Black EPDM Pond Liner Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

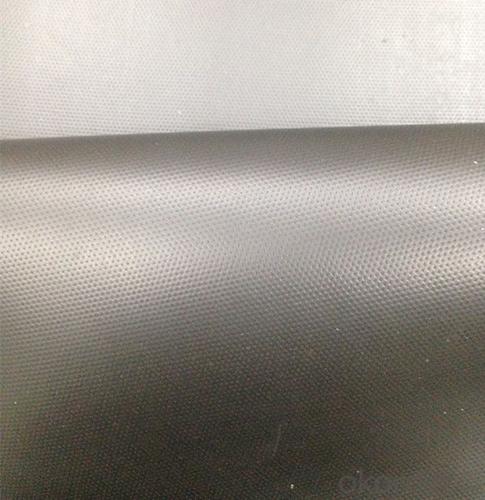

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

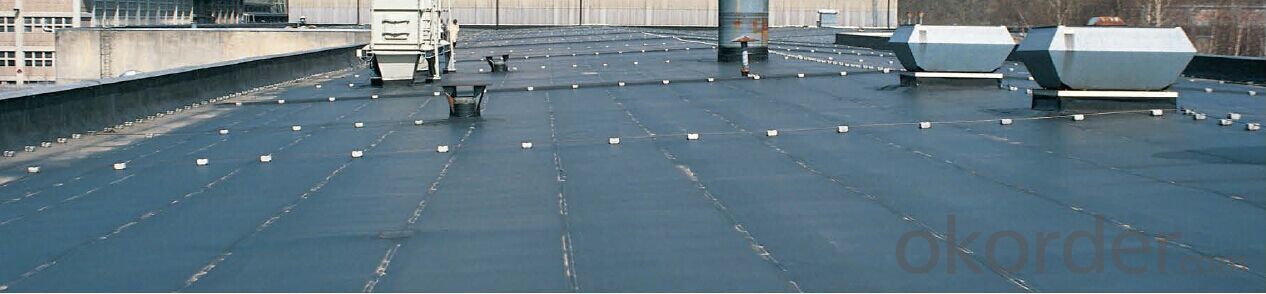

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

Photos:

- Q: Can a waterproofing membrane be used on precast concrete surfaces?

- Precast concrete surfaces, commonly used in construction for walls, floors, and roofs, are prone to water penetration. This can lead to damage and deterioration over time. To address this issue, the application of a waterproofing membrane is recommended. A waterproofing membrane is a thin layer of material, typically made of bitumen, rubber, or PVC, that is designed to prevent the passage of water. By applying this membrane to the precast concrete surface, it acts as a barrier, effectively stopping water from seeping into the concrete. There are several advantages to using a waterproofing membrane on precast concrete surfaces. Firstly, it helps to prolong the lifespan of the concrete by protecting it from water damage. Cracking, reinforcement corrosion, and the growth of mold and mildew can be minimized or avoided altogether. Secondly, the use of a waterproofing membrane improves the overall performance of the precast concrete. By preventing water penetration, the structural integrity of the concrete is maintained. Additionally, it ensures a dry and comfortable environment inside buildings by preventing water leakage. Lastly, a waterproofing membrane provides extra protection against other elements such as chemicals and UV rays. Certain membranes are resistant to chemical exposure, which is advantageous in industrial or commercial settings. Some membranes also possess UV-resistant properties, safeguarding against damage caused by prolonged exposure to sunlight. In conclusion, the application of a waterproofing membrane on precast concrete surfaces is an effective solution to prevent water penetration and safeguard the concrete from damage. It is a cost-effective and efficient method to ensure the durability and longevity of precast concrete structures.

- Q: Does a waterproofing membrane provide any insulation benefits?

- No, a waterproofing membrane does not provide any insulation benefits. Its main purpose is to prevent water from seeping through a structure, while insulation is specifically designed to regulate temperature and reduce heat transfer.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Yes, a waterproofing membrane can be used for wastewater treatment plants or sewage facilities. It helps to prevent water leakage, ensuring the containment and proper treatment of wastewater or sewage.

- Q: Are waterproofing membranes resistant to corrosion?

- Yes, waterproofing membranes are typically resistant to corrosion. They are specifically designed to withstand exposure to moisture, chemicals, and other potentially corrosive substances, ensuring long-lasting protection against water infiltration and damage.

- Q: Are there any specific installation techniques for corners and edges when using a waterproofing membrane?

- Yes, there are specific installation techniques for corners and edges when using a waterproofing membrane. These techniques are important to ensure that the corners and edges are properly sealed and protected from water infiltration. For corners, it is recommended to use corner flashings or preformed corner pieces specifically designed for waterproofing applications. These corner flashings or preformed pieces are typically made of flexible materials such as rubber or PVC and are installed over the membrane to provide a watertight seal. They should be securely fastened to the substrate and overlapped with the membrane to create a continuous barrier against water. When it comes to edges, it is crucial to install edge flashings to prevent water from seeping underneath the membrane. Edge flashings are installed along the perimeter of the waterproofing membrane and are typically made of the same material as the membrane itself. They should be properly sealed and securely fastened to the substrate to ensure a tight and reliable seal. Additionally, it is important to properly overlap the membrane at corners and edges to create a seamless and continuous barrier against water. The manufacturer's instructions should be followed carefully to ensure the correct overlap width and method. Generally, a minimum overlap of at least 2 inches is recommended for corners and edges. Overall, the specific installation techniques for corners and edges when using a waterproofing membrane involve the use of corner and edge flashings, proper sealing and fastening, and correct overlap of the membrane. Following these techniques will help to ensure a reliable and effective waterproofing system.

- Q: What is the use of waterproof membrane?

- Building waterproofing membrane is mainly used for building walls, roofs, tunnels, highways, landfills, etc., to withstand external rain, groundwater leakage can be curled into a roll of flexible building materials.

- Q: Can a waterproofing membrane be used for exterior applications?

- Yes, a waterproofing membrane can be used for exterior applications. Waterproofing membranes are often used on roofs, balconies, decks, foundations, and other exterior surfaces to provide a protective barrier against water and moisture infiltration. These membranes are specifically designed to withstand outdoor conditions and can effectively prevent water damage and leaks in exterior structures.

- Q: Can a waterproofing membrane be used for foundation walls?

- Yes, a waterproofing membrane can be used for foundation walls. Waterproofing membranes are commonly used to protect foundation walls from moisture, preventing water penetration and potential damage to the structure. These membranes are designed to create a protective barrier against water, helping to keep the foundation dry and maintaining its structural integrity.

- Q: Can a waterproofing membrane be used in geotechnical applications?

- Yes, a waterproofing membrane can be used in geotechnical applications. Waterproofing membranes are commonly used to prevent the infiltration of water into structures and are applied to various surfaces such as roofs, basements, and foundations. In geotechnical applications, these membranes can be utilized to prevent water from seeping into soil, preventing erosion, and stabilizing slopes. They can be installed horizontally or vertically to create a barrier that prevents water penetration, which can be particularly useful in retaining walls, embankments, and dams. Additionally, waterproofing membranes can also be used to control the flow of water and improve drainage in geotechnical projects. Overall, the use of a waterproofing membrane in geotechnical applications can enhance the durability and performance of structures while protecting against water-related issues.

- Q: Can a waterproofing membrane be used on precast stone surfaces?

- Yes, a waterproofing membrane can be used on precast stone surfaces. The membrane acts as a protective barrier, preventing water from penetrating the stone and causing damage. It is commonly used in construction projects to ensure the longevity and durability of precast stone surfaces.

Send your message to us

Black EPDM Pond Liner Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords