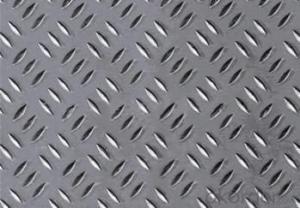

Aluminum Painted Embossed Diamond Aluminum Sheet - Diamond Embossed Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction:

Electrodes in the aluminum foil, aluminum foil wool, the curtain with aluminum belt, 3105, 1235, 1050, 1145, 1200, 8011 o, H22, H24, H26, H180.20 ~ 0.80 mm, width 800 ~ 1900

Non-slip aluminum sheet 7. All kinds of decorative pattern, five reinforcement, the pointer shape and decorative pattern, in addition, produce 3003 orange peel pattern aluminum coil.

Goods of Description:

1. Roll casting slab billet 1060105 0107 0110 0300 3310, 5, 3 A21, LF21, 5052801 1, etc.

2. Various USES aluminum plate, various USES aluminium strip, processing customized according to user requirements.

3. The cable foil, cable aluminum belt, cable coated with aluminum foil, 8011 o0. 12 ~ 0.20 mm wide, 50 ~ 1300106 0 O0.5 ~ 2.0 mm wide, 50 ~ 1300.

4. Lu: su composite work aluminum strip, 8011 o0. 16-10-1200 - mm * 0.3 mm * l.

5. Aluminium and aluminium alloy curtain wall construction, decoration, 1070, 1070, 1050, 3003, 3 a21h16, H14, H26, H181.5 ~ 4.0 mm wide, 1000 ~ 1000 long and 1000 ~ 6000.

Application:

suitable for wastewater treatment, water, power plant in other industries outside, checkered plate is used for mechanical antiskid and interior decoration, prevent slippery, wharf, diaoyutai state guesthouse, workshop, at the bottom of the car, cement floor, the door of the hotel, etc.

- Q: What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available, including plain, embossed, perforated, and painted aluminum sheets.

- Q: Are 101 aluminum sheets suitable for decorative purposes?

- Yes, 101 aluminum sheets are suitable for decorative purposes. They offer a sleek and modern look, are lightweight, and can be easily customized or shaped to create various decorative elements.

- Q: What are the typical thickness options for aluminum sheets?

- The typical thickness options for aluminum sheets range from 0.006 inches to 0.25 inches, depending on the specific application and requirements.

- Q: Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q: What specific considerations or precautions need to be taken into account when working with thin aluminum sheets?

- <p>When working with thin aluminum sheets, it's important to handle them carefully to prevent denting or bending. Use gloves to avoid oils and moisture from hands that can cause corrosion. Ensure proper ventilation when cutting or shaping to avoid inhaling aluminum dust. Use sharp tools to minimize the risk of tearing or marring the surface. Also, consider the specific alloy's properties, as different aluminum alloys have varying strengths and malleabilities. Always follow safety guidelines and use appropriate protective equipment.</p>

- Q: why can't aluminum sheet burn after polishing?

- because aluminum will rapidly formulate dense oxide film once being exposed in air, oxide film will generate after polishing, it can't burn.

- Q: How do aluminum sheets compare to other metals?

- Aluminum sheets have several advantages when compared to other metals. Firstly, aluminum is very light in weight, making it an ideal choice for applications where weight is a concern, such as in the aerospace industry. Additionally, aluminum is highly resistant to corrosion, which means it can withstand exposure to moisture and chemicals without deteriorating. This makes aluminum sheets suitable for outdoor use and in environments with high humidity or corrosive substances. Moreover, aluminum has excellent conductivity, both thermal and electrical. This makes it a popular choice for heat sinks, electrical enclosures, and other applications that require efficient heat dissipation or electrical conduction. Furthermore, aluminum sheets can be easily shaped and formed, giving them versatility in various manufacturing processes. They can be bent, cut, welded, and machined with relative ease, making them highly adaptable to different design specifications. In terms of cost, aluminum is generally more affordable compared to other metals like steel or copper. This makes it a cost-effective option for many industries, especially for large-scale production or projects with budget constraints. However, it is important to note that aluminum sheets may not be suitable for applications that require high strength or extreme temperatures, as aluminum has lower strength and melting point compared to certain other metals. In such cases, metals like steel or titanium may be more appropriate. In summary, aluminum sheets offer a combination of lightweight, corrosion resistance, good conductivity, versatility, and affordability that makes them a preferred choice in many industries. However, the specific requirements of a project or application should be considered to determine if aluminum sheets are the best fit or if another metal would be more suitable.

- Q: What is the density of the 1100 aluminum plate?

- 1100 aluminum density is fand 2.7g/cm.1100 for industrial pure aluminum, aluminum content (mass fraction) of 99%, can not be enhanced by heat treatment. With high corrosion resistance, electrical conductivity and thermal conductivity, and its small density, good plasticity, through pressure processing can produce all kinds of aluminum, but the strength is low.

- Q: How does the formability of aluminum sheet vary with different alloys?

- Variations in chemical composition and mechanical properties result in significant differences in the formability of aluminum sheet among different alloys. To enhance specific characteristics like strength, corrosion resistance, and formability, aluminum alloys are typically combined with elements such as copper, manganese, magnesium, and zinc. Aluminum alloys like the 1xxx series (pure aluminum) and the 3xxx series (manganese alloyed) are highly formable and commonly used for deep drawing applications. These alloys can be shaped into complex forms without cracking or tearing. In contrast, alloys with higher strength properties, such as the 2xxx series (copper alloyed) and the 7xxx series (zinc alloyed), generally have reduced formability. Although these alloys are often used in structural applications where strength is crucial, they require careful handling and processing to avoid defects during forming. Alloys in the 5xxx series (magnesium alloyed) offer a good balance of formability and strength. They are widely used in industries like automotive and aerospace, as they can be easily formed into different shapes while providing sufficient strength and corrosion resistance. It's important to note that the formability of aluminum sheet is not solely determined by the alloy composition. Other factors such as sheet thickness, forming temperature, and the specific forming process employed (e.g., deep drawing, bending, stretching) also influence formability. These factors interact with alloy properties to affect the formability characteristics of aluminum sheet. Therefore, careful selection of the appropriate alloy and process parameters is essential to achieve the desired formability for specific applications.

- Q: This question asks for methods to protect aluminum sheets from rusting when exposed to outdoor conditions.

- <p>To prevent rusting of aluminum sheets in outdoor environments, it's crucial to understand that aluminum doesn't rust but forms a thin layer of aluminum oxide, which can darken the surface. To protect aluminum sheets, use protective coatings such as clear anodizing, which enhances the natural oxide layer, or apply a paint or powder coating. Regular cleaning and maintenance can also help in removing dirt and grime that can accelerate the oxidation process. Additionally, using stainless steel fasteners and avoiding contact with dissimilar metals can help prevent galvanic corrosion.</p>

Send your message to us

Aluminum Painted Embossed Diamond Aluminum Sheet - Diamond Embossed Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords