Big Aluminum Foil - Aluminum Foil-Paper Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of Aluminum Foils, Aluminum Foil-paper

In North America, aluminium foil is known as aluminum foil. It was popularized by Reynolds Metals, the leading manufacturer in North America. In the United Kingdom and United States it is, informally, widely called tin foil, for historical reasons (similar to how aluminum cans are often still called "tin cans").Metallised films are sometimes mistaken for aluminium foil, but are actually polymer films coated with a thin layer of aluminium. In Australia, aluminium foil is widely called alfoil.

2.Why you choose us?

Our quelity and service is best in China!

3.Aluminum Foils, Aluminum Foil-paper Specification and Application

ALUMINIUM FOIL

ALLOY:AA1***

AA3***

AA8***

TEMPER: O H14 H16 H18 H22 H24 H26

THICKNESS: 0.006MM-0.20MM

WIDTH: 200MM-1600MM

COATING: HSL/PRIMER

STANDAR: GB/T 3198-2003

LIGHT GAUGE ALUMINUM FOIL

application:cigarette package, aseptic package, pouches, sachets

alloy:1235/8011/8079

temper:O

thickness&tolerance:0.006mm-0.009mm (±6%)

width&tolerance: 200mm-1650mm (±1mm)

mehanical properties: tensile strength (U.T.S)≥40Mpa, elongation≥1%

standard: GB/T3198 / ASTM-B209 /EN 546

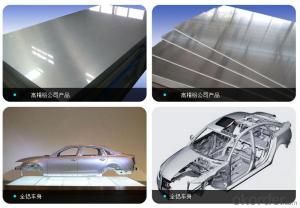

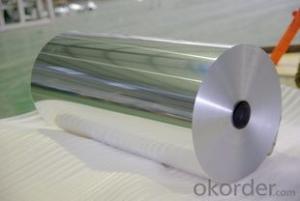

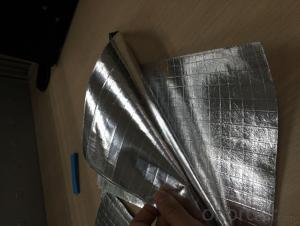

4.Aluminum Foils, Aluminum Foil-paper Pictures

5.Aluminum Foils, Aluminum Foil-paper FAQ

1)How about our payment term?

LC and TT and other.

2)Which country can we supply?

All around the world!

Production Flow of Hot Rolled Checkered Steel Plate:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

- Q: I know aluminium forms and oxide layer when in airIf I remove the oxide layer some how, say I do it underwater with wet and dry paper, would the oxide stay off and aluminium start reacting with the water to form aluminium hydroxide and hydrogen? My aim is to form hydrogenI dont have access to industrial chemicals like gallium which I would prefer.

- funny i use the same things they work for me keep on using them you'll get used to them it takes lots of practice

- Q: I have naturally ash blonde hair but I've highlighted it for the past 2 yearsMy roots are starting to grow out again and I was looking at the Coloure Experte kit from Loreal that is 2 steps, you do a base color first, dry it and then do highlightsThe only problem is I'm scared the highlighting cream might drip onto other parts of my hair so my question is: Can I apply the highlighting cream to a strand of hair and then cover it with aluminum foil while it processes to keep it from dripping on the rest of my hair, or will the hurt the whole highlighting process?Thanks!

- Some hair products are not to be used with metals so I can only suggest that if you want to seperate the hair then I would use clingfilm instead of foilHope this helps.s

- Q: Maybe with chicken and bacon and almonds and goat cheese and some spinach and lettuceI KNOW that this may be fattening, I don't want to lose weight I just want to incorporate salad to my diet.

- Strawberry Spinach Salad Ingredients 2 tablespoons sesame seeds 1 tablespoon poppy seeds 1/2 cup white sugar 1/2 cup olive oil 1/4 cup distilled white vinegar 1/4 teaspoon paprika 1/4 teaspoon Worcestershire sauce 1 tablespoon minced onion 10 ounces fresh spinach - rinsed, dried and torn into bite-size pieces 1 quart strawberries - cleaned, hulled and sliced 1/4 cup almonds, blanched and slivered Directions In a medium bowl, whisk together the sesame seeds, poppy seeds, sugar, olive oil, vinegar, paprika, Worcestershire sauce and onionCover, and chill for one hourIn a large bowl, combine the spinach, strawberries and almondsPour dressing over salad, and tossRefrigerate 10 to 15 minutes before serving or Fruity Curry Chicken Salad Ingredients 4 skinless, boneless chicken breast halves - cooked and diced 1 stalk celery, diced 4 green onions, chopped 1 Golden Delicious apple - peeled, cored and diced 1/3 cup golden raisins 1/3 cup seedless green grapes, halved 1/2 cup chopped toasted pecans 1/8 teaspoon ground black pepper 1/2 teaspoon curry powder 3/4 cup light mayonnaise Directions In a large bowl combine the chicken, celery, onion, apple, raisins, grapes, pecans, pepper, curry powder and mayonnaiseMix all togetherServe! or Candied Walnut Gorgonzola Salad Ingredients 1/2 cup walnut halves 1/4 cup sugar 3 cups mixed greens 1/2 cup dried cranberries 1/2 cup crumbled Gorgonzola cheese 1 tablespoon raspberry vinaigrette 1 tablespoon white vinegar 1 tablespoon olive oil Directions Place walnuts and sugar in a skillet over medium heat, stirring constantly until the sugar dissolves into a light brown liquid and coats the walnutsRemove walnuts from skillet, and spread them out on a sheet of aluminum foil to coolPlace in a large salad bowl the mixed greens, cranberries, cheese, vinaigrette, vinegar, and olive oilToss gently; add candied walnuts, and toss again hope this helps!!!

- Q: i wanna remove the anodizing on my paintball gunits all aluminum parts but i wanna be sure that nothing bad will happen if i remove the anodizing.

- follow the recipe, cook it, then remove from the oven, let it go completely cold, then use foil over the dish and wrap it in cling filmfreeze it in the coldest part of the freezerwhen you want to eat it you then need to defrost it in the fridge over night, and just reheat in the oven prior to eating it!

- Q: no rolling paper.what to use?

- an aluminum can.dent the side in and use a fork to poke holes in it.little ones or it will fall in.use the drink hole to inhale.or use a toilet paper roll (empty of course) and cut a circle out and place aluminum foil over the hole with holes poked in it and inhale from the other end.happy smoking.lol

- Q: How to make corn nuggets?

- Ingredients 1 (11 ounce) can creamed corn 1 (11 ounce) can whole kernel corn, drained 1/2 cup yellow cornmeal 1/2 cup all-purpose flour 1 egg white 2 tablespoons milk salt and pepper to taste 3 cups vegetable oil for deep frying Directions In a medium bowl, stir together the creamed corn and drained whole kernel cornLine a baking sheet with aluminum foil, and coat with vegetable oil or cooking sprayDrop spoonfuls of the corn mixture onto the sheet, and freeze until firm, about 3 hoursHeat one inch of oil to 350 degrees F (175 degrees C) in a large deep skillet, or fill a deep-fryer with oil as directed by the manufacturerMix together the cornmeal, flour, egg white, milk, salt and pepper in a medium bowlDip frozen corn nuggets in the batter, and quickly fry in hot oil until golden brownRemove to paper towels to drain.

- Q: why do you need heat blocks in the process of wire bonding an ic? what's the purpose of hte heat blocks?

- There are several processes use to connect IC's during packagingTwo are ultrasonic bonding of aluminum wires, and thermosonic welding of gold wiresUltrasonic bonding is used for aluminum wireThe wire is pressed against an aluminum pad on the IC and moved rapidly back and forthThis breaks the Aluminum oxide off both the wire and the padOnce you have clean metal, stop vibrating the wire, and they weld nicelyFor gold wires, thermosonic welding is usedJust rubbing the wire against the pad will not reliably remove the aluminum oxide from the padThe gold wire, of course, does not significantly oxidizeHeating the IC with a heater block warms it sufficiently to weaken the bond between the aluminum pad and its oxide, so the oxide can break offThen, the ultrasonics weld the gold wire to the pad in a somewhat equivalent manner to the aluminum U/S bond mentioned above.

- Q: I put a bag over it hoping it would stop the signal but it doesn't workHow do I block it, do I need something thicker?

- you need something radiopaque like aluminum foil, try that

- Q: According to Reader's Digest, I can:asprinkle the inside of the whole fish with salt, pepper and lemon juice, then place on a greased grill and brown carefully on both sidesBaste with melted butter and white wine.bsprinkle inside with same mixture as above and then place in a special hinged grillBaste with a soya sauce basting mix or lemon juice, oil and tarragonFlip sides after browning on each.cBaste with oil mixed with lemon juice, sugar and white wine and salt and pepper on the insideWrap carefully in greased aluminum foil, two layers, and place over the coals to cook.I also thought of the rotisserie but it seems impractical and I'm afraid I may burn it or dry it outWhat do you recommend?

- Depends on if it has a rhodium plating or notIf it does, take it to whoever you bought it fromNormally sterling comes with some time of care plan so if you have that take it inTarnishing means the rhodium has worn off but it's an easy fix and it comes back looking like new! If you don't have it covered by a jeweler or it doesn't have rhodium plating then just buff it with an infused polishing clothYou can find one at any jewelry storeThis will only delay the tarnishing process though, without rhodium silver will eventually tarnish irreversibly.

Send your message to us

Big Aluminum Foil - Aluminum Foil-Paper Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords