Aluminum Sheets in Wyoming - Aluminum Sheet and Mill Finished Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description

Aluminium atoms are arranged in a face-centered cubic (fcc) structure. Aluminium has a stacking-fault energy of approximately 200 mJ/m2.

Aluminium is a good thermal and electrical conductor, having 59% the conductivity of copper, both thermal and electrical, while having only 30% of copper's density. Aluminium is capable of being a superconductor, with a superconducting critical temperature of 1.2 Kelvin and a critical magnetic field of about 100 gauss (10 milliteslas).

2.Chemical

Corrosion resistance can be excellent due to a thin surface layer of aluminium oxide that forms when the metal is exposed to air, effectively preventing further oxidation.The strongest aluminium alloys are less corrosion resistant due to galvanic reactions with alloyed copper.This corrosion resistance is also often greatly reduced by aqueous salts, particularly in the presence of dissimilar metals.

In highly acidic solutions aluminium reacts with water to form hydrogen, and in highly alkaline ones to form aluminates— protective passivation under these conditions is negligible. Also, chlorides such as common sodium chloride are well-known sources of corrosion of aluminium and are among the chief reasons that household plumbing is never made from this metal.

However, owing to its resistance to corrosion generally, aluminium is one of the few metals that retain silvery reflectance in finely powdered form, making it an important component of silver-colored paints. Aluminium mirror finish has the highest reflectance of any metal in the 200–400 nm (UV) and the 3,000–10,000 nm (far IR) regions; in the 400–700 nm visible range it is slightly outperformed by tin and silver and in the 700–3000 (near IR) by silver, gold, and copper.

3. Specification

ALLOY: AA1*** (AA1050,AA1060,AA1070,AA1100 etc.)

AA3*** (AA3003,AA3004,AA3005,AA3105 etc.)

AA5*** (AA5052,AA5083,AA5754 etc)

AA8*** (AA8011,AA8006 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: 0.2mm-100mm

WIDTH: 30mm-1700mm

STANDARD: GB/T 3880-2006

Special specification is available on customer's requirement

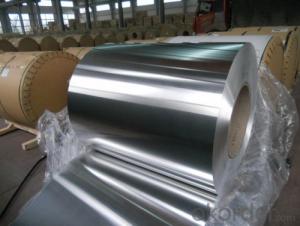

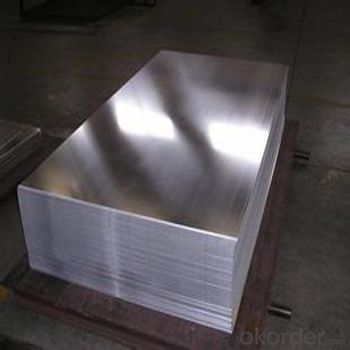

4.Picture

5.FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the cost of aluminum sheets compared to other metals?

- The cost of aluminum sheets is generally lower compared to other metals such as stainless steel or copper. Aluminum is a widely available and abundant material, which contributes to its relatively affordable price in comparison to other metals.

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves creating holes or punctures in a material, and it can be done on various types of metals, including aluminum.

- Q: Are aluminum sheets suitable for decorative purposes?

- Aluminum sheets are perfect for decorative purposes. This material is incredibly versatile and can easily be shaped and designed, making it ideal for adding decoration. You can cut, bend, and mold aluminum sheets into various patterns, providing endless possibilities for creating decorative elements. Additionally, you can coat or paint the sheets in different colors and finishes to enhance their aesthetic appeal. Moreover, aluminum is both lightweight and durable, making it suitable for indoor and outdoor decorative use. It is resistant to corrosion, ensuring that your aluminum decorations will maintain their appearance and last for a considerable amount of time. Overall, aluminum sheets offer a plethora of design options and practical benefits, making them an outstanding choice for decorative purposes.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: What are the different methods of heat treating aluminum sheet?

- There are several methods of heat treating aluminum sheet, each with its own purpose and desired outcome. Some of the common methods include: 1. Solution Heat Treatment: This process involves heating the aluminum sheet to a specific temperature, typically between 900-1000°F (480-540°C), and holding it at that temperature for a set amount of time. This helps dissolve any soluble alloying elements present in the aluminum, resulting in a more uniform structure. 2. Quenching: After the solution heat treatment, the aluminum sheet is rapidly cooled by quenching in water, oil, or air. This rapid cooling helps lock in the desired microstructure and properties, such as increased strength and hardness. 3. Aging: Once quenched, the aluminum sheet is subjected to an aging process, which involves heating it to a lower temperature, typically between 250-450°F (120-230°C), and holding it there for a specific duration. This allows for the precipitation of fine particles within the aluminum matrix, improving its strength and hardness even further. 4. Precipitation Hardening: This method is used for certain aluminum alloys, such as 2000 and 7000 series, which respond well to precipitation hardening. It involves a combination of solution heat treatment, quenching, and aging, resulting in a highly strengthened and durable aluminum sheet. 5. Annealing: Annealing is a heat treatment process used to soften the aluminum sheet and relieve any internal stresses. It involves heating the sheet to a specific temperature, usually around 600-700°F (315-370°C), and then slowly cooling it. This helps improve the formability and machinability of the aluminum. 6. Stress Relieving: This method is similar to annealing but is specifically used to reduce residual stresses in the aluminum sheet after fabrication. It involves heating the sheet to a temperature below its annealing temperature and then slowly cooling it. Overall, the choice of heat treatment method for aluminum sheet depends on the desired properties, alloy composition, and intended application. Each method offers distinct advantages and can significantly enhance the mechanical and physical properties of the aluminum sheet.

- Q: This question asks for the current market price of aluminum sheets.

- <p>The price of aluminum sheets in the market can vary significantly based on factors such as grade, thickness, quantity, and market demand. As of my last update, the price per ton of aluminum was fluctuating around $2,000 to $3,000 USD, but this is subject to change. For the most accurate and up-to-date pricing, it's best to check with suppliers or commodity exchanges, as prices can shift daily due to global economic conditions and supply chain dynamics.</p>

- Q: What are the physical properties of aluminum?

- Some physical properties of aluminum include its silvery-white appearance, low density, high thermal conductivity, and good electrical conductivity. It has a melting point of 660.32°C (1220.58°F) and a boiling point of 2519°C (4566°F). Aluminum is also malleable, ductile, and highly corrosion resistant.

- Q: Are aluminum sheets suitable for use in electrical applications?

- Aluminum sheets are indeed appropriate for utilization in electrical applications. The reason for this appropriateness lies in aluminum's remarkable ability to conduct electricity. Its exceptional conductivity enables the efficient transmission of electrical current. In fact, aluminum sheets are frequently employed in electrical applications including power transmission lines, electrical wiring, and electrical enclosures. Furthermore, aluminum's lightweight nature facilitates easier handling and installation. It also possesses resistance against corrosion, ensuring prolonged durability and reliability within electrical systems. Nevertheless, it is crucial to acknowledge that aluminum exhibits lower conductivity in comparison to copper. Consequently, compensating for this disparity may require the use of larger gauge sizes. In summary, aluminum sheets serve as a feasible and cost-effective choice for a variety of electrical applications.

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved. Etching or engraving on aluminum sheets is a process that involves removing some of the material from the surface using acid or a high-powered laser. This can be done to create intricate designs, patterns, or even text on the aluminum sheet. The etching or engraving process can be used for various applications, such as signage, decorative pieces, or industrial parts. The resulting etched or engraved design on the aluminum sheet can be further enhanced by adding color or other finishes to create a desired look.

Send your message to us

Aluminum Sheets in Wyoming - Aluminum Sheet and Mill Finished Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords