AR Glassfiber Chopped Strand 16.5 as Manafacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15.6MTS

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

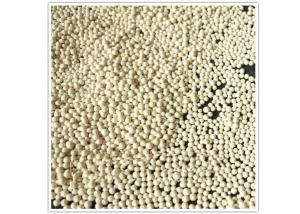

Specifications of AR Glassfiber Chopped Strand 16.5% as Manufacturer:

1.AR Fiberglass Chopped Strand for GRC

2.Good mechanical properties

3.Low static,good flowability

4.AR fiberglass

Description of AR Glassfiber Chopped Strand 16.5% as Manufacturer:

ARG chopped strand is designed to use in dry mix systems or other premixing processes GRC(Glassiber reinforced concret).Such as drainage channels, cable troughs, meter boxes, wall cladding panels or in architectural applications such as decorative screen walling, etc.

AR fiberglass chopped strands for GRC is with AR fiberglass roving for GRC to be chopped into certain length:

--ZrO2 content: 14.5%, 16.7%

--Filament diameter: 15um

--Yarn density: 2400tex

--Chopped length: 3mm, 6mm,12mm

Description of AR Glassfiber Chopped Strand 16.5% as Manufacturer:

ARG chopped strand is designed to use in dry mix systems or other premixing processes GRC(Glassiber reinforced concret).Such as drainage channels, cable troughs, meter boxes, wall cladding panels or in architectural applications such as decorative screen walling, etc.

ARC15-98-(3-30)mm ZrO2 14.5%

ARC13-76-(3-30)mm ZrO2 16.5%

Properties of AR Glassfiber Chopped Strand 16.5% as Manufactuerer:

Good liquidity and high integrity, Excellent alkali resistant and durability

Package of AR Glassfiber Chopped Strand 16.5% as Manufacturer:

20kgs/kraft bag, 50 bags/pallet, 20 pallets/20'FCL(on 2 levels), total net weight for 18 tons.

- Q: What is better brick patio or cement patio(ie cleaning it,cost)?

- Snowman obviously doesnt know how to pour concrete. Concrete is easier, brick looks better EDIT: if you dig your footings, add enough rebar and it's the right size(the rebar), it wont crack.

- Q: for patio what ratio cement +sand+gravel

- A properly designed concrete mixture will possess the desired workability for the fresh concrete and the required durability and strength for the hardened concrete. Typically, a mix is about 10 to 15 percent cement, 60 to 75 percent aggregate and 15 to 20 percent water. Entrained air in many concrete mixes may also take up another 5 to 8 percent.

- Q: he has had an epidural they are wanting to give another this coming week but it is not an answer . he is only 40 runs his own business, hands own. i do not know anything about this cement bones together i would appreciate any info or if anyone has had this done ,please let me know how it went, thank you

- You have not mentioned what it is your son wants and that's more important than what you want for him. My professional advice to him is if he's interested he can consult with his orthopod about his options. Mother, he's a grown man approaching middle age. Let him handle this. If, however, you wish to have information for yourself, run a search for spinal fusion.

- Q: I made extra cement that I don't want to throw out. I will be using it again in 22hrs, if I can. It got dark out before I could finish my job so my ? Is how to keep it ready for tomm. I'll be at work all day and can't keep adding water to it

- There is no way you can extend the life of concrete by 22 hours by adding water. The addition of water to temper, extend the workable life, of concrete significantly reduces the concrete strength. I have no idea how adding water to cement would react but I would guess it would be the same. By the way, cement is the soft stuff and concrete is the hard stuff. Once the initial water is added to a concrete mix it starts to set up. Concrete is said to cure, gain a very high percentage of its strength, in 28 days. A high percentage of the strength is gained between the 3rd and 7th days. Freezing the mix will not only ruin the concrete its ultimate strength would be very close to zero. A effects of a super plasticizer lasts for 30 to 60 minutes depending on the dosage and the concrete mix. After the effects wear off there is a rapid loss in workability. I can not see how this would help you. (That is for concrete super plasticizer I have no idea what a mortar plasticizer would do but I don't think it has ever been tried in a concrete mix.)

- Q: If your whole body, except for your head, were to be buried in cement is it possible to survive?

- No. The cement would harder, and your lungs couldn't move in and out. Your diaphragm couldn't move. You couldn't excrete waste either.

- Q: Hey, I was working with cement dust and it was windy, and ended up going everywhere - I mean my eyes, hair, and I breathed a lot of it in. Now Ive got a sore throat, heavy eyes, and it wont come out my clothes.How can I get it out clothes? And is it dangerous to breath in too much? Is it possible it mixed with sweat in my hair to form a paste? it feels funny! Health affects? thanks for any help :-)

- Go to a hospital and get your lungs flushed out or something.

- Q: How is cement made out of?

- Chalk and clay tumbled in a huge drum with lots of heat

- Q: How do I jack out a 5 ft. high garage cement wall that is bowing in. It keeps getting worse?

- ooh dear, the problem is the foundation upon which it sits, also sounds like there might be contributing factors like tree roots pushing up from underneath causing this damage, I wouldn't advise you to try and fix this on your own get a building inspector out, you may be able to claim insurance for it,if you do it yourself you will forfeit this right.

- Q: please i need advantages and dissadvantages, like how carbide is more expensive, and how high speed steel is resharpable.also a website for references would be nice, thanx in advance.

- Generally, cemented carbide is harder than high speed steel. To last the longest and provide the best cuts It also requires different rake angles relative to the material being cut. A negative rake angle is better with cemented carbide cutting tools and a positive rake angle is better for high speed cutting tools. The material being machined is also a factor in the best rake angle.

- Q: Need to remove cement like glue from painted metal. Any house hold items i can use or do i have to buy a glue remover. i.e. rubbing alcohol , cleaners ect. Thanks

- You cant do that because cemert dries really hard so if you jack hammer i suggust not to do because it drys really hard

1. Manufacturer Overview

| Location | Hubei,China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Southern Europe 10% Northern Europe 10% Central America 10% Western Europe 10% Eastern Asia 10% Mid East 30% Africa 20% |

| Company Certifications | N/A |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai PORT |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | 示范:High;Average |

Send your message to us

AR Glassfiber Chopped Strand 16.5 as Manafacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15.6MTS

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords