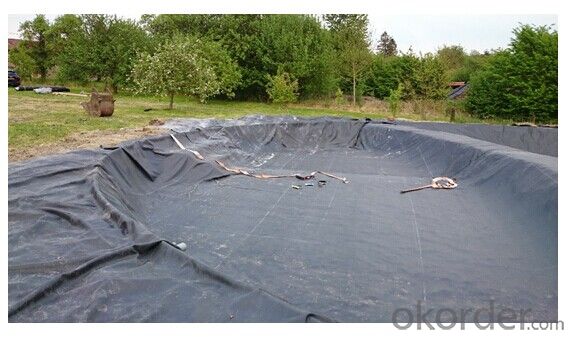

EPDM Weldable Waterproof Membrane for Pond Liner Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features for EPDM Waterproof Membrane

1)the excellent anti-aging, in the long term light, humidity, cold use of the natural environment, small changes in physical properties, used in temperature from -50 degree to 80 degree.

2)with outstanding ozone resistance, resistance to ultraviolet and atmospheric corrosion of many chemical corrosive substances.

3) high tensile strength, high elongation, high flexibility, capable of sustaining a puncture of hard material, good anti-crack, high adaptbility of the grass roots contraction and the crack and deformation, and give full play to extend the performance, playing the role of waterproofing.

4)long lifetime, high durability can achieve more than 25 years.

5)the cold construction operation, no environment pollution and simple operation.

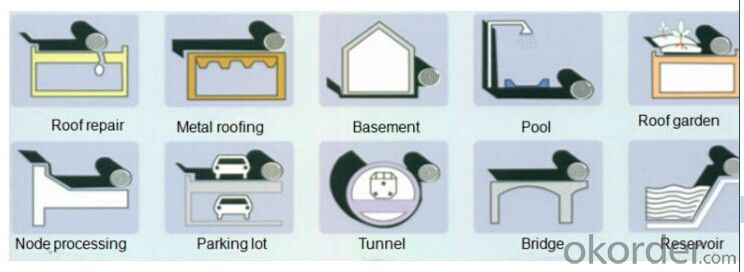

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Type | EPDM |

Material | EPDM Rubber |

Thickness | 1.2mm,1.5mm,2.0mm |

Length | 20m/roll |

Width | 1.2m |

Usage | roof/walls/bathroom/tunnel/basement/bridge/road/underground, |

Application method | Hot melt |

Length | 20m |

Surface | Smooth surface,fleece surface |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for a roof deck?

- Yes, a waterproofing membrane can be used for a roof deck. A waterproofing membrane is designed to provide a protective barrier against water penetration, making it an ideal solution for roof decks that are exposed to rain, snow, and other weather elements. The membrane is typically applied on top of the roof deck surface, creating a seamless and durable waterproof layer that prevents water from seeping into the underlying structure. This helps to extend the lifespan of the roof deck and protect it from potential water damage. Additionally, some waterproofing membranes also offer additional benefits such as UV resistance and thermal insulation, further enhancing their suitability for roof deck applications.

- Q: Can a waterproofing membrane be tiled over?

- Yes, a waterproofing membrane can be tiled over. In fact, it is highly recommended to install a waterproofing membrane before tiling in areas that are prone to moisture, such as bathrooms, showers, and outdoor patios. The waterproofing membrane acts as a barrier to prevent water penetration and protect the underlying structure from damage. Tiling directly over the membrane ensures that the tile installation remains durable and long-lasting. It is important to follow the manufacturer's guidelines and use appropriate adhesives and grouts that are compatible with the waterproofing membrane to ensure a successful and watertight tile installation.

- Q: Can a waterproofing membrane be used for seawalls or bulkheads?

- Yes, a waterproofing membrane can be used for seawalls or bulkheads. These membranes are designed to provide a barrier against water penetration and can effectively protect structures from the corrosive effects of saltwater and wave action. This makes them suitable for use in constructing and maintaining seawalls and bulkheads, ensuring their durability and longevity.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Yes, there are specific tools and equipment required for installing a waterproofing membrane. Some of the essential tools and equipment include: 1. Protective gear: This includes gloves, goggles, and a face mask to protect yourself from any harmful chemicals or fumes. 2. Cleaning equipment: Before installing the membrane, the surface needs to be clean and free from any dust, debris, or loose particles. Therefore, you may need a broom, vacuum cleaner, or pressure washer to clean the area properly. 3. Waterproofing membrane: The specific type of membrane will depend on the project requirements, but it is essential to have the appropriate membrane material and enough coverage to ensure a proper seal. 4. Primer: In some cases, a primer may be needed to enhance adhesion between the surface and the membrane. The primer type will depend on the surface material and the membrane being used. 5. Application tools: These tools are used to apply the membrane onto the surface. Common tools include brushes, rollers, or sprayers. The choice will depend on the type of membrane and the size of the project. 6. Seam tape: If the waterproofing membrane requires seams, a seam tape will be needed to ensure a watertight seal at the joints. The tape should be compatible with the membrane material. 7. Adhesive or adhesive tape: Some waterproofing membranes require an adhesive to bond them to the surface. Alternatively, adhesive tape can be used for self-adhesive membranes. 8. Cutting tools: Depending on the shape and size of the area to be waterproofed, you may need cutting tools such as utility knives or scissors to trim the membrane to the desired size and shape. 9. Caulking gun: A caulking gun is necessary for applying sealant or caulk to fill any gaps or cracks in the surface before installing the membrane. 10. Drying equipment: After the membrane is installed, it may require a certain amount of time to dry or cure. Fans or dehumidifiers may be needed to accelerate the drying process, depending on the specific membrane and environmental conditions. It is important to consult the manufacturer's guidelines or seek professional advice to ensure you have all the necessary tools and equipment for a successful installation of the waterproofing membrane.

- Q: Can a waterproofing membrane be used in combination with insulation materials?

- Indeed, the utilization of a waterproofing membrane alongside insulation materials is highly recommended. This combination offers heightened defense against water damage and moisture infiltration. The waterproofing membrane functions as a protective barrier, preventing water from infiltrating the building envelope, while the insulation materials regulate temperature and enhance energy efficiency. Merging these two components results in a sturdier and more efficient building envelope system. However, it is crucial to verify the compatibility of the selected waterproofing membrane with the insulation materials and adhere to proper installation techniques to guarantee a secure seal and optimal performance.

- Q: Can a waterproofing membrane be tested for quality or performance?

- Indeed, it is possible to assess the quality and performance of a waterproofing membrane through various tests. Effectiveness and durability can be evaluated by conducting several tests. One such test is the water penetration test, which involves subjecting the membrane to a specific level of water pressure to determine if any water can pass through it. Another evaluation is the adhesion test, which assesses the strength of the bond between the membrane and the substrate. Furthermore, tests can be carried out to gauge the membrane's resistance to chemicals, UV radiation, temperature fluctuations, and physical stress. These tests contribute to determining if the membrane meets the required standards and can effectively function under diverse conditions.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Yes, waterproofing membranes can be installed on uneven surfaces. However, to ensure effective installation, it is important to properly prepare the surface by leveling or smoothing it out as much as possible before applying the membrane.

- Q: Can a waterproofing membrane be used in foundations?

- Foundations can benefit from the use of a waterproofing membrane. Installing such a membrane is often recommended to prevent water infiltration and protect the structure from potential damage. This barrier is typically applied to the exterior walls of the foundation, effectively blocking water penetration. By keeping the foundation dry, it safeguards against cracks and leaks caused by hydrostatic pressure. Moreover, a waterproofing membrane helps prevent moisture buildup, mold growth, and other water damage-related issues. Overall, incorporating a waterproofing membrane in foundations is a dependable and effective approach to ensure the long-lasting stability and durability of a building.

- Q: Can a waterproofing membrane be used for airport runways?

- Yes, a waterproofing membrane can be used for airport runways.

- Q: Is the foundation pit waterproofing and the foundation pouring on the working face?

- 1, foundation pit membrane waterproof is the entire basement part of the package. So the basic floor of the waterproof material and the external walls of the waterproof material as much as possible.

Send your message to us

EPDM Weldable Waterproof Membrane for Pond Liner Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords