Aluminum Extrusion Profiles Japanese for LED Strips Lighting Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Led Strips Lighting Project From Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile for Led Strips Lighting Project From:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

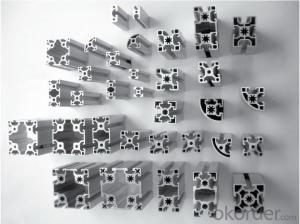

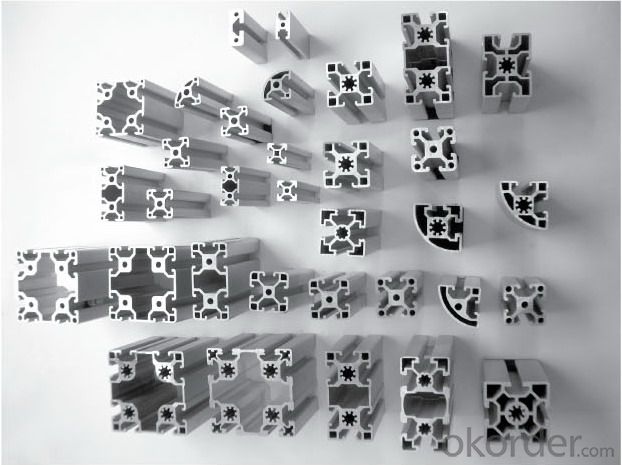

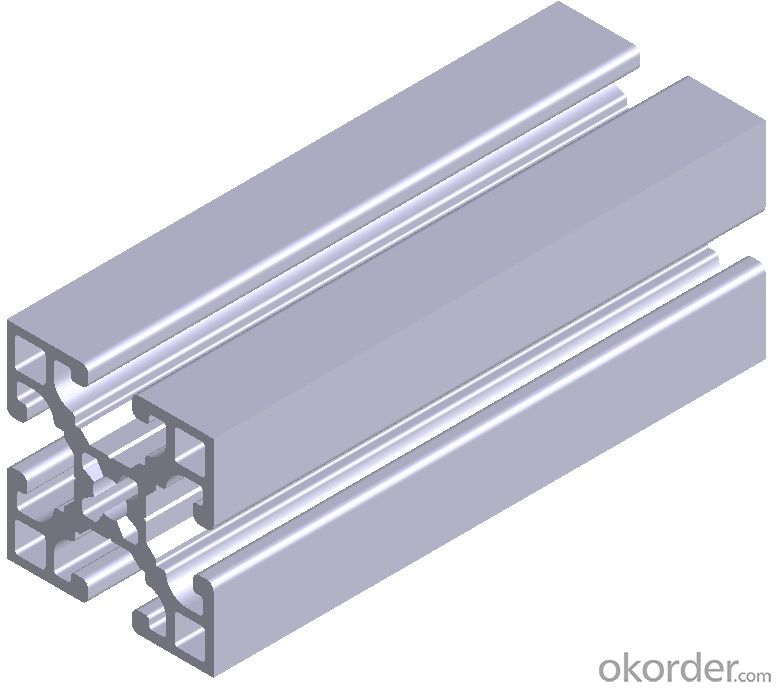

Images of the Aluminium Profile for Led Strips Lighting Project From:

Aluminium Profile for Led Strips Lighting Project From Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: This question asks about the variety of colors offered for aluminum profiles used in exterior siding and trim applications.

- <p>Aluminum profiles for siding and trimming are available in a wide range of colors to suit various architectural styles and design preferences. Common colors include white, black, brown, beige, and gray, which are popular for their neutrality and versatility. Additionally, there are bolder options such as red, blue, green, and yellow for more distinctive looks. Some manufacturers also offer custom color matching services for specific projects. The finishes can be powder-coated or anodized, providing durability and resistance to weathering. It's always best to check with specific manufacturers for the most up-to-date color offerings as they may introduce new colors or discontinue others based on market trends.</p>

- Q: T6 should be 140MPa, while the aluminum profile specification should be 150MPa. Should that be the standard?Code for design of glass curtain wall... And the calculation formula of bolt connection, what is the compressive strength value of aluminum profile?Prawns help you, 3Q~

- When the contact area of the fixture and the clamp decrease, the tension in the tensile process increases, and the change in the force area and bending moment, shear force, etc. will cause the increase of the local stress and the increase of bending moment.

- Q: What are the impact resistance properties of aluminum profiles?

- Aluminum profiles have excellent impact resistance properties due to their inherent strength and durability. They can withstand high impact forces without deforming or breaking, making them suitable for various applications where impact resistance is crucial, such as automotive, construction, and aerospace industries. Additionally, aluminum profiles can absorb and distribute impact energy effectively, minimizing the risk of damage or injury.

- Q: What are the different types of aluminum alloys used for profiles?

- There are several different types of aluminum alloys used for profiles, including 6061, 6063, and 7075. These alloys offer varying levels of strength, corrosion resistance, and machinability, making them suitable for different applications. 6061 is a commonly used alloy for general structural purposes, while 6063 is often used for architectural and decorative applications due to its excellent finishing properties. On the other hand, 7075 is a high-strength alloy primarily used in aerospace and high-performance applications.

- Q: What are the advantages of using aluminum profiles in transportation vehicles?

- Using aluminum profiles in transportation vehicles offers several benefits. To begin with, aluminum is lighter than other metals like steel. This results in reduced fuel consumption and increased energy efficiency, making it perfect for vehicles that require frequent movement and long distances. Moreover, the lightweight nature of aluminum improves maneuverability and handling, enhancing overall vehicle performance. Secondly, aluminum profiles provide excellent corrosion resistance. This is especially important for transportation vehicles that face harsh weather conditions and corrosive elements like salt and moisture. Aluminum's corrosion resistance ensures the vehicle's longevity and durability, reducing maintenance and repair costs. Additionally, aluminum profiles are highly recyclable. The recycling process for aluminum requires less energy compared to producing primary aluminum. This not only reduces greenhouse gas emissions but also contributes to the sustainability of the transportation industry. Aluminum's recyclability aligns with the growing focus on eco-friendly practices. Furthermore, aluminum profiles offer great design flexibility. They can be easily extruded into various shapes and sizes, allowing manufacturers to create customized components and structures for transportation vehicles. This flexibility optimizes space and weight distribution, resulting in improved efficiency and functionality. Lastly, aluminum profiles are non-toxic and non-magnetic. This is advantageous in transportation vehicles as it eliminates the risk of interference with sensitive electronic systems and equipment. Aluminum's non-toxic nature also makes it a safe choice for transporting food and other sensitive materials. In conclusion, there are numerous advantages to using aluminum profiles in transportation vehicles. Its lightweight, corrosion resistance, recyclability, design flexibility, and non-toxic properties make it an ideal material for enhancing fuel efficiency, durability, sustainability, and overall performance in the transportation industry.

- Q: Are aluminum profiles suitable for industrial workstations?

- Yes, aluminum profiles are suitable for industrial workstations. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It is easy to work with and allows for flexibility in design, making it suitable for various industrial applications. Additionally, aluminum profiles can be easily customized and adapted to meet specific workstation requirements, making them a popular choice in industrial settings.

- Q: Are there various ways to install aluminum profiles?

- <p>Yes, aluminum profiles can be installed using different methods. Common installation techniques include direct fastening with screws or bolts, using adhesives or sealants, and employing clip or channel systems. The choice of method depends on the specific application, load-bearing requirements, and aesthetic considerations. Some methods may provide quicker installation, while others might offer better structural integrity or visual appeal. It's important to consult with a professional or follow manufacturer guidelines to ensure the proper installation method is used for the intended application.</p>

- Q: Can aluminum profiles be used for retail displays?

- Indeed, retail displays can utilize aluminum profiles. These profiles possess a remarkable versatility that allows for customization to suit diverse design needs. Notably, they combine lightweight properties with superior strength, rendering them perfect for the construction of robust and enduring retail displays. Furthermore, aluminum profiles lend themselves to effortless shaping, cutting, and assembling, resulting in the creation of distinctive and captivating displays. By employing powder coating or anodization techniques, these profiles can attain a variety of colors and finishes, thereby enhancing the visual appeal of the retail environment. Moreover, through seamless integration with materials like glass, acrylic, or wood, aluminum profiles enable the production of multi-material displays. In conclusion, the remarkable flexibility, durability, and aesthetic charm of aluminum profiles establish them as an excellent choice for retail displays.

- Q: What is the nitriding process of aluminum extrusion die?

- The principle of nitridation:Gas nitrocarburizing, that is gas nitrocarburizing, refers to low temperature nitrocarburizing based on gas nitriding and carburizing. Commonly used media have 50% ammonia, +50% endothermic gas (Nitemper method); 35%-50% ammonia, +50-60% exothermic gas (Nitroc method) and ammonia through the drip ethanol or formamide and so on. In soft nitriding, because of the high solubility of carbon atoms in the epsilon phase, the soft nitrided surface is a common compound of carbon and nitrogen, which is good in toughness and wear resistant.In the process of gas nitrocarburizing, due to the extremely low solubility of carbon atoms, it quickly reaches saturation state and precipitates many super micro cementite points. These cementite particles, as the core of the crystallization of nitrides, contribute to the formation of nitrides. When the surface nitrogen concentration reaches a certain level, the epsilon phase is formed, while the carbon solubility of the epsilon phase is very high, which in turn accelerates the dissolution of carbon.After gas nitrocarburizing, its structure is composed of epsilon phase, gamma phase and nitrogen containing cementite Fe3 (C, N), carbon will reduce the diffusion rate of nitrogen, so the thermal stress and the stress of the tissue are hard, the nitriding is large and the layer is thinner. But at the same time, because the soft nitride layer does not exist. Therefore, the nitride layer, better toughness than hard nitriding

- Q: What are the various standards and regulations governing the use of aluminum profiles in construction?

- <p>Aluminum profiles in construction are governed by a variety of standards and regulations that ensure their quality, safety, and performance. These include ISO standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. National standards like ASTM B221 in the USA and EN 755 in Europe specify mechanical properties and chemical composition. Building codes such as the International Building Code (IBC) and Eurocode 9 also provide guidelines for the use of aluminum in construction. Additionally, there are specific regulations for fire resistance, sustainability, and environmental impact, like the European CE marking for construction products. Compliance with these standards is crucial for manufacturers and builders to ensure the reliability and safety of aluminum profiles used in construction projects.</p>

Send your message to us

Aluminum Extrusion Profiles Japanese for LED Strips Lighting Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords