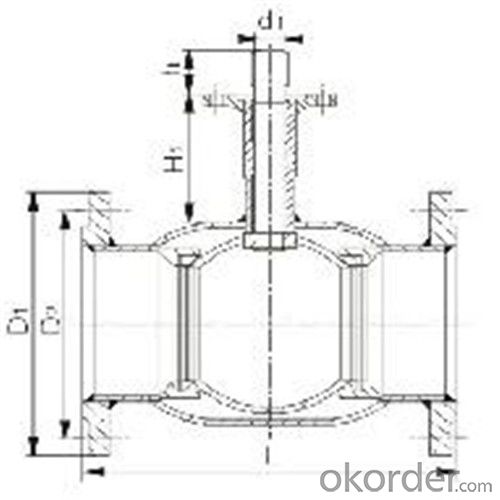

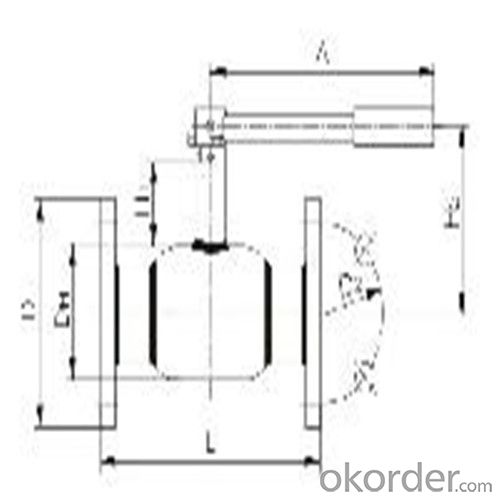

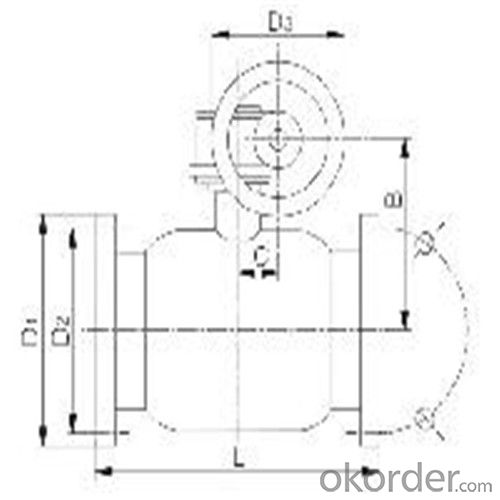

Ball Valve For Heating SupplyDN 32 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

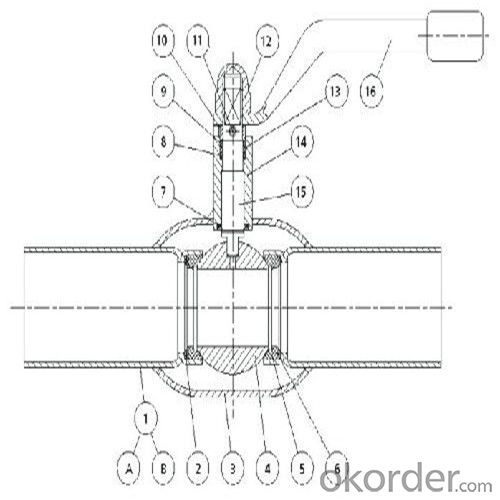

Product Description of Ball valve for heating supply:

Technical introduction

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: i was filling the tire on my car and the valve stem completely came out when i finished, quickly deflating the tire. i could push it back in but then the process repeated itself when i tried refilling it again. is there part of the stem i'm not seeing. the stem that i saw was long and straight and threaded. advise, thoughts? thanks.

- Tubeless Tire Valve

- Q: Im trying to replace the egr valve on a 97 lincoln continental. I need to find out what size wrench I need, to get the nut off. Do you know?

- I am assuming you want to replace the EGR valve because you are getting an insufficient EGR flow trouble code. Before you replace a perfectly good valve with an inferior aftermarket part that will likely fix nothing, a little more diagnosis is in order. If you have access to a scan tool and a vacuum gauge, perform a KOER (key on engine running) test on the engine with the vacuum gauge connected to the hose to the EGR valve. When self-test reaches the EGR test, look for the vacuum guage to move during the self test. If it moves, the vacuum source and EGR solenoid are good. If not, trace the vacuum harness for leaks. Without the scanner and vacuum gauge, find a length of hose and suck on the hose, or connect to other vacuum source to test the valve. You are looking for an RPM drop at idle when you open the valve in this way. I suspect your problem is a passageway clogged with carbon. Remove the valve and throttle body to access the clogged areas and manually decarbonize. This is the most common reason for an insufficient EGR flow on a Lincoln, along with a faulty DPFE sensor or related hoses. My money is on the clogged passages or the bad DPFE sensor.

- Q: Ok I recently changed my pcv valve and today when I was checking my spark plugs I noticed and valve that looked exactly like a pcv valve on the passenger side valve cover iam not sure exactly what this valve is ?? I should note that I changed the pcv valve on the driver side because I noticed that it was just a hose coming out of a rubber grommet and into the back of the carb was that just a breather hose ? Thanks in advance for any info

- to add, support, you can simply soak pcv valve in fuel. the little eliment filter as well. pcv valve is a hard part. rattles when shaken? it's good. elliment filter is not a paper one. it too can merely be soaked. i've seen a few pcv valves that are bad. those were on engines that sat in yards for years and years. oil dried and set. had ridges that did not let the ball rattle. other than that, never seen one go bad. just need cleaning.

- Q: Hi, I have Orbit valve for a section of my yard. The pressure is really low when I turn it on with my remote. When I turn it on manually at the valve, the water pressure is much higher.

- Its possible the valve stem is corroded with stuff not letting it actuate properly open. Turn water off and unscrew the valve then actuate it electrically while watching for a full stroke. Make sure flow control is all the way open when inspecting valves stroke. Remember where you had it set when done or readjust. Also check the solenoid for corrosion and clean linkages. I would clean and coat with petroleum jelly. My guess is valve seat is gummed up so lube the stem and work it manually till it slides open and closed easy then test with the solenoid. Good luck!

- Q: I was wondering if the pressure relief valve can be vented right under the house or does it have to be ran to the outside of the house. Also is there another method such as a catch pan that I can employ? I live in Washington.

- I would be curious to see what plumbing professionals have to say about this. From what I could find, the codes for water heater relief valves just say that the valve must have a drain pipe that discharges the hot water and steam down low, instead of up near the top where it can spray in your face. They also say that the discharge should be outside of the building, but that this is not always feasible and you can install a drip pan below the water heater for this purpose. In this case, I would think that running the discharge line to underneath the house should be okay. But, I'm not a plumber. For what it's worth, my water heater is in a closet that's accessed from outside and the discharge line from my pressure relief valve just discharges to the bottom of the closet (this was installed by a licensed plumber and signed off by the city on a remodel 2 years ago). Apparently, it's okay to just let the discharged water flow out from underneath the water heater closet door to the outside. So, I don't see why it would be against code to run the discharge line to a crawl space under the house. The point of the codes is to prevent your water heater from exploding and destroying your house (or killing or injuring you).

- Q: I think they need to be taught how to count. Honesty... Half-Life, Half-Life 2, Half-Life 2: Episode One, Half-Life 2: Episode Two... Where the hell is 3 already?

- HAHA! that is a good question! I don't know, maybe they just like continuation sequels rather than a whole new version of the game. At least they're making a third left 4 dead!

- Q: First off I'm a girl. :) My 2.0 non turbo engine has a bent valve. I have been asked to pick up the valve. But I need to know if its for the intake or the exhaust. I know the guy how is going to fix it said he will have to sand down the cylender that it goes in it. The car sounds like it knocking when driving or sitting still. The guy who is going to fix it is at work right now and I'm suppose to order this part right now. Is it an intake or an exhaust valve?

- tell him that you dont sand down the seat.if he does,then he could get it so it wont seat right.he needs to lap the seat.now 1 of the valves are smaller then the other.if it backfires through the exhaust then its the exhaust valve.if he know how to do it,then all he has to do is take a piece of paper and hold it up to the tailpipe and see if it sucks the paper in.

- Q: Could my subs kill my EGR valve? I replaced my O2 sensor and my check engine light didn't go off. So I had it checked again and the same problem was still there. It said that all the cylinders were running either rich or lean..... I can't remember. But I was told it could be the EGR Valve so I replaced it and for about a week the check engine light was off.Now its back on. Had it checked again and the same deal was going on. Oh there was also a low voltage reading..... which is why I'm thinking its my subs.So could it be my subs that keeps killing my EGR valve? And any solutions will be helpful. I don't want to have to replace my alternator because its in an extremely tough place to reach. And I already have a small Cap.... .5. My subs handle 600 RMS total. WOuld getting a bigger Cap help?

- Thank you for having such a powerful system! I am investing in hearing aids, and you and hundreds of thousands like you will make me rich in my retirement! The sub-woofers are not affecting your EGR valve. It is operated by a vacuum controlled by the ECM to regulate how much exhaust gas is to be fed back into the engine to control the NOx emissions. You want to make sure that there is no recall on the controller, or that it hasn't' failed. Follow the vacuum hose on the EGR valve to where it goes. That is the controller. Do a google search or look on Expert Village for a video.

- Q: does my 96 accord have an oriface valve or the other kind of valve? if so where is it? because im pretty sure that is the problem with my a/c not being cold at all

- It uses an expansion valve inside the evaporator assembly, part 11 in the first source. If the evaporator valve is not working the compressor will be damaged - by no oil if the valve stays closed or by slugs of liquid spilling out of the evaporator if it sticks open. Fortunately, orifices and expansion valves are very reliable. I bet a standard A/C service (about $100) will get you cool again. If you do anything to disturb the refrigerant loop (trying to charge it at home, trying to change refrigerant system parts) you will only spend more... probably a lot more.

- Q: Hey Guy! So I Was Thinking About Buying A 93 Honda Del Sol For $1800, But The Guy State That It Need A Valve Job Now Im Not To Sure What Is A Valve Job Is And How Much It Would Cost... So Please Help Me Out... I Really Need A Car :-/If Needed I Live In South Of California

- Nissan skylines are the two 4 cylinder or 6 and clearly this one is a 6... properly it somewhat is no longer the perfect description...if valves are worn or sticking you could lose compression. Compression is while the piston compresses the air/gasoline mixture and if the cylinder has a leak someplace then you somewhat finally finally end up dropping some potential and gasoline performance. Doesnt propose the top of the international - a mechanic will could desire to do a compression attempt to confim and there is an possibility they'll could desire to eliminate the pinnacle (genuine element of motor housing the camshaft and valvetrain) to evaluate what's inflicting the compression loss. perchance a valve spring or lifter is worn. with a bit of luck it won't value too plenty.

Send your message to us

Ball Valve For Heating SupplyDN 32 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords