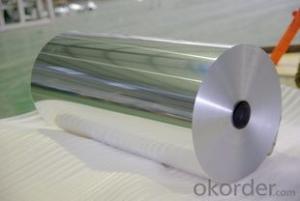

Hot Sale Aluminum Foil Printing - Don't Miss It!

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Secification:

Alloy : AA1235/1050/1060/1100/3003/8011/8006/8079/8021etc.

Temper: H14/16/18/22/24/26, HOetc.

Thickness: 0.006mm—0.20mm

Width: 200mm—1600mm(Can be slitted)

Coating : HSL/Primer

Color : Accordingto customers’ requirements

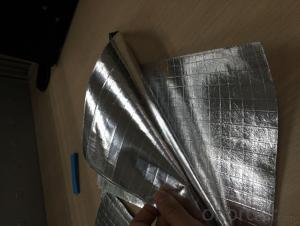

Feature:

100% safe

Environmentally friendly, recoverable and recyclable

Used for storing, packing, grilling/ baking, heating andfreezing

Customized orders available

High-temperature sterilization

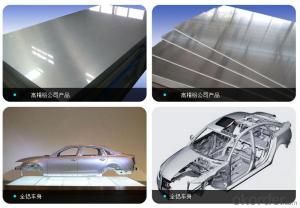

Aplication:

Food Packing, Household Application, Cigarette Packing,Lamination, Medicine , Printing, Heat Sealing, Beer Packing, RoofInsulation Materials, Honeycome Materials and so on.

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

40 day after client’s deposit

- Q: im build a project and i need some help build one because i have to have a marble roll down it but i dont know how any suggestions will help

- Go to a handyman store, or equivalentGet an aluminum tube that has an inside diameter just a bit greater than the diameter of your marbles - and having a thin wallGet a long tube - 6 or seven feet long (approx 2m or more)Get a cylindrical piece of wood, about 6 to 8 inches (15cm to 20cm) diameter and at least 8 inches (20cm) longGet two attachment clamps, omega shaped as used to screw-on that aluminum tube to a wallGet four screws to screw the two clamps to the wooden cylinderGet about half a gallon (2 liters) of fine dry sand and fill the aluminum tube and tape the ends that the sand does not run offUse the two clamps to screw-on the tube one inch from its end to the cylindrical (round) surface of the wooden cylinder near on end of the cylinderAttach the clamps about one inch or less apart from each other so that the tube points tangentially from the cylinderNow fix the free end of the wooden cylinder somewhere so that you can apply force to wind the sand-filled tube around the cylinder in a helical way (screw-like)Note: The sand filling is to avoid collapsing of the tube while winding it aroundWhen you have done your work in winding (approx 3 to 5 turns) you unscrew the two fasteners from the wooden cylinder, you remove the tape from the ends of the tube and you empty the sandRinse the inside of the tube with water and blow it dry with the suction of a vacuum cleanerYou may use the two clamps to fix your helix to the structure of your project.

- Q: 1) What is the total number of s electrons in a single (ground state) K atom?2) What is the principal quantum number (n) for the valence electrons in aluminum?3) If a graph represents the radial probability distribution for an electron in a p-orbital, what is its principal quantum number (n)?Thank you.

- 1If by K you mean potassium, then there are a total of 7 electrons in s orbitals for a neutral, ground (lowest energy) state potassium atomThere are 2 electrons in the 1s state, 2 in the 2s state, 2 in the 3s state, and 1 in the 4s state2The valence electrons in neutral, ground state aluminum are in n33It depends on what the graph looks likeThe graphs of the probability distribution for 2p, 3p, etc look different from each otherThe 2p probability distribution function has 2 lobes, the 3p has 4 lobes.

- Q: Can aluminum foil be utilized as a substitute for a pizza pan?

- <p>Yes, aluminum foil can be used to make a makeshift pizza pan. It's a good alternative when you don't have a pizza stone or pan. Simply prepare a sheet of aluminum foil, ensuring it's large enough to hold the pizza and has some overhang for easy handling. Grease the foil lightly to prevent sticking. While it won't provide the same crispiness as a stone or metal pan, it can still yield a decent pizza. Just be cautious when removing the pizza to avoid tearing it, as foil is less sturdy than a solid pan.</p>

- Q: I need to know every detail.

- That is beautiful bread! Good job! The blob shape may be due to a bit less kneading than you coudl have doneThe more you knead, the more structure the bread will haveBe sure to use bread flour instead of all-purposeAs far as your starter, sounds like it got infected w/ an odd strain of something, and went badYou were right to throw it out.

- Q: forged yellowcake purchase documents- aluminum tubes that can't enrich uranium- mobile chemical weapons labs that never existed- and so on.

- Pass the Kool-ade please, you have obviously had enough.

- Q: I am looking for a potato soup recipe that has a clear brothI don't want anything with cream or dairy in itJust a simple potato/veggie soup that I can make(I got a bunch of potatoes on sale this week and want to cook them up!)I really would like a personal recipe, something that you make and likeI have a wide array of tastes and it can be spicy to just something warming on a cold night! It can be complicated or easy, does not bother me!Thanks!

- Syrup doesn't go bad because it is literally nothing but sugar syrup or corn syrup with some flavoring and coloring addedOnce opened it should be refrigerated, but it could probably keep for a year or moreI have actually had some pancake syrup in my refrigerator for several months and was not afraid to use itSugar and syrups just do not spoil and go bad unless contaminated by something that is dropped inside the containerCorn syrup and Honey can be kept unrefrigerated indefinitely.

- Q: I am rebuilding my trailer due to the frame rusted outI can not find any 2quot;X6' long square steel tubesI had search Home depot, Lowe's, and MenardThey only have 1.5quot;X6'.

- Quality standard for medicinal aluminum tube is correctIt just comes down to the usage of English idiomsFor example, you would say.the standard for good food has just been raisedHowever, you would say the standard of living has gotten worse now.

- Q: what would my best option for a bmx bike be for under $350?

- Such wire from the 60s is/was used in direct contact with insulationIf it was me, I would inspect the wire closely, does the outer sheathing break apart or crumble easily? If there is any reason to think it should be rewired some day I wouldn't cover it upBut if it's in good condition I wouldn't have a problem insulating around it.

- Q: I have made a model of my face by filling a plaster mold of my face with Plaster of ParisI was going to sculpt a mask out of air dry clay, but I ran out and all I have is polymer clayI was wondering if i could bake the plaster along with the clay? Thanks! (The clay package instructions are 270 degrees Fahrenheit.)

- Cris-crossing the two answers and countering Gerald - yes Diane B is fully correct BUT you want the plaster to be fully dry, which may take several days or a trip of its own overnight in an over set lower that 212F, like 200F Once you have felt a dry plaster casting (not set which can be cool and dampish, but dry) you will know it in the futureHeating a damp plaster cast above the boiling point of water can blow pieces off as steam generates inside and can't escape fast enough.

Send your message to us

Hot Sale Aluminum Foil Printing - Don't Miss It!

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords