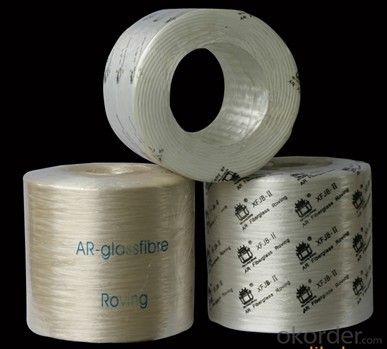

Fiberglass Woven Roving Mat - AR Spray Up Roving ZRO2 16.7%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of FRP Pipes

It is a Fiberglass roving produced by directly winding a certain number of individual fibers form the bushing without twist,it is coated with a silane-based size and is designed for reinforcing unsaturated polyester, epoxy,vinyl ester and phenolic resins. it is specially used to produce GRP pipes, pressure vessels, gratings and profiles and, when converted into woven roving, boats and chemical storage tanks, with filament winding, pultrusion and weaving process.

Specifications:

Glass Fiber Roving

Filament size:from 6mm~13mm

Tex count:550~2400tex

excellent dispersibility and alkali resistant

Applications:

beam,armrest,fence,and handrail, and it could be used in different industries like:Oil&Gas;Pulp&paper, Sewage water treatment;Power plant;Mining/refining;construction engineering;weaving and dyeing;pharmaceuticals;Food processing;Marine.

Packaging:

Cartons; pallets; customized packaging are welcomed

FAQ

1..Is your company a factory or trade company?

A:We have our own factory , we are on this business more than 10 years.

2.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

3.How long is the delivery time?

A:within 10-15 days after receiving deposit

- Q: What is the production process of FRP grille?

- Centrifugal casting process (which belongs to the fixed length method): in this process, the cut glass fiber reinforced materials and sand feeding fixed on the bearing steel mould, the catalyst of unsaturated resin is injected in the die end, the impregnated reinforcing material, under the action of centrifugal force, the replacement of resin fiber and fill in the air, thus producing a dense composite material without pores, due to the centrifugal force of the pipe inner surface layer with a smooth and polished resin is formed on the inner wall of pipe, curing at high temperature. The tube made of this method is also called glass fibre reinforced plastic sand inclusion tube.

- Q: Knowledges of bamboo fiber.

- So it needs special equipment for processing, but because the bamboo fiber is very short, the most notable feature is the environmental protection and decontamination capability. At present, it is mainly used in textile products. There is an association of bamboo fiber, where phyllostachys pubescens (General requirements for three years) is soaked and peeled, almost like paper-making.

- Q: What are the advantages of the glass?reinforced?plastics antenna? What is the difference between an ordinary antenna and a glass?reinforced?plastics antenna?

- waterproof. structure of the antenna is different from the conventional vertical antenna, but the principle is the same. They all are sealed.

- Q: How to produce glass steel?

- Material: Glass cloth, resin, curing agent tool: Glass?pane or polyester i thin?film process: According to the specifications for glass?reinforced?plastics, glass plane or polyester i thin film should be prepared and then you should tail glass cloth in accordance with requirements. At first, you should compound resin, and then you should put cloth that already have been tailed on the glass pane and cover it with compounded resin until its thickness meets requirements after removing all bubbles in it. After that, you should continue to cover it with polyester i thin film without bubbles and put a piece of glass on it if you want it more neat. A new product is ready after taking off the glass fiber reinforced plastics and trimming it carefully.

- Q: Model parameters of glass fiber reinforced plastic and glass fiber cloth

- The materials for strengthen are Medium, vinyl type and flame retardant, vinyl resin. There are many types of materials like phthalate, benzene, alkali free glass fiber roving, knitted mat etc.: polyester resin

- Q: What is rippled glass?

- Opaque glass.

- Q: Nominal interpretation of fiber reinforced concrete

- Mix composite materials with random and uniform distribution of short fiber in cement concrete, including steel fiber reinforced concrete. Technical specification for fiber reinforced concrete structures CECS.

- Q: What kind of knife can used to cut glass wool cloth?

- The mix proportion of epoxy resin and mortar is that 6101epoxy resin: ethylenediamine: cement: sand is equal to 100:15:8:200:500. 1 base dispose, 1)a vertical fissure is formed along the crack gouge, vertical cracks cut into 2 surface treatment, Siyou cloth with its surface sticking epoxy base fluid and glass silk cloth is used for surface treatment ( in which oil used is epoxy liquid, and cloth is glass?silk cloth). 1) process of glass silk cloth. Glass cloth generally usually made by alkali-free glass fiber is twistless roving woven cloth. Wetting agent are added in the production process of glass silk cloth. As wetting agent contains grease and wax which will impact the combination of epoxy base fluid and glass silk cloth, it is necessary to remove oil and wax on glass silk cloth in order to make epoxy base fluid immerse in glass fiber, improving the bonding effect. The method for removing wax and oil is to place glass silk cloth in boiling water containing with soda for an hour, then you should blanching it with clean water. the way to judge whether there is oil and wax on glass silk cloth is to touch and feel it. If you feel like it is not greasy, it is clean. After removing oil and wax, glass silk cloth losts its original white and brightness appearance and its weight also reduces correspondingly. 2) paste process. When pasting, you should brush epoxy resin base fluid evenly on the paste face, then you should brush the second layer with the same way.

- Q: waht about Plastic tray?

- Corrosion can not happen. Glass steel bridge use alkali glass fiber roving and its fabric as reinforcement material, welding or screwing connection, with the glass steel life for more than 50 years. Using unsaturated resin as matrix material, plastic colorant, glass steel bridge uses vinyl chloride (UPVC) resin as the main raw material. In fact, the material made for cable tray have something to do with the actual project. Glass steel belongs to high-quality composite materials, plus a proportion of the stabilizer, oil and other corrosive media, then it has antiseptic function and special filler. generally, plastic steel has 15-30years life. It is not very good for acid and salt, and it is not very ideal material for extrusion molding, corrosion protection and so on. Plastic tray has a price advantage, but the strength is not so good . After adding other mineral filler, long life, and then cured by heating, extruding into various sections of the hollow section processing, steel is steel profiles and the main chemical composition is PVC.

Send your message to us

Fiberglass Woven Roving Mat - AR Spray Up Roving ZRO2 16.7%

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords