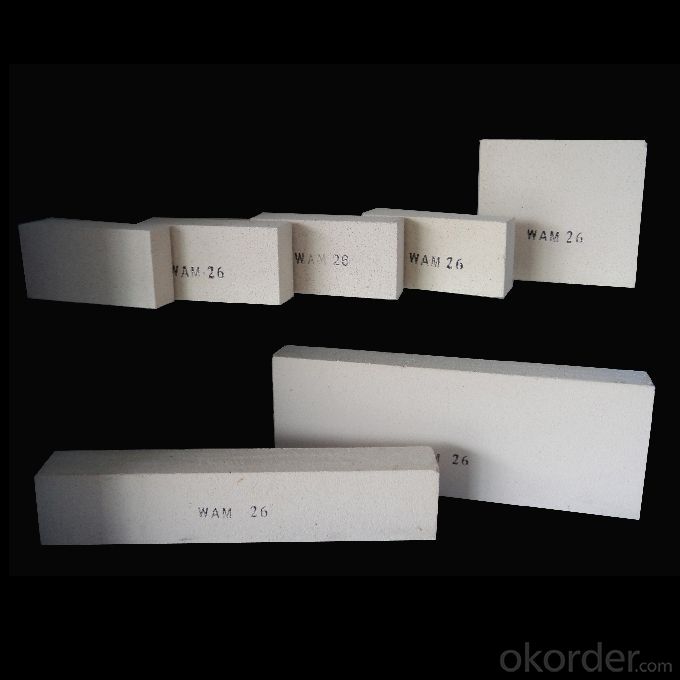

Refractory Mullite Insulating Refractory Brick JM 24

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products have all kinds of materials in the field of metallurgy, industrial furnaces, aluminum, the best Li Ning petrochemical and insulation, electric power and glass ceramics. They can be used as part of an insulation or not to melt. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen furnace, the main furnace, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: many air holes will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage, absorb more heat, energy-saving effect is obvious.

Chundu: High-speed Rail, low content of alkali metal impurities.

Accuracy: the size of the brick machining precision, cutting and grinding the special shape, speed up the brick.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

Insulating brick

- Q:Can insulating fire bricks be used for insulation in steam pipes?

- Yes, insulating fire bricks are a suitable option for insulation in steam pipes. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity, which means they prevent the transfer of heat effectively. This property makes them ideal for insulating steam pipes, as it helps to minimize heat loss and maintain the temperature of the steam inside the pipes. Additionally, insulating fire bricks are lightweight and easy to install, making them a convenient choice for insulating steam pipes.

- Q:Can insulating fire bricks be used in chimneys or flues?

- Insulating fire bricks are not recommended for use directly in chimneys or flues. While these bricks are designed to withstand high temperatures, they are primarily used for insulation purposes rather than as a structural component. Chimneys and flues require bricks that are specifically engineered to withstand the intense heat and corrosive byproducts of combustion. These bricks, known as refractory bricks, are designed to have high thermal resistance and exceptional durability to ensure the safe and efficient operation of the chimney or flue. Therefore, it is advisable to use refractory bricks instead of insulating fire bricks when constructing or repairing chimneys and flues.

- Q:What is the recommended thickness of insulating fire bricks for optimal insulation?

- The recommended thickness of insulating fire bricks for optimal insulation varies depending on the specific application and desired level of insulation. However, a typical range for insulating fire bricks is between 2.5 to 4 inches in thickness. It is important to consult with a professional or refer to specific guidelines to determine the ideal thickness for your specific insulation needs.

- Q:Are insulating fire bricks resistant to spalling?

- Yes, insulating fire bricks are resistant to spalling. Insulating fire bricks are specifically designed to withstand high temperatures and thermal shock, making them highly resistant to spalling. Spalling refers to the cracking and breaking of bricks due to exposure to extreme heat. Insulating fire bricks are made from high-quality refractory materials that have a low thermal conductivity, which helps to reduce the transfer of heat and minimize the risk of spalling. Additionally, insulating fire bricks have a high melting point, which makes them ideal for applications that involve high temperatures. Therefore, insulating fire bricks are commonly used in furnaces, kilns, and other high-temperature environments where spalling is a concern.

- Q:Why does the water drop first and then rise when the boiler fires?

- This is the reason for the zero water level gauge line below the center line of the drum. Under normal conditions for water and evaporation is balanced, after the fire, reduce the amount of steam water mixture into the drum in the evaporation decreased rapidly, reduce the volume of water bubbles, sudden contraction, drum water level decreased rapidly. But not to water change or increase (automatic), water balance is broken, the water level will rise rapidly.

- Q:Can insulating fire bricks be used in the construction of ovens or kilns for pottery?

- Yes, insulating fire bricks can be used in the construction of ovens or kilns for pottery. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for creating a stable and efficient heat environment required for pottery firing.

- Q:Can insulating fire bricks be used in refractory lining applications?

- Yes, insulating fire bricks can be used in refractory lining applications. These bricks are designed to have low thermal conductivity, making them ideal for insulation purposes in high-temperature environments.

- Q:Are insulating fire bricks chemically resistant?

- Insulating fire bricks are generally chemically resistant to a wide range of substances. These bricks are typically made from high-quality refractory materials such as alumina, silica, or a combination of both. These materials have excellent resistance to chemical attack, making insulating fire bricks highly resistant to the corrosive effects of various chemicals. However, it is important to note that the chemical resistance of insulating fire bricks can vary depending on the specific composition and manufacturing process. While they are generally resistant to most chemicals, there may be certain aggressive chemicals or extreme conditions that could potentially degrade or erode the bricks over time. To ensure the optimal chemical resistance of insulating fire bricks, it is recommended to consult the manufacturer's specifications or seek expert advice for specific applications. This will help ensure that the bricks are suitable for the intended chemical environment and will perform reliably over the desired lifespan.

- Q:Are insulating fire bricks suitable for insulation in refinery heaters?

- Insulating fire bricks are indeed suitable for insulation in refinery heaters. These heaters operate at extremely high temperatures, and the insulating fire bricks are specifically designed to withstand these temperatures and provide efficient insulation. With their low thermal conductivity, these bricks effectively prevent heat from escaping the heater, thereby reducing energy loss and improving the overall efficiency of the heater. Moreover, these bricks possess exceptional thermal shock resistance, enabling them to endure sudden temperature changes without cracking or breaking. Given the frequent temperature fluctuations experienced by refinery heaters, this quality is essential. Furthermore, the lightweight nature and easy installation process of insulating fire bricks make them a convenient choice for insulation in refinery heaters. Ultimately, insulating fire bricks prove to be an appropriate and efficient option for insulation in refinery heaters.

- Q:Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them excellent for applications where heat insulation is required. In lime production, high temperatures are required for the calcination process. Using insulating fire bricks in the construction of lime production linings helps to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them suitable for lining various parts of lime kilns and other equipment used in the lime production process. Overall, using insulating fire bricks in lime production linings can help to optimize the production process and improve the overall performance of lime production facilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Mullite Insulating Refractory Brick JM 24

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords