EPDM Waterproof Membrane for Pond Liner Use with Pure Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

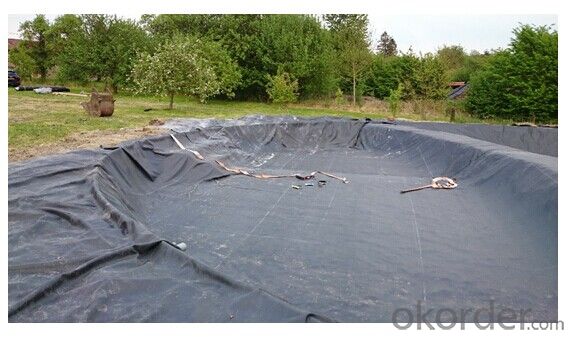

Introduction for EPDM Waterproof Membrane

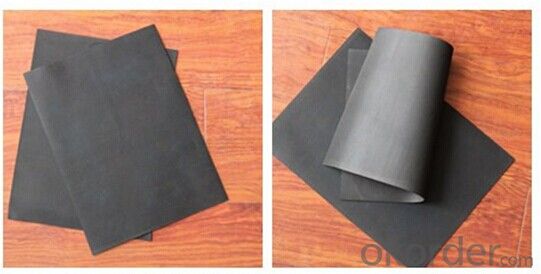

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

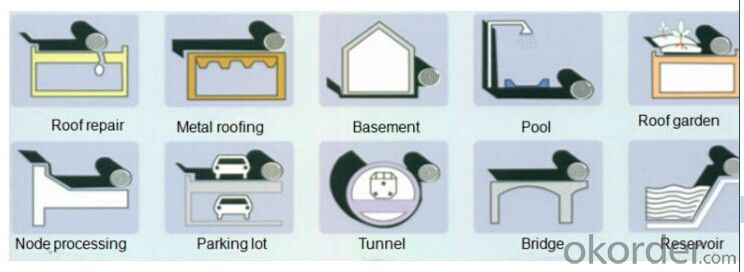

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Type | EPDM |

Material | EPDM Rubber |

Thickness | 1.2mm,1.5mm,2.0mm |

Length | 20m/roll |

Width | 1.2m |

Usage | roof/walls/bathroom/tunnel/basement/bridge/road/underground, |

Application method | Hot melt |

Length | 20m |

Surface | Smooth surface,fleece surface |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: APP selection of asphalt waterproofing membrane selection points

- 3, Ⅱ type fiberglass fetal APP modified asphalt waterproofing membrane tension is higher, dimensional stability and heat resistance, good, but no elongation. Suitable for general and relatively cold areas and stable structure of the general engineering roof or underground waterproofing works.

- Q: Can a waterproofing membrane be used for swimming pool decks?

- Yes, a waterproofing membrane can be used for swimming pool decks. Waterproofing membranes are designed to provide a barrier against water penetration, making them an effective solution for protecting pool decks from water damage and leaks.

- Q: Polyurethane and SBS membrane waterproof

- Paste asphalt linoleum. The cold binder material prepared by diluting the bitumen with solvent is developing. Various solvent and water emulsion asphalt or asphalt rubber coatings for roof waterproofing, should be strictly selected anti-cracking, tensile, anti-aging performance and good weatherability thick coating varieties. In addition, all kinds of ointment for dealing with the general building of the joints waterproof.

- Q: Can a waterproofing membrane be used for a shopping mall?

- Yes, a waterproofing membrane can be used for a shopping mall. Waterproofing membranes are commonly used in commercial buildings, including shopping malls, to prevent water infiltration and protect the building's structure from water damage. They provide an effective barrier against water and are often used in areas such as basements, roofs, and foundations to ensure the building remains dry and protected.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- A waterproofing membrane is capable of protecting against the growth of mold or mildew, as they thrive in environments that are damp and moist. The membrane acts as a barrier, preventing water from entering the building structure. This effectively keeps the area dry and greatly reduces the likelihood of mold or mildew growth. Furthermore, waterproofing membranes often contain anti-microbial properties that further hinder the growth of mold and mildew. Nevertheless, it is important to remember that while a waterproofing membrane can offer substantial protection against mold and mildew, it is not a foolproof solution. It is crucial to ensure proper ventilation and carry out regular maintenance to prevent these issues.

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Yes, a waterproofing membrane can be used on precast nickel surfaces. Waterproofing membranes are designed to create a barrier against moisture and prevent water penetration. They can be applied to various surfaces, including concrete, metal, and even nickel. However, it is important to ensure that the waterproofing membrane is suitable for use on nickel surfaces and is compatible with the specific type of precast nickel being used. It is recommended to consult with a professional waterproofing contractor or the manufacturer of the membrane for guidance on the specific application and to ensure proper adhesion and effectiveness of the membrane on precast nickel surfaces.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Certainly, a waterproofing membrane can be utilized alongside green building practices. In actuality, integrating a waterproofing membrane into the construction of a green building can greatly enhance its overall sustainability and efficiency. One of the fundamental principles of green building practices is to maximize energy efficiency and decrease the environmental impact of a structure. By installing a waterproofing membrane, the building's outer covering can be shielded from moisture intrusion, thereby preventing water damage and potential mold growth. This, in turn, aids in preserving the structural integrity of the building, reducing the necessity for costly repairs and replacements, which can consume resources and generate waste. Moreover, a waterproofing membrane can contribute to improved indoor air quality. By preventing water infiltration, it assists in creating a dry and healthy living or working environment, minimizing the risk of respiratory problems and other health issues associated with dampness. Furthermore, a waterproofing membrane can enhance the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it lessens the potential for heat loss through moisture evaporation, thus reducing the energy required for heating and cooling. This can lead to decreased energy consumption and lower carbon emissions, aligning with the objectives of green building practices. However, it is crucial to select a waterproofing membrane that is environmentally friendly and compliant with green building standards. Seek out membranes that are crafted from recycled or sustainable materials and possess low VOC (volatile organic compound) content. Additionally, consider opting for a membrane that is designed for longevity and durability, as this can further minimize the environmental impact by reducing the need for replacement over time. In conclusion, a waterproofing membrane can be an invaluable addition to any green building endeavor. It serves to safeguard the building envelope, enhance indoor air quality, and improve energy efficiency. By choosing an environmentally friendly membrane, the overall sustainability of the building can be further enhanced.

- Q: What is the cost of a waterproofing membrane?

- The cost of a waterproofing membrane can vary depending on factors such as the type and quality of the membrane, the size of the area to be covered, and the complexity of the installation. It is best to consult with manufacturers or contractors to get accurate cost estimates for specific projects.

- Q: Can a waterproofing membrane be applied in wet conditions?

- Yes, a waterproofing membrane can be applied in wet conditions. However, it is important to ensure that the surface is clean, dry, and free of any standing water or moisture before applying the membrane. Additionally, certain types of waterproofing membranes may have specific instructions or recommendations for application in wet conditions, so it is advisable to consult the manufacturer's guidelines for best results.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures or tears. It is typically made from durable materials such as PVC, TPO, or EPDM, which are known for their strength and resistance to damage. These membranes undergo rigorous testing to ensure their ability to withstand various environmental conditions and potential sources of punctures or tears, such as sharp objects or heavy foot traffic. Additionally, some waterproofing membranes come with reinforcement layers or added protection to further enhance their puncture and tear resistance. However, it is important to note that while waterproofing membranes are highly resilient, they are not completely impervious to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help maximize its longevity and performance.

Send your message to us

EPDM Waterproof Membrane for Pond Liner Use with Pure Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords