire mesh for decorative purposes lies in its durability. This material boasts strength and resistance to wear, making it suitable for long-lasting installations. It can endure different environmental conditions without being easily affected by moisture or temperature changes. Moreover, steel wire mesh offers a wide array of design possibilities. It can be woven or knitted into different patterns, enabling the creation of intricate and captivating designs. Additionally, specific aesthetic effects, such as increased transparency or color variations, can be achieved by applying different wire thicknesses and coatings. Additionally, steel wire mesh is a favored option for crafting screens or dividers within a given area. It can partition spaces while maintaining an open and airy atmosphere. The mesh's transparency allows for the passage of light and air, contributing to a sense of openness and connectivity. In conclusion, steel wire mesh is an outstanding option for fashioning decorative ceilings or screens. Its durability, versatility, and aesthetic possibilities have made it a sought-after material for architects, designers, and homeowners seeking to infuse their spaces with a modern and distinctive touch.

- Q:Can steel wire mesh be fire resistant?

- Steel wire mesh is capable of being fire resistant. Steel itself is a material that does not catch fire or contribute to the spread of flames. When used in the form of wire mesh, the steel strands are typically woven or welded together in a manner that creates small openings between the wires, allowing for the circulation of air. This particular design aids in dissipating heat and preventing the accumulation of intense heat in a single area, thereby reducing the likelihood of ignition or melting. Moreover, certain steel wire mesh products are coated with fire-resistant coatings or treated with fire retardant chemicals to enhance their fire resistance properties. These coatings or treatments serve to delay the spread of flames and offer additional protection against fire. Nonetheless, it is crucial to acknowledge that the fire resistance of steel wire mesh may vary based on factors such as the specific type of steel used, the construction method employed, and any additional fire-resistant treatments administered to the mesh. Thus, it is advisable to consult manufacturers or fire safety professionals in order to ensure that the steel wire mesh complies with the necessary fire resistance standards for a given application.

- Q:Is steel wire mesh resistant to extreme weather conditions?

- Yes, steel wire mesh is generally resistant to extreme weather conditions. Steel wire mesh is made from high-quality steel, which makes it strong and durable. It can withstand harsh environmental conditions such as heavy rain, strong winds, and extreme temperatures. The steel construction of the mesh also ensures that it does not warp or lose its shape under stress. This makes it an ideal material for outdoor applications where it is exposed to extreme weather conditions. However, it is important to note that the level of resistance may vary depending on the specific grade and quality of steel used in the mesh. Additionally, proper installation and maintenance of the mesh are also crucial to ensure its long-term durability and resistance to extreme weather conditions.

- Q:What are the different mesh patterns available for steel wire mesh?

- There are several different mesh patterns available for steel wire mesh, each designed to serve specific purposes and applications. Some of the common mesh patterns include: 1. Square Mesh: This is the most basic and commonly used mesh pattern, consisting of wires woven in a simple crisscross pattern to form square openings. It is versatile and suitable for a wide range of applications, including fencing, screening, and filtration. 2. Rectangular Mesh: Similar to square mesh, but with rectangular openings instead. This pattern is often preferred when a more elongated opening is required, such as in architectural applications or for separation of materials based on size. 3. Dutch Weave Mesh: In this pattern, the warp wires are densely woven together while the weft wires are woven more openly. This creates a tight and strong mesh with finer openings, making it ideal for precision filtration, separation, and sieving applications. 4. Twilled Weave Mesh: Twilled weave mesh is characterized by diagonal patterns created by the weaving of wires. This pattern provides a higher degree of strength and durability compared to plain weave mesh, making it suitable for heavy-duty applications such as industrial screens and conveyor belts. 5. Welded Mesh: Unlike woven mesh patterns, welded mesh is made by welding intersecting wires together at their junctions. This results in a strong and rigid mesh with uniform openings, making it suitable for applications where high strength and rigidity are required, such as security fencing or reinforcement in concrete structures. 6. Expanded Metal Mesh: This pattern is created by simultaneously slitting and stretching a metal sheet, resulting in a mesh with diamond-shaped openings. Expanded metal mesh offers excellent strength-to-weight ratio, good ventilation, and anti-slip properties, making it suitable for walkways, platforms, and filtration applications. 7. Crimped Mesh: Crimped mesh is created by weaving wires with crimped or corrugated profiles, resulting in a mesh with a wavy pattern. This pattern provides better stability and increased rigidity compared to plain weave mesh, making it suitable for architectural applications, decorative purposes, and particle classification. These are just some of the common mesh patterns available for steel wire mesh. The choice of pattern depends on the specific requirements of the application, such as desired opening size, strength, rigidity, and aesthetics.

- Q:Is steel wire mesh corrosion-resistant?

- Yes, steel wire mesh is generally corrosion-resistant.

- Q:Can steel wire mesh be used for reinforcing plaster and stucco?

- Yes, steel wire mesh can indeed be used for reinforcing plaster and stucco. The mesh provides added strength and stability to the plaster or stucco, preventing cracking and ensuring its durability over time. The mesh is typically embedded in the base coat of plaster or stucco and acts as a reinforcement, helping to distribute the forces and stresses that may occur on the surface. It also helps to minimize shrinkage and increase the resistance to impact and other external forces. Overall, steel wire mesh is a commonly used material for reinforcing plaster and stucco due to its strength, flexibility, and ability to enhance the performance and longevity of these finishes.

- Q:How does the color affect the visibility of steel wire mesh?

- The visibility of steel wire mesh can be affected by its color, although it is not the main factor. The primary factors that determine the visibility of steel wire mesh are its size, pattern, and the environment in which it is placed. However, the color can still play a secondary role in determining how visible the mesh is. In general, lighter colors like silver or white make steel wire mesh more visible in darker environments. This is because lighter colors reflect more light, making the mesh stand out against its surroundings. On the other hand, darker colors like black or dark gray can make the mesh blend in more easily in low light conditions or when placed against dark backgrounds. It is important to note, however, that color alone does not determine the visibility of steel wire mesh. The mesh size and pattern, as well as the lighting conditions and background against which it is placed, have a greater impact on its visibility. For example, a larger mesh size with a distinct pattern will be more visible regardless of its color. Moreover, in certain specific applications such as security fencing or architectural purposes, the color of steel wire mesh may be chosen to blend in with the surrounding environment or match the overall aesthetic. In these cases, visibility may not be the primary concern, and other factors such as durability or design may take precedence. To summarize, while the color of steel wire mesh can have some influence on its visibility, it is not the sole determining factor. Mesh size, pattern, lighting conditions, and background play a more significant role in determining the visibility of steel wire mesh.

- Q:Can steel wire mesh be used for speaker cabinets?

- Indeed, speaker cabinets can employ steel wire mesh. This multifunctional material presents numerous advantages in the context of speaker cabinets. By acting as a protective shield, it effectively thwarts the intrusion of external objects, thereby safeguarding the speaker components against potential harm. Moreover, it facilitates the smooth transmission of sound, guaranteeing an optimal audio experience. Its durability and longevity further make it an ideal selection for speaker cabinets, which encounter frequent usage and potential impacts. Ultimately, the integration of steel wire mesh in speaker cabinets serves to enhance both their functionality and visual appeal.

- Q:How is steel wire mesh used in reinforcement of dams?

- Steel wire mesh is commonly used in the reinforcement of dams to enhance their structural integrity and stability. The mesh is typically made from high-strength steel wires that are woven together to form a grid-like pattern. One of the primary uses of steel wire mesh in dam reinforcement is to provide additional tensile strength to the concrete structures. Dams are subjected to immense pressure from the water they hold back, which can cause the concrete to crack or fail over time. By placing steel wire mesh within the concrete, it acts as a reinforcement and helps distribute the tensile stress more evenly. This helps prevent the formation of cracks and increases the overall strength and durability of the dam. Moreover, steel wire mesh is also used to control thermal and shrinkage cracks in dams. Concrete tends to expand and contract due to temperature fluctuations and moisture changes. These movements can lead to the formation of cracks, which can weaken the structure. By incorporating steel wire mesh, it acts as a barrier and helps to minimize the occurrence and propagation of such cracks. Another crucial role of steel wire mesh in dam reinforcement is in providing resistance against seismic activity. Dams located in earthquake-prone regions are susceptible to ground vibrations, which can lead to severe damage. Steel wire mesh helps to absorb and disperse the energy generated during an earthquake, reducing the impact on the dam structure. This ensures that the dam remains intact and operational even in the event of seismic activity. Furthermore, steel wire mesh is also used for erosion control in dams. Water flow can cause erosion and scouring of the dam surface, which can compromise its stability. By placing steel wire mesh on the upstream face of the dam, it acts as a protective layer, preventing erosion and maintaining the integrity of the structure. Overall, steel wire mesh is an essential component in the reinforcement of dams. Its use provides additional tensile strength, controls cracking, enhances resistance against seismic activity, and helps prevent erosion. By incorporating steel wire mesh, dams can be constructed to withstand the various forces and environmental conditions, ensuring their long-term stability and safety.

- Q:Can steel wire mesh be used for architectural partitions?

- Architectural partitions can indeed utilize steel wire mesh. This material is highly adaptable and can be employed in various architectural scenarios, including partitions. Its numerous advantages, such as durability, strength, and aesthetic appeal, make steel wire mesh partitions visually pleasing and contemporary. Moreover, they offer design flexibility, enabling the creation of distinct areas within a building, dividing open spaces, or providing privacy without blocking the view entirely. Furthermore, these partitions also serve safety purposes by acting as a protective barrier while allowing light and airflow to pass through. In conclusion, due to its versatility, strength, and aesthetic qualities, steel wire mesh proves to be a suitable choice for architectural partitions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Hexagonal Wire Netting Before Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords