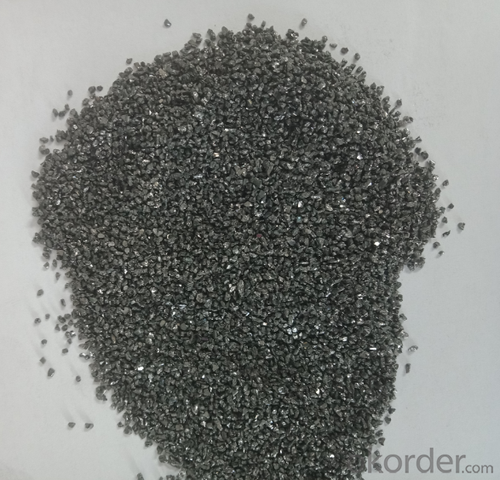

Black Silicon Carbide SIC for Metallurgy Field

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin: Ninxia, China

Application: Refractory, Steel making

Shape: Granule, Powder

Material: SiC, F.C

Chemical Composition: SiC, F.C

Product name: Silicon Carbide / Black Sic

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Usage: Metallurgy, Foundry, Abrasive, Refractory, Deoxidizer

Advantage: Timely Shipment, High quality, Good performance

Packing: 25kg/bag, 1mt/bag or as customers' requirements

Size: 0-1/1-3/3-5mm,1-10mm, 100mesh etc

Sample supply: free sample

Color: Black

MOQ: 25Mt

Supply Ability

Supply Ability:500 Metric Ton/Metric Tons per Month

Silicon Carbide

Type | Chemical Composition | |

SiC | F.C | |

≥ | ≤ | |

SiC97 | 97 | 0.3 |

SiC95 | 95 | 0.8 |

SiC90 | 90 | 2.5 |

SiC88 | 88 | 3 |

Size: 0-1/1-3/3-5mm,1-10mm, 100mesh or as customers' requirements. | ||

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

PortTianjin port

Loading:

Description:

Silicon Carbide is produced by melting a mixture of silica sand and cokes in ultra high power electric furnaces. Silicon Carbide is chemically stable and has high corrosion resistance, which makes it hard to corrode from exposure to alkali or acid. Silicon carbide is also characterized by its high hardness, outstanding heat resistance, low thermal expansion, resistance to chemical reaction, and ability to function as a semiconductor.

Application:

SiC is suitable for cupola and electric furnace, widely used in iron foundries and in steel mills as deoxidizing agent, especially in ladle furnaces and electric arc furnaces during slag treatment. Silicon carbide can improve the temperature of molten steel rapidly, shorten the melting time, play the role of deoxidizing, increasing carbon and silicon, heating to improve the quality of steel.

Feature:

Black SiC, dissolved in a basic oxygen furnace used for making steel, acts as a fuel.

1.Additional energy liberated allows the furnace to process more scrap with the same charge of hot metal.

2.Silicon Carbide can also be used to raise temperatures and adjust the carbon and silicon content.

3.Silicon carbide / SiC can reduce the cost of production, produce cleaner steel and lower emissions.

Chemical Composition

- Q: Are fire materials poisonous after burning?

- High temperature oxide materials in refractory special applications, such as aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, including metal ceramics, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: What is unshaped refractory?

- Castable. Castable refractory material factory to provide raw materials and ingredients, field processing, vibrator for compacting, maintenance must be after heat treatment, due to site conditions quality is not stable, but the integrity of the castable in concrete, two aspects of concrete as water and heat castable quality, raw materials the consumption ratio of concrete is 5% ~ 8%.

- Q: Who can introduce the difference between galvanized fireproof?coatings and steel structure fireproof materials?

- There is no difference between them because they are the coating with the same texture. But generally galvanized treatment is not necessarily needed for brushing fireproof coating. Fireproof coating and galvanized surface have relatively poor bond strength. So it is advisable to bursh trasitional lacquer or micaceous iron on galvanized surface.

- Q: Where is the sizing nozzle for refractories? Just enter the line, master into!

- This is the use of steel tapping water procedures inside!!

- Q: What's the poured refractory material?

- Frequently used poured refractory material: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nonoxide refractories like nitride, silicide, sulfide, boride and carbide, and oxide refractories like calcium oxide, chromium hemitrioxide, alumina, magnesium oxide and beryllia.

- Q: What kind of refractory materials can withstand 1500℃ when processing briquette stove core and meanwhile cost less?

- Alkali resistant castables cost the least.

- Q: can slag tailings be used to be the base materials of refractory materials ?

- the rest of it can be used as refractory additives. the scale currently used clay bricks to make high-temperature liquid. It is easy to produce large amounts of liquid because of the high iron content, instead of its refractoriness. But it can be used as refractory minaralizer.

- Q: Are refractory materials and fireproofing materials the same?

- Refractories are generally used in the industry such as power plants, electric stove and industrial furnace. They include refractory bricks and insulation materials. Fireproof materials are generally used in building and they are fireproofing.

- Q: What are fire resistant level standards of class A fire resistant door?

- Situations under which fire endurance should at least meet class A fire resistant door standard: In basement, the fire door for room where the stored combustibles average weight exceeds 30kg/㎡; in partition basement, the fire door for partition of room where the stored combustibles average weight exceeds 30kg/㎡; in high building, the fire door for equipment room of automatic fire extinguishing system, fan room and air-conditioner room; in boiler room, transformer?cabin, diesel?generator room(other dangerous rooms), the fire door in firewall. These places are special and need high security, so they need to meet the standard of class A fire resistant door. What is class A fire resistant door? New Standard for Fire Door GB12955-2008 provides that class A fire resistant door thermal insulation and refractory integrity should be no less than 1.5 hours. In other words, the key of fire door grade is the fire-resistant time. Class A fire resistant door size: class A fire resistant doors have many sizes, and can be customized according to the needs of customers. For example, the size of some fire doors of the diesel generator room is large, while the size of fire doors of basement storing combustibles is small. So the size of class A fire resistant door is also different. Usually Xinduo will take this into account, produce class A fire resistant door with various sizes and can customize according to customer requirements. Class A fire resistant door standard: as is mentioned above, for class A fire resistant door standard, the key is the fire resistant time, no less than 1.5 hours. In texture, class A fire resistant door standard is manifested in the firm joint, uniform distribution of solder joints and smooth surface coating. It has also set fireproof sealing strip which should be straight.

- Q: What are the new refractories?

- There are many of them. We can talk face to face. Sichuan Province Deyang City Xinxin Refractories Co. 0838-2228543

Send your message to us

Black Silicon Carbide SIC for Metallurgy Field

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords