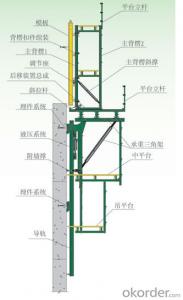

Auto-Climbing Formwork, for high buildings and bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 20 /month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

The power of the Auto climbing Formwork is the hydraulic system, which includes theoil cylinder and two commutators etc. The commutators can control the climbing of climbing rail and the bracket. The steel rail and the bracket can inner-climbing, so the whole system will climb upsteadily.

Cranes are not needed during the constructing. It is easy to operate, highly efficient and safe. It is the best choice for the construction of highbuildings and bridges.

Characteristics

Safety:

1.The system can climb integrallyor separately.

2.The climbing process is steady,synchronous and safe.

3.Excellent operating platform handrail and aisle can be lifted together with the formwork.

4.The climbing speed is quick, which can shorten the construction period and reduce the construction cost.

- Q: Can a steel prop be used to support a suspended ceiling?

- Support for a suspended ceiling can indeed be provided by a steel prop. In construction, these props, also referred to as adjustable or telescopic props, are frequently utilized for temporary support. They are commonly employed to bolster formwork, scaffolding, or other structures during construction or renovation projects. In terms of suspended ceilings, steel props can be utilized to offer support for the ceiling grid and panels. These props can be adjusted in height, which facilitates easy leveling and adjustment of the suspended ceiling system. They possess considerable strength and stability, enabling them to bear the weight of the ceiling materials, as well as any additional fixtures or equipment attached to the ceiling. Before utilizing steel props to support a suspended ceiling, it is crucial to ensure proper installation and positioning of the props to provide sufficient support. The weight and dimensions of the ceiling materials should be carefully considered to determine the appropriate number and placement of the props. Furthermore, it is essential to adhere to the manufacturer's instructions and guidelines for the use of steel props to ensure safety and structural integrity. All in all, steel props offer a reliable and effective solution for supporting a suspended ceiling, delivering stability and durability to the ceiling system.

- Q: Are steel props adjustable for uneven ground conditions?

- Yes, steel props are adjustable for uneven ground conditions. Steel props, also known as steel acrow props or steel shore props, are designed to provide temporary support to structures during construction or renovation projects. These props consist of an outer tube, an inner tube, and a threaded screw jack mechanism that allows for height adjustment. To accommodate uneven ground conditions, steel props are equipped with a base plate that can be adjusted to different angles. This allows the prop to be securely placed on uneven surfaces such as slopes or uneven terrain. By adjusting the base plate, the prop can be leveled and stabilized, ensuring proper support for the structure. Furthermore, steel props are available in various sizes and load-bearing capacities, allowing them to be used in different applications and supporting different weights. This versatility makes them suitable for a wide range of projects, including those on uneven ground conditions. It is worth noting that while steel props provide adjustable support for uneven ground conditions, it is important to assess the stability and safety of the surrounding area. In some cases, additional measures such as shoring or ground stabilization techniques may be required to ensure the safety of the structure and personnel working on the site.

- Q: Are steel props resistant to corrosion?

- Yes, steel props are generally resistant to corrosion due to their protective coating and high durability. However, their resistance to corrosion can vary depending on the specific steel composition and the environmental conditions they are exposed to.

- Q: Are steel props adjustable with mechanical screw mechanisms?

- Yes, steel props can be adjustable with mechanical screw mechanisms. Steel props are temporary support structures used in construction projects to provide support to beams, walls, and ceilings. They are often used in situations where adjustable height and load-bearing capacity are required. Mechanical screw mechanisms are commonly employed in steel props to allow for easy adjustment. These mechanisms typically consist of a threaded rod or screw that can be rotated to extend or retract the prop, thereby adjusting its height. The screw mechanism is usually operated using a handle or lever, making it simple and efficient to adjust the prop to the desired height. The use of mechanical screw mechanisms in steel props offers several advantages. Firstly, it allows for precise and accurate height adjustment, ensuring that the prop can be set to the required height with ease. This feature is particularly useful in construction projects where different floor levels or uneven surfaces need to be supported. Additionally, the mechanical screw mechanism provides stability and strength to the steel prop. The threaded rod or screw is designed to withstand heavy loads and provide reliable support. This ensures that the steel prop remains secure and can effectively bear the weight of the structure it is supporting. In conclusion, steel props can indeed be adjustable with mechanical screw mechanisms. This feature allows for easy and precise height adjustment, making steel props an essential tool in construction projects that require temporary support structures.

- Q: How do you ensure the stability of a steel prop?

- To maintain the stability of a steel prop, various factors must be taken into account and dealt with. The first and most important factor is to ensure that the prop adheres to industry standards and guidelines in terms of design and manufacturing. This involves using top-quality materials, following proper fabrication techniques, and carrying out thorough quality control checks. Aside from the design and manufacturing aspects, proper installation plays a crucial role in guaranteeing the stability of a steel prop. It is essential to place the prop on a solid and level surface to avoid any tilting or shifting. Additionally, it is vital to securely attach the prop to the structure it is supporting using appropriate fasteners or connectors. Regular inspections and maintenance are indispensable for the long-term stability of a steel prop. Periodic checks should be conducted to detect any signs of damage, wear, or deterioration. Any issues that arise should be promptly dealt with, either through repairs or replacements, to prevent further instability or potential failure. Furthermore, ensuring proper load distribution is of utmost importance for the stability of a steel prop. The load should be evenly spread across the prop, and its capacity should not be exceeded. Overloading a prop can result in excessive stress and strain, compromising its stability and potentially leading to collapse. Lastly, it is crucial to consider environmental conditions and potential external forces that may impact the stability of a steel prop. Factors such as wind, seismic activity, or nearby construction activities should be taken into account. Adequate precautions, such as bracing or additional support, may be necessary to ensure the prop remains stable under these conditions. Overall, maintaining the stability of a steel prop requires a combination of proper design, installation, maintenance, load management, and consideration of external factors. By adhering to industry standards, conducting regular inspections, and promptly addressing any issues, the stability of a steel prop can be effectively upheld.

- Q: Are steel props adjustable in both tension and torsion?

- No, steel props are typically adjustable in tension only and not in torsion. Steel props are commonly used in construction to support vertical loads and provide temporary support for structures. They are designed to be adjustable in length to accommodate different heights and can be locked in place to provide stability and prevent any movement or collapse. However, torsion refers to the twisting or rotational force on an object, and steel props are not specifically designed to withstand or adjust for torsional loads. Torsional loads are typically addressed through the design and selection of other structural elements, such as beams or columns, that are specifically engineered to resist twisting forces.

- Q: Can steel props be used for temporary support in bridge maintenance work?

- Yes, steel props can be used for temporary support in bridge maintenance work. Steel props are commonly used in construction projects to provide temporary support to structures and are particularly useful in bridge maintenance work. They are adjustable in height and can be easily installed and removed, making them an ideal choice for temporary support. Steel props provide stability and load-bearing capacity, ensuring the safety of workers and the integrity of the bridge during maintenance activities. Additionally, steel props can be used in various configurations and can be adjusted to accommodate different bridge designs and load requirements. Overall, steel props offer a reliable and efficient solution for temporary support in bridge maintenance work.

- Q: How do you ensure proper communication between different work teams using steel props?

- To ensure proper communication between different work teams using steel props, it is essential to establish clear channels of communication and regularly communicate with all team members involved. This can be achieved through various means, such as daily team meetings, email updates, project management software, or even in-person discussions. It is crucial to encourage an open and inclusive environment where team members feel comfortable sharing information and asking questions. Additionally, providing detailed instructions, guidelines, and documentation regarding the use of steel props can help ensure proper and consistent communication among teams.

- Q: Can steel props be used for supporting overhead cranes?

- Yes, steel props can be used for supporting overhead cranes. Steel props are commonly used in construction and engineering industries to provide temporary support and stabilization for various structures, including overhead cranes. Steel props are strong, durable, and able to withstand heavy loads, making them suitable for supporting the weight and load of overhead cranes. However, it is important to ensure that the steel props are properly designed, installed, and maintained according to industry standards and regulations to ensure safety and optimum performance. It is recommended to consult with a qualified engineer or crane manufacturer to determine the appropriate type and specifications of steel props required for supporting overhead cranes based on the specific requirements and load capacity of the crane system.

- Q: How do you maintain a steel prop?

- To maintain a steel prop, you can follow a few simple steps. Firstly, regularly inspect the prop for any signs of damage or wear and tear. This can include checking for cracks, dents, or rust. If any issues are identified, it is important to address them promptly to prevent further damage or potential safety hazards. Secondly, clean the prop regularly using a mild detergent or soap and water. This will help remove any dirt, debris, or corrosive substances that could harm the steel. After cleaning, ensure you thoroughly dry the prop to prevent any moisture from causing rust. Lastly, consider applying a protective coating or paint to the steel prop to provide an additional layer of defense against rust and corrosion. Regularly monitoring and maintaining the prop will help extend its lifespan and ensure its safe and effective use.

Send your message to us

Auto-Climbing Formwork, for high buildings and bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 20 /month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords