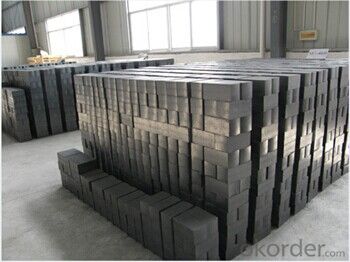

Insulating Fire Brick - Carborundum Refractory Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Passed ISO 9001;

2.57% Alumina content,or as customized;

3. Carborundum Fire Brick is widely used in iron-making.

AL2O3SiCC carborundum fire brick are universal materials for the lining of molten pretreatment equipments of molten iron tank, torpedo car, etc. The products are shaped by machine power by using dense bauxite clinkerand brown fused alumina as base materials and adding high quality SiC fines and high purity glake fraphite. It has the advantages of excellent slag resistance, thermal shock resistance, good resistance to mechanical erosion, abrasion resistance, etc.

Carborundum products belong to high grade refractory material,maximal use temperature is 1500°C,it has excellent thermal conductivity,heat shock stability,high load softening point and very good wear-resisting property,widely used in various industries with special requirement.

Item | Si3N4 bonded SiC brick | Sialon bonded SiC brick | Sialon bonded corundum brick | |

SiC, % ≥ | 72 | 70 | 80 (Al2O3) | |

Si3N4, % ≥ | 20 | 5 (N) | 5 (N) | |

Fe2O3, % ≤ | 0.7 | 0.7 | 0.7 | |

Bulk density g/cm3, ≥ | 2.65 | 2.65 | 3.1 | |

Apparent porosity %,≤ | 16 | 16 | 16 | |

CCS MPa, ≥ | 150 | 150 | 120 | |

MOR Mpa

| Room temp. ≥ | 42 | 42 | 12 |

1400°C×0.5hrs ≥ | 45 | 42 | 20 | |

Refractoriness under load °C ≥ (0.2MPa, 0.6%) | 1700 | 1700 | 1700 | |

Thermal shock resistance, cycles (Water quenching at 1100°C)≥ | 30 | 30 | 30 | |

- Q: Can insulating fire bricks be used in the construction of smelting ovens?

- Yes, insulating fire bricks can be used in the construction of smelting ovens. Insulating fire bricks are designed to have low thermal conductivity, which means they are excellent at retaining heat. This property makes them ideal for applications where high temperatures need to be maintained, such as smelting ovens. Smelting ovens are used to melt and refine various metals and minerals. These processes involve extremely high temperatures, and it is crucial to minimize heat loss to ensure efficient and effective smelting. Insulating fire bricks can help achieve this goal by providing excellent insulation and reducing heat loss. Insulating fire bricks are made from lightweight materials, such as ceramic fibers or expanded clay, which have high insulating properties. They are capable of withstanding temperatures up to 3000°F (1650°C), making them suitable for the extreme heat generated in smelting ovens. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is essential in smelting processes, which often involve heating and cooling cycles. Furthermore, insulating fire bricks are easy to work with and can be cut or shaped to fit specific dimensions or designs. This flexibility makes them highly adaptable for constructing smelting ovens of various shapes and sizes. In summary, insulating fire bricks are an excellent choice for the construction of smelting ovens due to their low thermal conductivity, high temperature resistance, thermal shock resistance, and ease of customization. They can help maintain high temperatures, reduce heat loss, and ensure efficient smelting processes.

- Q: Can insulating fire bricks be used in the construction of glass fusing kilns?

- Indeed, glass fusing kilns can utilize insulating fire bricks. These bricks are specifically crafted to endure extreme temperatures and deliver exceptional insulation, rendering them fitting for kiln application. They aid in retaining heat and guaranteeing uniform distribution within the kiln, a critical component of the glass fusing procedure. Moreover, insulating fire bricks possess the advantages of being lightweight and long-lasting, making them an ideal choice for kiln construction. They effectively minimize heat loss, enhance energy efficiency, and uphold a steady temperature inside the kiln, all of which are pivotal factors for achieving successful glass fusing.

- Q: Can insulating fire bricks be used in fertilizer plants?

- Yes, insulating fire bricks can be used in fertilizer plants. Insulating fire bricks are known for their excellent thermal insulation properties, high heat resistance, and low thermal conductivity. These properties make them suitable for various industrial applications, including fertilizer plants. In fertilizer plants, there are often processes that involve high temperatures, such as the production of ammonia or the conversion of raw materials into fertilizers. Insulating fire bricks can be used to line the walls, floors, and roofs of the furnaces, kilns, and reactors used in these processes. The thermal insulation provided by insulating fire bricks helps to minimize heat loss, increase energy efficiency, and maintain a stable temperature inside the processing units. This is crucial for controlling the chemical reactions and ensuring the optimal performance of the plant. Additionally, insulating fire bricks have a high resistance to chemical attack, which is essential in fertilizer plants where corrosive substances are often handled. They can withstand the harsh chemicals and gases present in the production environment without deteriorating or compromising their insulating capabilities. Furthermore, insulating fire bricks are lightweight, making them easier to handle and install in different areas of the plant. This can result in cost savings during construction or maintenance activities. Overall, insulating fire bricks are a suitable choice for fertilizer plants due to their thermal insulation properties, high heat resistance, chemical resistance, and lightweight nature. They can contribute to the efficient and safe operation of the plant, while also providing long-lasting performance in the demanding conditions of the fertilizer industry.

- Q: Can insulating fire bricks withstand thermal shock?

- Insulating fire bricks are designed to have high thermal insulation properties and are typically used in applications where thermal shock is not a major concern. While insulating fire bricks can withstand moderate temperature changes, they are not specifically engineered to resist thermal shock. Thermal shock occurs when there is a rapid change in temperature, causing stress and potential damage to the material. Insulating fire bricks are more susceptible to thermal shock compared to dense fire bricks, which are specifically designed to withstand extreme temperature changes. If thermal shock is a concern in your application, it is recommended to consider other types of refractory materials that are specifically designed to withstand rapid temperature changes.

- Q: Can insulating fire bricks be used in copper smelting furnaces?

- Yes, insulating fire bricks can be used in copper smelting furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in furnaces. They are made from materials that can handle the extreme heat generated during the smelting process and can effectively retain and reflect heat back into the furnace. This helps to maintain the desired temperature and improve energy efficiency. Additionally, insulating fire bricks can help to reduce heat loss, resulting in faster and more efficient copper smelting. Therefore, using insulating fire bricks in copper smelting furnaces is a common practice in the industry.

- Q: How do insulating fire bricks affect the overall noise insulation of a building?

- Insulating fire bricks can significantly enhance the noise insulation of a building. These bricks have excellent sound-absorbing properties due to their high density and ability to dampen sound vibrations. By reducing the transmission of airborne and impact noises, insulating fire bricks help create a quieter and more peaceful indoor environment.

- Q: Are insulating fire bricks resistant to carbon dioxide?

- Insulating fire bricks, also known as refractory bricks, are designed to withstand high temperatures and are generally resistant to various chemicals and gases. However, their resistance to carbon dioxide may vary depending on the specific type and composition of the insulating fire brick. Carbon dioxide (CO2) is a non-flammable gas that is usually present in the atmosphere and is released during the combustion of carbon-based fuels. In most cases, insulating fire bricks have a high resistance to carbon dioxide due to their high melting point and the presence of refractory materials such as alumina and silica. However, prolonged exposure to high concentrations of carbon dioxide, especially at elevated temperatures, can cause some insulating fire bricks to undergo chemical reactions that may lead to degradation or reduced performance. It is important to consider the specific application and environment in which the insulating fire bricks will be used. If the insulating fire bricks are part of a furnace or kiln that generates significant amounts of carbon dioxide, it is advisable to choose bricks specifically designed for such conditions. These bricks may have additional protective coatings or higher chemical resistance to ensure their longevity and performance. In summary, while insulating fire bricks generally have good resistance to carbon dioxide, it is important to consider the specific type of brick and the conditions under which it will be used to ensure optimal performance and longevity.

- Q: Are insulating fire bricks suitable for applications with high mechanical stress?

- Insulating fire bricks are not typically suitable for applications with high mechanical stress. Insulating fire bricks are designed to provide excellent thermal insulation and are made from lightweight materials such as clay, ceramic fibers, or vermiculite. While they excel at providing insulation, they are not as strong or durable as structural fire bricks or other refractory materials. Applications with high mechanical stress, such as heavy-duty furnaces, kilns, or industrial processes that involve significant movement or loading, require fire bricks that can withstand the mechanical forces involved. These types of applications typically use dense fire bricks or refractory materials that have higher compressive strength and resistance to mechanical stress. Using insulating fire bricks in applications with high mechanical stress can lead to cracking, crumbling, or premature failure of the bricks, compromising the integrity and efficiency of the system. Therefore, it is important to carefully select the appropriate type of fire bricks or refractory materials that can withstand the specific mechanical stress requirements of the application.

- Q: If there is a main component of cenosphere light insulating brick.

- Before 2003 because the price is cheaper to do so cenosphere light heat insulation brick is generally used zeeospheres. After 2003 basically replaced by fly ash and other lightweight refractory material, but some high-grade light brick or floating beads.

- Q: Can insulating fire bricks be used in cement kilns?

- Yes, insulating fire bricks can be used in cement kilns. Insulating fire bricks are designed to have low thermal conductivity, which makes them ideal for insulating high-temperature environments such as cement kilns. These bricks can help to reduce heat loss and improve energy efficiency in the kiln. Additionally, their lightweight nature makes them easier to handle and install in the kiln. However, it is important to ensure that the insulating fire bricks selected are compatible with the specific operating conditions and requirements of the cement kiln to ensure optimal performance and longevity.

Send your message to us

Insulating Fire Brick - Carborundum Refractory Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords