Aluminum Sheets in Iowa - Aluminum Sheet, Aluminum Plate, Cheap Price Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.specification

material: | Alloy or not | ||

thickness: | 1,3 series | 0.3-9.5mm | |

5series | 0.5-150mm | ||

6 series | 5-150mm | ||

7series | More than 6mm | ||

width: | 1,3 series | 900-1500mm | |

5 series | 900-1500mm | ||

6 ,7series | As your request | ||

Circulation size: (width*length)

| 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm | ||

Usage : | Boat, plane, building, packaging, machine…. | ||

MOQ | 3 tons | ||

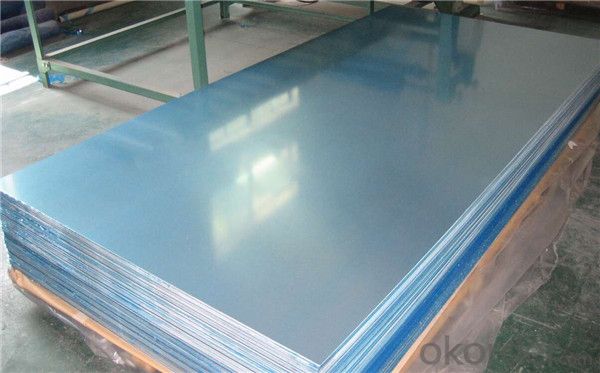

2.product show

Dear Customer, why do I have the confidence to let you buy our product ?

♥strict chemical composition , good hardness high safety performance

♥Oxide film thickness, corrosion resistance

♥Standard aluminum closed time, no rust

♥smooth surface, no burrs

Our VS others

3.shipping:

20~25 working days & send samples:2--3 days after received your advance payment

Mode of transport | advantage | disadvantage | advice |

Express delivery | Fast(3—6days ),door to door wide area coverage | Volume & weight restricted | Good for small cargo |

Sea transpoet | Cheapest volume unlimited | Long sailing time influenced by climate and port conditions | Bulk cargo loose time |

Air transport | Fast(4—5days) simple packaging | The most expensive volume restrict | For valuable cargo urgent need |

Railway | Big volume more expensive | Tracking difficult transit organization may cause delay | Preferred in central Asia |

4.Product photos

- Q: how much should the current be adjusted when I use pulse aluminum welding machine to weld 0.7 aluminum sheet?

- 60-70A current is enough for 0.7 aluminum sheet,the key poiny is that the thin sheet should be bonded with iron sheet or other assistant cooling device when you weld it, or it will be burned through.

- Q: Can aluminum sheets be used for bus bodies?

- Indeed, bus bodies can be constructed using aluminum sheets. Aluminum, renowned for its lightweight and durable qualities, is frequently utilized in the fabrication of bus bodies. Its exceptional strength-to-weight ratio renders it an optimal selection for bus manufacturers, as it enhances fuel efficiency and expands payload capacity. Moreover, aluminum exhibits remarkable resistance to corrosion, a valuable attribute for vehicles perpetually confronted with diverse weather conditions. Additionally, aluminum can be effortlessly shaped and fabricated, enabling the production of intricate forms and designs. Consequently, aluminum sheets are widely favored for bus bodies owing to their robustness, lightness, resistance to corrosion, and adaptability.

- Q: Are the aluminum sheets suitable for marine vessel construction?

- Marine vessel construction greatly benefits from the utilization of aluminum sheets. With its exceptional corrosion resistance properties, aluminum proves itself as the ideal material for saltwater environments. Its lightweight nature combined with its strength strikes a perfect balance between durability and weight reduction, resulting in improved fuel efficiency and increased payload capacity. Moreover, shipbuilders favor aluminum due to its ease of fabrication, welding, and repair. Its high strength-to-weight ratio and ability to withstand extreme temperatures also render it suitable for various marine applications, including hulls, decks, superstructures, and other structural components. All in all, the use of aluminum sheets in marine vessel construction presents numerous advantages, establishing it as a favored choice within the maritime industry.

- Q: How do you prevent oxidation of exposed edges of aluminum sheets?

- There are several effective methods available to prevent oxidation of exposed edges on aluminum sheets: 1. Applying a protective coating is a commonly used approach. Various types of coatings like paint, lacquer, or specialized protective coatings designed for aluminum can be used. These coatings act as a barrier, preventing contact between the aluminum, oxygen, and moisture, which are the main causes of oxidation. 2. Anodizing is another option. This involves subjecting the aluminum sheets to an electrolytic process, creating a controlled and thick layer of oxide on the surface. This layer acts as a protective barrier against oxidation and offers additional benefits like improved corrosion resistance and enhanced aesthetics. 3. Proper storage and handling practices are crucial. Aluminum sheets should be kept in a dry and well-ventilated area, away from moisture and humidity. It is important to avoid placing them directly on the ground or other surfaces that may expose them to moisture. Additionally, wearing gloves during handling can minimize the transfer of oils from the skin, which can accelerate oxidation. 4. Regular cleaning and maintenance play a significant role in preventing oxidation. Removing dirt, grime, and other contaminants from the surface is essential as they contribute to the oxidation process. Mild soaps or detergents and a soft cloth or sponge can be used for cleaning. Thoroughly drying the sheets after cleaning is important to eliminate any remaining moisture. By implementing these preventive measures, the oxidation of exposed edges on aluminum sheets can be effectively minimized. This ensures their durability and preserves their aesthetic appeal.

- Q: There seems to be a load of buzz out there regarding the use of aluminum pots and pans. They apparently may cause Alzheimer’s or bone degeneration in women. I have some cast iron pans that I use when ever possible but they are not always practical. I’d like some of you kitchen pros to give me some sound advice regard the use of aluminum in the home kitchen. I know they are used in food service organizations.... I look forward to some informative replys.Thanks in advance.

- I try to avoid cooking acidic ingredients in aluminum such as tomato sauce. If you take a piece of aluminum foil and lay it on tomato sauce the sauce will begin to eat holes in the aluminum. Boiling water for the pasta for that sauce seems a lot less risky. There have been links between aluminum and Alzheimer's so probably better to be safe than sorry. p.s. I usually bake large quantities of tomato sauce in the oven in stainless steel hotel pans. No scorching or aluminum. Invest in a few stainless steel pots for sauces.

- Q: Are aluminum sheets resistant to staining?

- Yes, aluminum sheets are resistant to staining. Aluminum has a natural oxide layer that forms on its surface when exposed to air. This oxide layer acts as a protective barrier, preventing staining and corrosion. However, it is important to note that prolonged exposure to certain chemicals or acidic substances can still cause discoloration or staining on aluminum sheets. Regular cleaning and maintenance are recommended to preserve the appearance and longevity of aluminum sheets.

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: Hello,Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum?Thanks!

- you can use the standard metal cut-of wheels as a last resort...but the low melting point of aluminium and granularity of lower grades of alu mean that you disc will clog up, so it doesn't cut efficiently, and you will get a messy cut with a lot of slag around the cut which then needs a lot of filing to tidy up. Special cut off wheels for cutting aluminium are available. You can cut alu with a circular saw as its nor harder than say oak... but again because of the low melting point you need a saw blade designed for cutting aluminum. Finally cutting aluminium with a circular saw requires that you use the right amount of force, to hard and you'll get a rought cut or stall the motor, too soft and you cover the blade in melted alu.

- Q: Is it possible to install aluminum sheets on an existing roof structure?

- <p>Yes, aluminum sheets can be installed on existing roofs. This process typically involves removing the old roofing material and ensuring the roof structure is sound. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them a popular choice for roof installations. They can be installed over a solid substrate, such as plywood or metal decking, and often require a proper underlayment to ensure watertightness. It's important to follow manufacturer guidelines and local building codes when installing aluminum sheets on an existing roof. Professional installation is recommended to ensure the roof's integrity and longevity.</p>

- Q: How much do aluminum sheets typically weigh?

- Aluminum sheets typically weigh between 1.9 to 3.4 grams per square centimeter, depending on the thickness and size of the sheet. The weight of aluminum sheets can vary significantly based on their dimensions and gauge. Thinner sheets generally weigh less, while thicker sheets tend to be heavier. It is important to note that the weight of aluminum sheets can also be influenced by factors such as the alloy used and any additional coatings or treatments applied to the surface. Therefore, it is advisable to consult the specific product specifications or reach out to the manufacturer for accurate weight information.

Send your message to us

Aluminum Sheets in Iowa - Aluminum Sheet, Aluminum Plate, Cheap Price Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords