Auto-climbing Formwork systems for different constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure ofSingle Side Climbing Bracket SCB 180

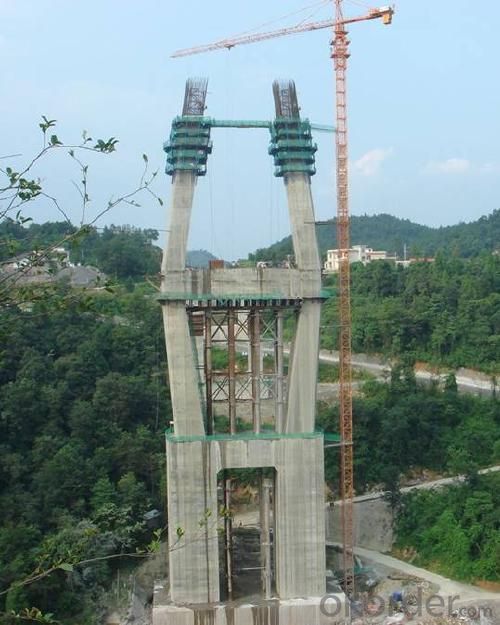

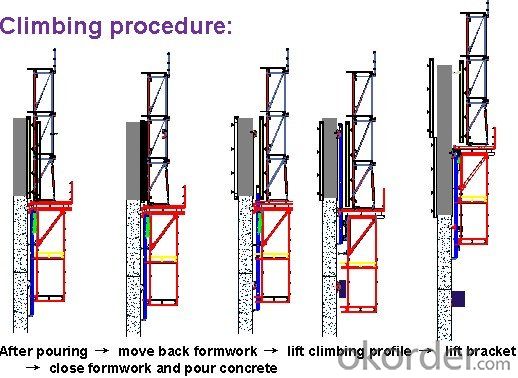

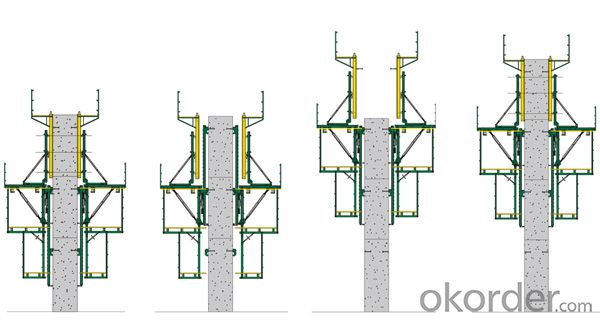

The power of the Auto-climbing Formwork is the hydraulic system, which includes the oil cylinder and two inverting boxes. The inverting boxes can control the climbing of climbing rail and the bracket. The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily. Cranes are not needed during the climbing. It's easy to operate, highly efficient and safe. It's the best choice for the construction of high buildings and large bridges.There are mainly two types of standard auto-climbing formwork, ACS-50 and ACS-100.

2. Main Features ofSingle Side Climbing Bracket SCB 180

Economical and safe anchoring

Stable and cost-effective for high loads

Simple and flexible planning

3.Single Side Climbing Bracket SCB 180images

4.Single Side Climbing Bracket SCB 180 Specifications

The M30/D20 climbing cones have been designed especially for single-sided concreting usingSCB180 in dam construction, and to allow the transfer of high tensile and shear forces into the stillfresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.generous bracket spacings allow large-area formwork units with optimal utilization of the bearingcapacity. This leads to extremely economical solutions.

5.FAQ of Single Side Climbing Bracket SCB 180

1) What can we do for you?

.We can ensure the quality of Single Side Climbing Bracket SCB 180paneland avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

.please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- After the shift between the device and the main girder is inserted on the pin and the pin card, after the shift is already used for rear jacking jacking, wind cable is tightened, the adjacent frame between the climbing frame is firmly rachel.

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- The climbing frame is the kind of iron that is assembled by a large construction site

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Advantages and disadvantages of climbing frame and floor type scaffoldPjal | browse 5789Recommended 2016-09-21 09:11:21 best answerClimbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. But it also has the disadvantage of fixed structure.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

Send your message to us

Auto-climbing Formwork systems for different constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords