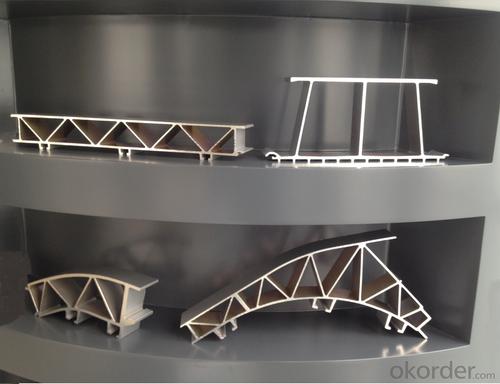

Aluminum Pipes for Subway Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Subway; 2. Drilling; 3. Welding; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: The same size or different specifications of the square aluminum tube, T how to connect more beautiful ah?!

- According to the precision points: ordinary aluminum tube and precision aluminum tube, in which the precision aluminum tube generally needs to be processed after extrusion, such as cold drawn, fine drawn, rollingBy thickness: ordinary aluminum tube and thin-walled aluminum tubePerformance: corrosion resistance, light weight.

- Q: Is the tube of LED lamp all plastic tube well or half plastic half aluminium tube?

- All plastic tube is one of the most widely used early, because the main use of non isolated power supply, in order to avoid electric shock problems, so I hope to use more plastic tube. Which is used with Phi 5 straw hat tube LED. The fluorescent lamp is the biggest problem due to the heat radiating, all sealed in the tube, unable to escape, life is very serious, coupled with the straw tube had life is very short, less than 2000 hours on the bad.Semi plastic half aluminum LED fluorescent lamps sold on the market are basically the half PC Aluminum Alloy, in the half light of the use of plastic in need not pervious to light and need the half cooling on the use of Aluminum Alloy.

- Q: Such questions. Recently prepared to buy an umbrella with the baby, too heavy to hold for a long time can not stand. Taobao took a look, the style is colorful. I saw 3 stalls tent, but there are two kinds of pipes, do not know what kind of practical. Steel pipe should be relatively strong and durable, the aluminum tube is characterized by light, but worried that the baby sit on top of instability. How do moms choose?

- Aluminum tubes are mainly divided into the followingAccording to the shape of: square tube, round tube, pattern tube, special-shaped tubeIt can be divided into seamless aluminum tube and common extrusion pipe according to extrusion methodAccording to the precision points: ordinary aluminum tube and precision aluminum tube, in which the precision aluminum tube generally needs to be processed after extrusion, such as cold drawn, fine drawn, rollingBy thickness: ordinary aluminum tube and thin-walled aluminum tubePerformance: corrosion resistance, light weight.

- Q: Can aluminum pipes be used for wastewater pipelines?

- Yes, aluminum pipes can be used for wastewater pipelines. Aluminum is corrosion-resistant and lightweight, making it a suitable material for wastewater transportation. However, the choice of pipe material depends on various factors such as the type of wastewater, its temperature, and the surrounding environment. It is recommended to consult with a professional engineer or plumbing expert to determine the most appropriate pipe material for a specific wastewater application.

- Q: Villa reconstruction, taking into account the importance of water supply and drainage, to choose some good pipe. I looked at the Sorbonne piersa, HSBC, Kim these tubes inside, so some of the pipe plastic pipe and plastic pipe PPR divided into different categories such as pipes, these pipes in the end what is the difference? Which is better?

- The first two can be bent, the connector needs to use copper pieces. The latter can not bend, the straightness is pretty good, the connecting parts are made of double hot melt PPR parts, and the three can withstand the temperature for a long time to reach 95 degreesWhile the former two is different, RPAP5 is a high technology product butt welding, endurance is more uniform, the price is higher than the ordinary plastic pipe (welding), relatively RPAP5 butt welding aluminium plastic pipe, the effect is better than the other two kinds of tubes.

- Q: Can aluminum pipes be used for electrical grounding systems?

- Indeed, aluminum pipes are suitable for electrical grounding systems. Due to their excellent conductivity and minimal electrical resistance, aluminum is frequently employed as a material for grounding. This choice proves both effective and economical as it allows for efficient dissipation of electrical charges and facilitates the safe flow of electrical currents into the ground. Nevertheless, to uphold the integrity of the grounding system, it is imperative to employ appropriate installation methods and connectors to prevent corrosion. Moreover, adherence to local electrical codes and regulations is crucial when opting for and installing aluminum pipes for electrical grounding objectives.

- Q: What are the different threading options for aluminum pipes?

- The different threading options for aluminum pipes include NPT (National Pipe Thread), NPS (National Pipe Straight), BSP (British Standard Pipe), and metric threading. These threading options allow for compatibility with various fittings and connections in plumbing, gas, and fluid transfer applications.

- Q: Can aluminum pipes be used for irrigation sprinkler systems?

- Yes, aluminum pipes can be used for irrigation sprinkler systems. Aluminum pipes are lightweight, durable, and resistant to corrosion, which makes them a suitable choice for irrigation systems. They are also easy to install and can withstand high-pressure water flow. Additionally, aluminum pipes have a longer lifespan compared to other materials, such as PVC or galvanized steel, which makes them a cost-effective option for irrigation systems. However, it is important to consider the specific requirements of the irrigation system and consult with a professional to ensure that aluminum pipes are the best choice for your specific needs.

- Q: Can aluminum pipes be used for solar panel frames?

- Yes, aluminum pipes can be used for solar panel frames. Aluminum is a popular choice for solar panel frames due to its lightweight nature, corrosion resistance, and strength. It provides a durable and reliable structure that can withstand various weather conditions. Additionally, aluminum is easy to work with and can be easily shaped and molded to meet specific design requirements. Its high thermal conductivity also helps in dissipating heat generated by the solar panels, improving their overall performance. Overall, aluminum pipes are a suitable and commonly used material for solar panel frames.

- Q: Can aluminum pipes be used for geothermal heating systems?

- Indeed, geothermal heating systems can make use of aluminum pipes. The popularity of aluminum in the construction of geothermal heat exchangers is due to its remarkable heat transfer capabilities. With its high thermal conductivity, aluminum effectively transfers heat from the earth to the fluid flowing within the pipes. Moreover, aluminum is renowned for being lightweight, resistant to corrosion, and possessing a long lifespan, rendering it a durable and economical choice for geothermal heating systems. Nevertheless, it is crucial to insulate the aluminum pipes appropriately to minimize heat loss and optimize the system's efficiency.

Send your message to us

Aluminum Pipes for Subway Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords