Different Color Coated and Orange Pattern Embossed Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Different Color Coated and Orange Pattern Embossed Aluminum Coils

We are very proffessional in producing color coated and orange pattern embossed aluminum coils.

Normally we coat PE, PVDF, or other paint according to customers’ requirements on surface of base coils (3105, H44, etc.). Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

Stucco embossed and coated aluminum sheets have more advantages than normal aluminium coils. They look more beautiful and better at strength and rigidity than normal aluminum coils.

2. Main Features of Different Color Coated and Orange Pattern Embossed Aluminum Coils

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

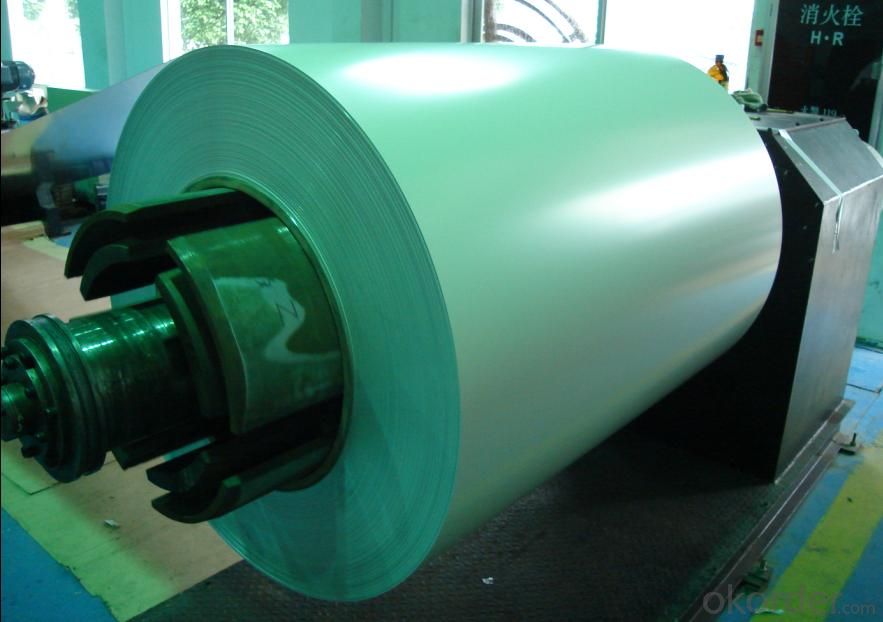

3. Different Color Coated and Orange Pattern Embossed Aluminum Coils Images

4. Specification of Different Color Coated and Orange Pattern Embossed Aluminum Coils

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Are 101 aluminum sheets suitable for automotive applications?

- Yes, 101 aluminum sheets are suitable for automotive applications. 101 aluminum is a high-strength alloy that offers good formability, corrosion resistance, and excellent weldability. These properties make it a popular choice for various automotive components such as body panels, heat shields, and structural parts. Additionally, 101 aluminum sheets are lightweight, which helps improve fuel efficiency and overall vehicle performance. Overall, 101 aluminum sheets are well-suited for automotive applications due to their strength, formability, corrosion resistance, weldability, and lightweight characteristics.

- Q:What are the advantages of using aluminum sheets in the packaging industry?

- There are several advantages of using aluminum sheets in the packaging industry. Firstly, aluminum is a lightweight material, making it ideal for packaging applications. It is significantly lighter than other packaging materials such as steel or glass, which makes it easier to handle and transport. The lightweight nature of aluminum sheets also helps reduce shipping costs, as less fuel is required to transport the packaging materials. Secondly, aluminum sheets offer excellent barrier properties. They provide an effective barrier against oxygen, moisture, and light, which are common elements that can deteriorate the quality and freshness of packaged products. This barrier helps extend the shelf life of the packaged goods, ensuring that they reach consumers in optimal condition. Additionally, aluminum sheets are highly durable and resistant to corrosion. This durability ensures that the packaged products remain protected, even in challenging environmental conditions. Aluminum sheets are also resistant to temperature variations, ensuring that the packaging material remains intact and does not warp or deform. Moreover, aluminum is a highly recyclable material. Using aluminum sheets in the packaging industry promotes sustainability and reduces the carbon footprint. Aluminum packaging can be easily recycled and reused, reducing the need for virgin materials and minimizing waste. Furthermore, aluminum sheets offer versatility in terms of design and customization. They can be easily formed and shaped into various packaging formats, such as cans, trays, foils, and pouches. This flexibility allows packaging manufacturers to create innovative and attractive packaging solutions that cater to the specific needs and preferences of different industries and consumers. Overall, the advantages of using aluminum sheets in the packaging industry include its lightweight nature, excellent barrier properties, durability, recyclability, and versatility. These benefits make aluminum sheets a preferred choice for packaging manufacturers, ensuring the protection, preservation, and appeal of packaged products.

- Q:Maybe you didn't know but in the year 2025 the earth's population will be up to 12 billion people, which is double what we have now. And i am doing a project on Aluminum, and I have to know if there is enough AL for this many people in the year 2025. So will there be enough AL in the world to support us all?

- Aluminium is the third most abundant element on earth after oxygen and silicon. I am quite sure that we will not run out of aluminium in the future. Oxygen - or at least pure good quality oxygen - is probably a more worrying scenario.

- Q:What are the standards and certifications available for aluminum sheets?

- There are several standards and certifications available for aluminum sheets, ensuring their quality and compliance with industry requirements. Some of the commonly recognized ones include: 1. ASTM International Standards: The American Society for Testing and Materials (ASTM) has developed a range of standards specifically for aluminum and aluminum alloys. These standards cover various aspects such as chemical composition, mechanical properties, and dimensional tolerances, ensuring consistent quality across different aluminum sheet products. 2. ISO 9001: The ISO 9001 certification is a globally recognized standard for quality management systems. Aluminum sheet manufacturers that are ISO 9001 certified have demonstrated their commitment to meeting customer requirements, continuous improvement, and adherence to strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has established specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for various materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for specific defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has developed a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover various aspects such as chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency across the European market. 6. RoHS Compliance: Restriction of Hazardous Substances (RoHS) compliance is crucial for aluminum sheets used in electrical and electronic equipment. This certification ensures that the aluminum sheets do not contain hazardous substances such as lead, mercury, cadmium, and certain flame retardants, thus guaranteeing their environmental safety. It is important for manufacturers and suppliers of aluminum sheets to comply with these standards and certifications to ensure the highest quality, safety, and suitability of their products for specific applications.

- Q:Hello, I dont really know anything about using a drill or cutting through metal or wood. the thing is I have a project in which I have to drill some holes in 0.04in aluminum. but I really dont know if can use regular drill bits used for drilling wood to drill the holes in my aluminum chassis. do I need to buy other drill bits for cutting metal or can I use the same ones Ive seen used for cutting wood? can I even use the same kind of drills, or do I NEED a huge bench drill with stepper bits?thanks

- Aluminum is softer than steel, so you could just use the ordinary bits that you use for wood, with a hand drill. For cleaner holes, you might want to put wood behind the aluminum as a backing. Also, if you squirt a drop of oil onto the drill area, that will help. If you're trying to drill a really large hole, it might be better to drill small ones, and enlarge with a round file.

- Q:How do I calculate the weight of aluminum sheet? What is the density?

- Weight by volume * density. With the quality, volume density.

- Q:Are aluminum sheets suitable for water storage applications?

- Yes, aluminum sheets are suitable for water storage applications. Aluminum is a corrosion-resistant material and does not rust, making it ideal for storing water without any negative impact on its quality. Additionally, aluminum sheets are lightweight, durable, and easily moldable, allowing for the construction of various water storage containers and tanks.

- Q:Can 101 aluminum sheets be painted or coated?

- Certainly! Aluminum sheets offer the possibility of being painted or coated. This adaptable material lends itself to receiving a range of finishes, including paint or protective coating, which can both elevate its visual appeal and safeguard it against corrosion. Whether it pertains to 101 aluminum sheets or any other aluminum variant, diverse techniques like spray painting, powder coating, or anodizing can be employed to paint or coat them. The selection of the appropriate paint or coating shall be contingent upon the desired aesthetics, performance criteria, and the precise utilization of the aluminum sheets.

- Q:I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- Paleohacks Cookbooks + Primal Sleep : 7ce24fc1fn4o2k6fh7paq8qa2m.hop.cl... 4 Offers: Fat Burning Kitchen, 101 Anti-aging Foods, Truthaboutabs Etc : 1bb8clh1autw9k86xhr9m26x21.hop.cl... Better Breads Guilt-free Desserts: Top Converting Health Offers! : da5acmc7fr4x2nb0r3gqy4vju7.hop.cl...

- Q:Aluminum standard 30*25*2500 to 1000 1 how to calculate the number of materials needed?. 2 how to calculate the cutting loss?

- The aluminum density of the alloy is about the same as this one, which can be roughly estimated.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Different Color Coated and Orange Pattern Embossed Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords