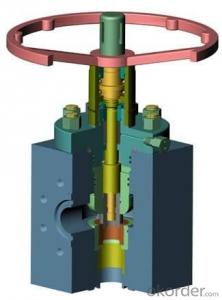

New API 6A Manual Non-rising Stem Flat Gate Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 unit

- Supply Capability:

- 1900 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | High Pressure |

| Power: | Manual | Material: | alloy | Temperature of Media: | Medium Temperature |

| Media: | Oil | Port Size: | 2-1/16 through7 1/16 | Place of Origin: | China (Mainland) |

| Model Number: | OKORDER | Brand Name: | OKORDER | WARRENTY: | ONE YEAR |

Packaging & Delivery

| Packaging Detail: | standard package |

| Delivery Detail: | 15 days |

Specifications

New API 6A Manual Non-rising Stem Flat Gate Valve

1.API 6A ISO9001 Certification

2. professional designers

3.Top quality

1) Wellhead and Christmas tree (casing/tubing head, casing /tubing hangers, crosses ,flange adaptor. fracturing equipment , tree cap etc)

2) Valve (FC/FLS gate valve, expanding gate valve, Slab gate valve ,chock valve, check valve)

3) Bop(Annular/Ram BOP)

slab gate valve is a bi-directional, with a preferred sealing side valve for application on wellheads, production trees and manifolds with working pressure at and below 5000 psi.

1 API 6A latest edition

2 Forged bonnet

3 Low operation torque

4 O-ring body/bonnet seal

5 Lubrication fittings for easy maintenance

6 Manual or actuated operation

7 Simple design assures low cost

8 Flanged or screwed outlets

Non-rising stem type flat gate valve

- Q:Com wires attached to com and all individual valve wires are attached. The valves work manually( turn on by hand), I open the valve to allow the box to take over and the sprinklers run. Is this just residual water in the lines??

- I would test the leads inside the control box first... You will have to run the controls manually to troubleshoot the problem. Get a voltage meter to test for the 24 volts at the transformer connections inside the box... If you do not have the 24 volts then the problem will be the transformer. If you have the correct voltage from the transformer then you can test each of the station terminals to common. Test through each station to see if you have 24 volts at each station terminal, but you may have to remove the wires off to test. If you do not have power coming from each station… then the problem will be the rain bird control. The next step would be testing the wires… If you reconnect the wires… test just prior at each valve location to see if you have the 24 volts between the common and each station wire… if you can prove out that there is 24 volts at this location then you’re down to the final testing. Reconnect the valves – one side to the common and the other to each station wire… Getting the power (24v) to the valve should have cleared your problem. Good Luck… Running the valves manually will not affect the operation of the rainbird control... but with my rainbird valves.. you can shut off the valves completely and disable the electrical controls of the valve... make sure that you have not closed the valve off manually preventing the electrical side... a problem with rainbird controls. This does not have anything to do with residual water in the lines... I would test this side first before you get into the electrical side... could save you a lot of time.

- Q:HowdyWas taking apart a screw down NR valve and screw lift valve and noticed the spindles were made out of different materials. Brass and Steel.I am aware that brass is non corrosive but why use steel in the other valve? Is it due to their operation, do they come or not come in contact with fluids? Is one cheaper than the other?The screw lift globe valve had a steel spindle and the screw down nr glove valve had a brass spindle.Also, if anyone knows what materials are used in the valve lid and seat are made of.Any ideas?Cheers

- *In steam service , steam flashing is one of the factor which erode the spindle ( say valve stem) *The stem serves as a connector from the actuator to the inside of the valve and transmits this actuation force. Stems are either smooth for actuator controlled valves or threaded for manual valves. The smooth stems are surrounded by packing material to prevent leaking material from the valve. This packing is a wearable material and will have to be replaced during maintenance. With a smooth stem the ends are threaded to allow connection to the plug and the actuator. The stem must not only withstand a large amount of compression force during valve closure, but also have high tensile strength during valve opening. In addition, the stem must be very straight, or have low run out, in order to ensure good valve closure. This minimum run out also minimizes wear of the packing contained in the bonnet, which provides the seal against leakage. The stem may be provided with a shroud over the packing nut to prevent foreign bodies entering the packing material, which would accelerate wear. Disc material: Cast Iron or Ductile Iron Disc Aluminum-bronze Disc Stainless Steel Disc Nickel-plated Ductile Iron Lid material: engineering plastics, Cast Iron. Seat material[hard/soft]: Seats can be integral to the valve body, that is hard metal or plastic. *Hard seat: Hardened steel,Cast Iron,EN-52 forging steel Valve Seats are made from Chrome Alloy Steel which has a high wear resistance at high temperature. Nearly all metal seated valves leak, even though some leaks are extremely small. *Soft seats can be fitted to the valve body and made of materials such as PTFE or various elastomers such as NBR, EPDM, FKM. Each of these soft materials is limited by temperature (rough maximum temperatures are listed below) NBR 80 °C EPDM 120 °C FKM 170 °C PTFE 200 °C

- Q:My pressure reducing valve (or restricting valve) was looked at by three master plumbers and they all said I need a new one. My water pressure has been low for weeks. It measures about 100 psi at the outside hose bibs, but it is very low inside and suddenly reduces after you turn on the facets inside. The shower is ok. My automatic sprinkler system is not able to work now due to low pressure. A relative of mine thinks we can just add a handle (as one is missing) on the valve and adjust the pressure ourselves. The repair of the valve is around $500-600! I am told in Texas that we have to have a permit and inspection to repair this valve. Also I was told by the last plumber that came out, that I have to install a expansion tank on my new hot water heater according to code. I'm not sure if that is a city code or federal. Please respond as to information you may have on this problem. The expansion tank is required I'm told when you have a pressure reducing valve for safety, is this true?

- The cost you quoted seems a bit high to me. Mine didn't cost anywhere near that amount in East Texas. A pressure reducing valve acts like a check valve when there is no flow. That is it closes as the pressure rises when you are not using any water. In this condition, the hot water heater can raise the pressure even higher since there is no place for the expanding water to go. That is the reason for the expansion tank. Without the expansion tank the pressure relief valve on the hot water heater can relieve unnecessarily or weep a bit.

- Q:im 28yrs old with two babies.in my heart two valves are very tight and leaking too,im going for a transplanting them in august.If there is anybody who got this problem solved please share.Thanks in advance.

- Usually with an artificial valve, you'll need to be on a blood thinner for the rest of your life. If they use a natural valve, you usually won't need the blood thinner - perhaps you will for a little while, but not permanently. You can request a natural valve, but the surgeon doesn't know what size/shape of valve you need until he actually opens you up and sees what he's working with. He has an idea, based on the x-rays and MRIs you've had done, but he won't know for sure until he actually see it. So the surgeons are going to request that the Organ Procurement Department to thaw out two or three valves, depending on what they see in the tests. You can't just keep thawing out valaves, testing them, and then refreezing them if they aren't what you are looking for, so if they turn out to not be a good fit, he's going to turn to an artificial valve. So you could request a natural valve, but because of the shape of the gap that he needs to fill, you may have to have an artificial valve. Blood thinners scare people, and your friends will tell you horror stories about how their uncle's cousin's Nephew cut his arm and bled to death because he was on a blood thinner! That could happen, but it is very rare. What does happen is that you will have to go to your doctor once a month and have a blood test, and if your blood is too thin, you need to ease off on the blood thinning medication. Or if it is too thick, you need to take more. If you're blood is too thin, you'll bruise more easily - which might be embarrassing if the bruise can be seen. Blood thinners aren't as dangerous as they make them out to be, but they can be inconvenient!

- Q:I was diagnosed with Mitral Valve Prolapse. Does anyone else have this? Does this cause panic attacks? I have heard that. What other problems does it cause?

- What is mitral valve prolapse? How does a patient with MVP feel? How is mitral valve prolapse diagnosed and evaluated? What is the treatment for MVP? Mitral Valve Prolapse At A Glance What is mitral valve prolapse? Mitral valve prolapse (also known as click murmur syndrome and Barlow's syndrome) is the most common heart valve abnormality, affecting five to ten percent of the world population. A normal mitral valve consists of two thin leaflets, located between the left atrium and the left ventricle of the heart. Mitral valve leaflets, shaped like parachutes, are attached to the inner wall of the left ventricle by a series of strings called chordae. When the ventricles contract, the mitral valve leaflets close snugly, preventing backflow of blood from the left ventricle into the left atrium. When the ventricles relax, the valves open to allow oxygenated blood from the lungs to fill the left ventricle. In patients with mitral valve prolapse, the mitral apparatus (valve leaflets and chordae) becomes affected by a process called myxomatous degeneration. In myxomatous degeneration, the structural protein, collagen, forms abnormally and causes thickening, enlargement and redundancy of the leaflets and chordae. When the ventricles contract, the redundant leaflets prolapse (flop backwards) into the left atrium, sometimes allowing leakage of blood through the valve opening (mitral regurgitation). When severe, mitral regurgitation can lead to heart failure and abnormal heart rhythms. Most patients are totally unaware of the prolapsing of the mitral valve. Others may experience a number of symptoms discussed below. The mitral valve prolapse (MVP) syndrome has a strong hereditary tendency, although the exact cause is unknown. Affected family members are often tall, thin, with long arms and fingers, and straight backs. It is seen most commonly in women from 20 to 40 years old, but also occurs in men.

- Q:if i put a power valve on my honda xlr 125 would it make my bike have faster acceleration

- A power valve is a device that manufacturers fit to the cylinders of highly-tuned 2-stroke motors. It's purpose is to vary the timing of the exhaust by changing the height of the exhaust port(s). This is done in order to allow these motors to retain some bottom and midrange power. A Honda xlr is a 4-stroke so you cannot fit a power valve to it. The exhaust port in a 4-stroke is in the cyliner head, not the cylinder wall, and it's timing is controlled by a cam acting on a poppet valve.

- Q:so here are the details. i've been using my trumpet for about 6-8 years now and 1 if not 2 valves get stuck on my trumpet. the problem is not the oil as i have over oiled them too and no go. its that when i try to put my valves back in their place and twist them they don't stay in place,move ,and making either my valves stuck or making my trumpet not do a sound. what should i do? repair shop or buy a new one? i hear the clicking sound when i put them back but still all that does is either make my valve more sticky

- Trumpet valves have metal or plastic tabs that fit into grooves on the casing. They keep the valve in allignment. It sounds like the tabs on your horn could be broken. I suggest letting a repair shop do the work.

- Q:do I need a new water heater or can this ne be fixed?

- It can be fised, you just need a new seal. Measure the width of your pipe and go get a little package of them. They probably cost $2.99. Turn your water off at the street, then drain your water heater to keep it from flooding and possible problems. unscrew the joint replace the washer and put it back together. There is a book you can get at book stores that's called Hoe To Fix Damn Near Everything. It is a must have and has saved me thousands of dollars over the years. Good Luck, Jackie b

- Q:From searching around I feel that I need to replace this on my vehicle. Is the Suction Control Valve different from the Idle Control Valve? Sometimes at a stop light the engine will stall. A couple times it has happened while driving when coasting to a turn or stop.

- I would think the suction control valve is what is also called a purge valve and is part of the emissions control circuit. It is not the same as an idle control valve nor will it cause poor running when it fails. The idle control valve will however..

- Q:I have a Burnt Valve in my Ford 302 EFI Crown Victoria. I know that i will have to have machine work done to the head but im not even gonna mess around im going to just pull both my heads off since theres alot to remove to even get to the heads i Just need a list of parts that i'm gonna have to buy for this project

- You will need a head rebuild kit: valves, valve seats, valve guides and all the seals and gaskets. You will need a valley pan gasket. Leave it to the machine shop to get all the parts that go in the head. I left out valve springs and spacers that may be worn out of spec. If you ever pulled and replaced heads, you have a good idea what you're in for. If this is your first time, get help from someone with experience so you don't end up with a basket case needing to be towed to a shop for assembly. That's a nice engine and you shouldn't try to play cheap fixing it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New API 6A Manual Non-rising Stem Flat Gate Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 unit

- Supply Capability:

- 1900 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords