Non Woven Polypropylene Geotextile 3% UV Resistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

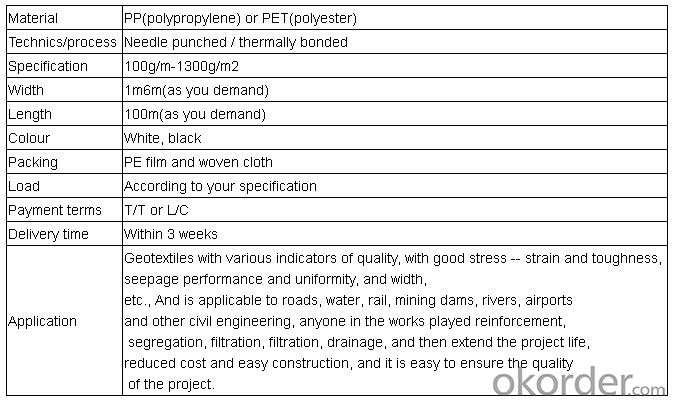

PP Geotextile Product Description:

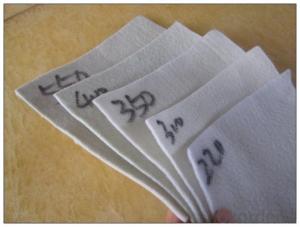

PP Geotextile Specifications:

1, Biggest Width: 6meter

2, Weight: about 1000gsm

3, Treatment: UV protect

PP Geotextile Application:

A: Subsurface drainage

B: Roadway separation

C: Hard armor underlayment

D:Asphalt overlay applications

Specification :

PP Geotextile Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

9)Fashionable design,high quality,competitive price

10)Long service life

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:How do geotextiles improve the performance of geosynthetic clay liners?

- Geotextiles improve the performance of geosynthetic clay liners by providing additional reinforcement and filtration capabilities. They act as a separation layer between the clay liner and other materials, preventing the mixing of different soil layers and enhancing the liner's stability. Geotextiles also enhance the liner's filtration properties, allowing water to pass through while preventing the migration of fine particles. This improves the overall performance and longevity of geosynthetic clay liners in various engineering and environmental applications.

- Q:What are the advantages of using geotextiles in green roof design?

- Geotextiles offer several advantages in green roof design. Firstly, they provide an effective separation layer between the growing media and the roof membrane, preventing soil erosion and protecting the waterproofing layer. Secondly, geotextiles enhance drainage by allowing excess water to pass through the growing media and into the drainage layer, preventing waterlogging and maintaining a healthy environment for plant growth. Additionally, geotextiles can act as a filtration layer, preventing fine particles from clogging the drainage system and maintaining its functionality. Overall, the use of geotextiles in green roof design improves the longevity and performance of the roof system, while also aiding in stormwater management and plant health.

- Q:How do geotextiles help with waste containment systems?

- Geotextiles help with waste containment systems by providing a protective barrier that prevents the escape of waste materials. They effectively control the filtration of liquids and gases, reducing the risk of contamination and environmental damage. Additionally, geotextiles help to reinforce the stability and integrity of waste containment structures, ensuring long-term durability and reducing the potential for leaks or failures.

- Q:Fish pond geotextile use method

- Not geotextile to use impermeable geotextile is a filtering effect

- Q:Can geotextiles be used in reservoir lining projects?

- Yes, geotextiles can be used in reservoir lining projects. Geotextiles are commonly employed to improve the stability and performance of reservoir linings by providing reinforcement, filtration, and separation functions. They can effectively prevent soil erosion, control seepage, and enhance the overall integrity and longevity of the reservoir lining system.

- Q:What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as the material type, weight, permeability, tensile strength, and filtration properties. The geotextile material should be appropriate for the specific drainage application and capable of withstanding the anticipated loads and environmental conditions. It should also have a specific weight or thickness to ensure proper performance. The permeability of the geotextile is important to allow water to flow through while preventing soil particles from clogging the drainage system. Tensile strength is a crucial factor as it determines the geotextile's ability to withstand installation stresses and potential loads. Lastly, filtration properties are essential to retain soil particles while allowing water to pass through.

- Q:Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are permeable fabrics that are used to improve the stability, drainage, and filtration of soil in various applications, including landfill construction. They are often employed to prevent soil erosion and provide support to the landfill structure, enhancing its overall stability and longevity.

- Q:Are geotextiles commonly used in canal bank protection?

- Yes, geotextiles are commonly used in canal bank protection. They provide reinforcement and stabilization to the soil, preventing erosion and maintaining the structural integrity of the canal banks.

- Q:Can geotextiles be used in waste storage facility applications?

- Yes, geotextiles can be used in waste storage facility applications. Geotextiles are commonly used in these facilities to provide erosion control, filtration, and separation of different waste materials. They help to enhance the stability and performance of the storage facility by preventing soil erosion and promoting proper drainage. Additionally, geotextiles can also be used to cover and contain waste materials, preventing any potential contamination or leaching into the surrounding environment.

- Q:Thank you, great gods

- Polyester short wire, polyester filament, polypropylene geotextile, filament woven geotextile, and so on. I professional production geotextile geomembrane and other geotechnical materials, a professional construction of the welding team, wish smooth

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

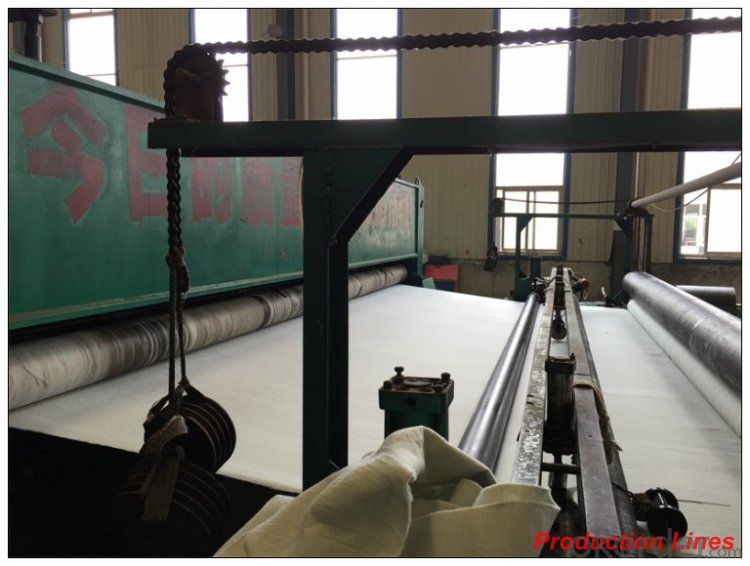

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non Woven Polypropylene Geotextile 3% UV Resistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords